Method for treating biosurfactant soil eluent based on FM-SBC/SPC system

A biological surface and active agent technology, applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of simultaneous removal of heavy metals and polycyclic aromatic hydrocarbons, biosurfactant loss, Solve the problems of high process cost and achieve the effect of low loss, low preparation cost and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A method for processing biosurfactant soil eluent based on FM-SBC / SPC system, comprising steps as follows:

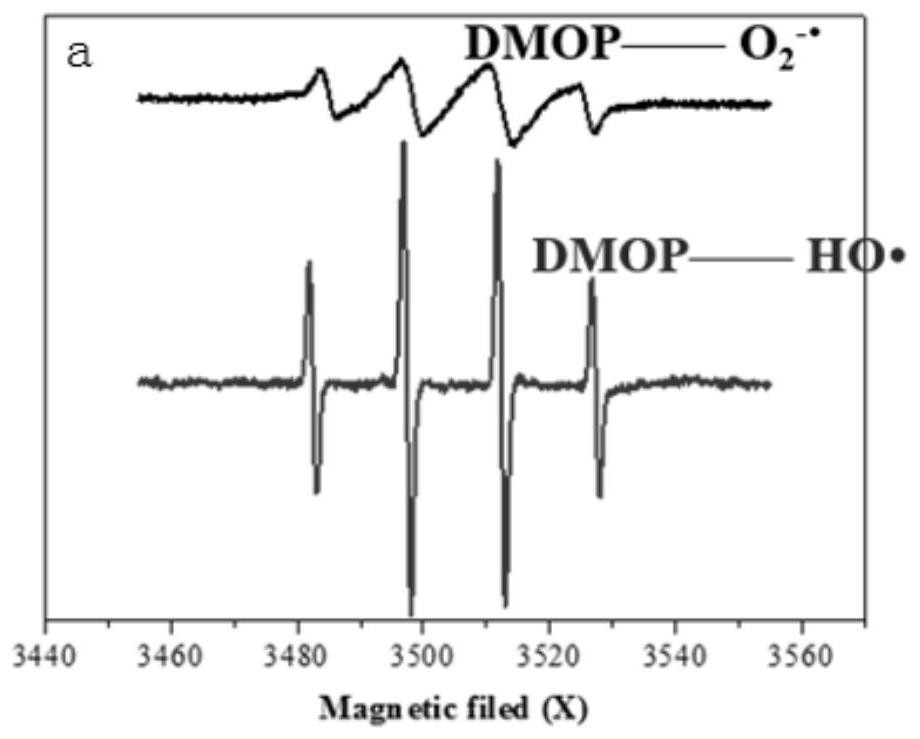

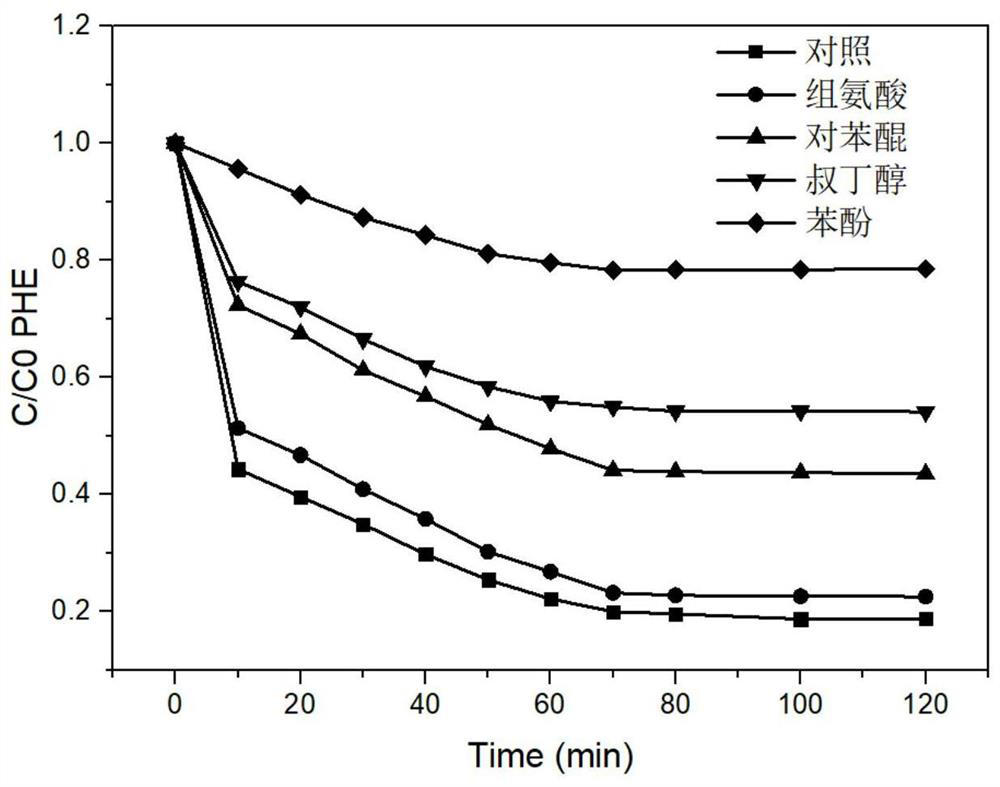

[0050] Add magnetized sulfur modified biochar FM-SBC to biosurfactant soil eluent, add sodium percarbonate SPC at the same time, shake and react for 120min, the pH of the system is 7 during the reaction process, and the magnetized sulfur modified biochar FM-SBC adsorbs heavy metals, and the active site of magnetized sulfur modified biochar FM-SBC does not change, and activates sodium percarbonate SPC to generate free radicals to achieve the degradation of polycyclic aromatic hydrocarbons;

