Magnetic micropore-rich carbon-based cobalt catalyst based on space confinement effect as well as preparation method and application of magnetic micropore-rich carbon-based cobalt catalyst

A technology of carbon-based cobalt catalysts and cobalt catalysts, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxides/metal hydroxide catalysts, etc., can solve the problem of low reaction rate of heterogeneous solid catalysts problems, to achieve the effect of avoiding secondary risk problems, improving catalytic reaction efficiency, and improving degradation or separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing a magnetic microporous carbon-based cobalt catalyst based on a spatial confinement effect, comprising the following steps:

[0041] Step 1, making a solution of divalent cobalt salt, 2-methylimidazole and polyvinylpyrrolidone, mixing and stirring, and synthesizing a modified cobalt-based metal-organic framework material by a hydrothermal method;

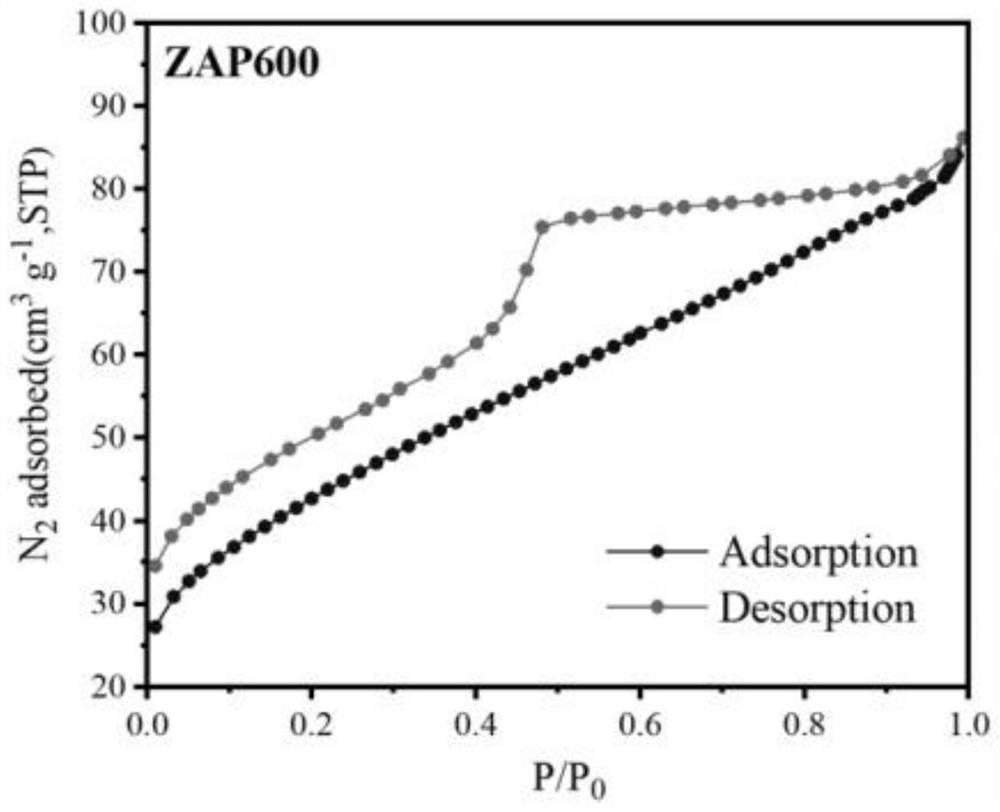

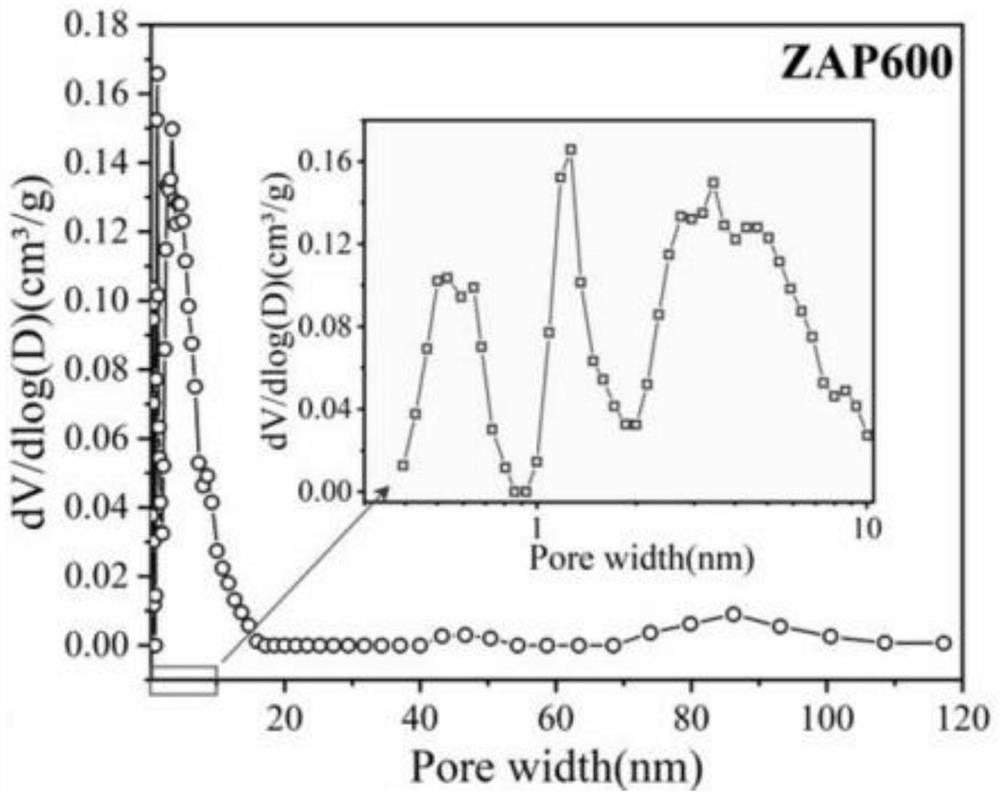

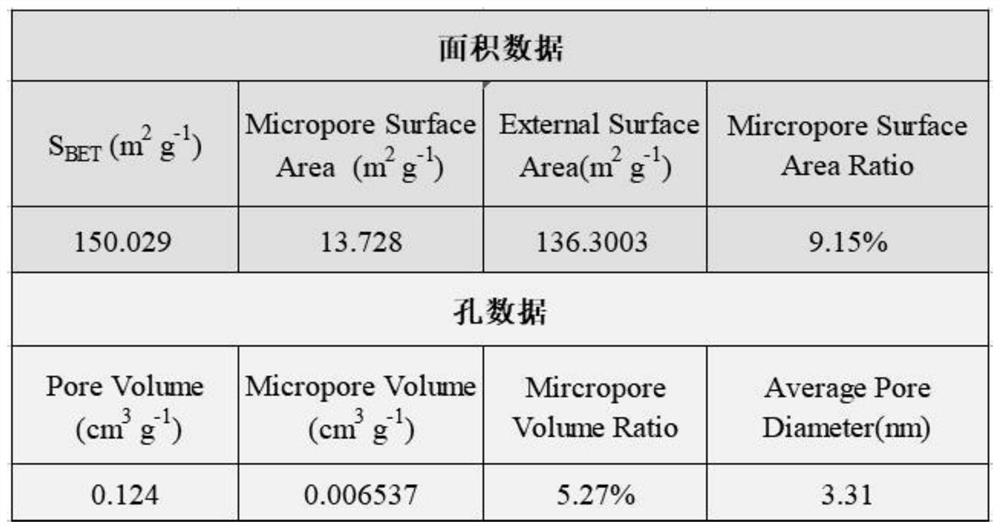

[0042] Step 2, putting the modified cobalt-based metal-organic framework material into a tube furnace for carbonization to obtain a porous carbon-based cobalt catalyst;

[0043] Step 3, using an acid solution to etch the porous carbon-based cobalt catalyst to obtain a magnetic microporous carbon-based cobalt catalyst based on the spatial confinement effect.

[0044] Wherein, the divalent cobalt salt includes cobalt nitrate hexahydrate or cobalt chloride hexahydrate, the mass ratio of the divalent cobalt salt to 2-methylimidazole is 1:11-12, and the acid solution includes nitric acid solution or hydrochlo...

Embodiment 2

[0057] The difference from Example 1 is that in this example, 2.0 g of the modified cobalt-based metal-organic framework material was placed in a nitrogen atmosphere, carbonized at a temperature of 700 ° C for 2 hours, and the heating condition was 10 ° C / min, and the whole process was placed in nitrogen In the ambient environment, the porous carbon-based cobalt catalyst was obtained after cooling to room temperature.

[0058] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0060] The difference from Example 1 is that in this example, 2.0 g of the modified cobalt-based metal-organic framework material was placed in a nitrogen atmosphere, and carbonized at a temperature of 800 ° C for 2 hours. The heating condition was 10 ° C / min, and the whole process was placed in nitrogen In the ambient environment, the porous carbon-based cobalt catalyst was obtained after cooling to room temperature.

[0061] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com