[0051] The dosage of magnetic sulfur modified biochar FM-SBC is 1.5g / L, and the dosage of sodium percarbonate SPC is 1.5g / L.

[0052] Magnetized sulfur modified biochar is prepared as follows:

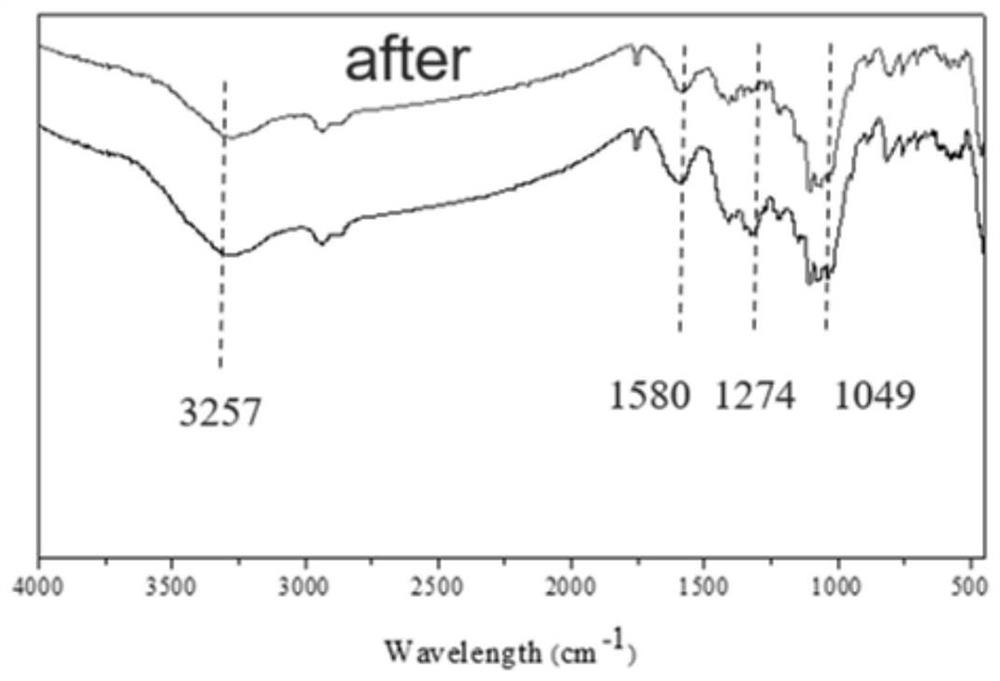

[0053] The collected wheat straw was washed and dried, ground and passed through a 200-mesh sieve, and heated to 500 °C at 10 °C / min in a nitrogen atmosphere, and kept for 2 hours, th...

Embodiment 2

[0056] With the method for processing biosurfactant soil eluent based on FM-SBC / SPC system described in embodiment 1, difference is:

[0057] The dosage of sodium percarbonate SPC is 1g / L.

Embodiment 3

[0059] With the method for processing biosurfactant soil eluent based on FM-SBC / SPC system described in embodiment 1, difference is:

[0060] The dosage of sodium percarbonate SPC is 2g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com