Recycled concrete replaced by brick-concrete recycled coarse aggregate and preparation method of recycled concrete

A technology of recycled concrete and recycled coarse aggregate, applied in the field of concrete, can solve the problems of large dispersion of aggregate performance, high labor cost, and difficulty in resource utilization, etc., and achieve excellent cube compressive strength and excellent axial compressive strength. , to achieve the effect of resource application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0162] Example 1 Performance test of brick-mixed recycled coarse and fine aggregate

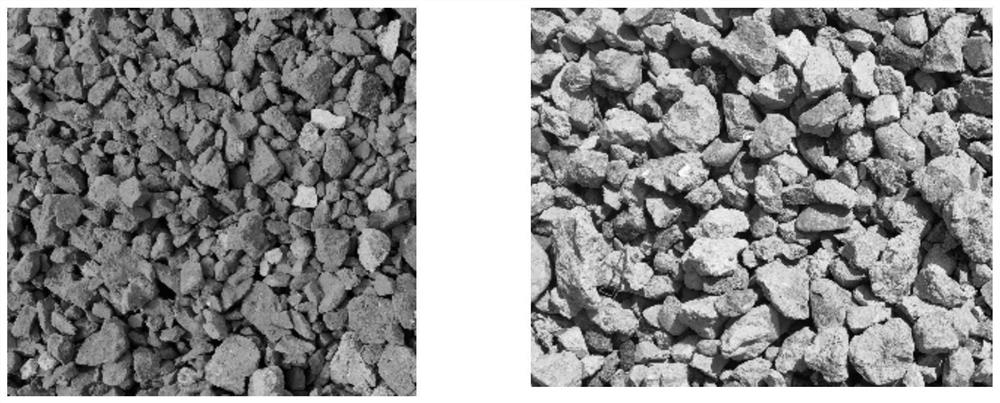

[0163] The recycled aggregate used in this test is from Beijing Construction Engineering Resource Company. The aggregate is divided into recycled concrete coarse aggregate and recycled red brick coarse aggregate according to particle size and raw materials, such as figure 1 shown.

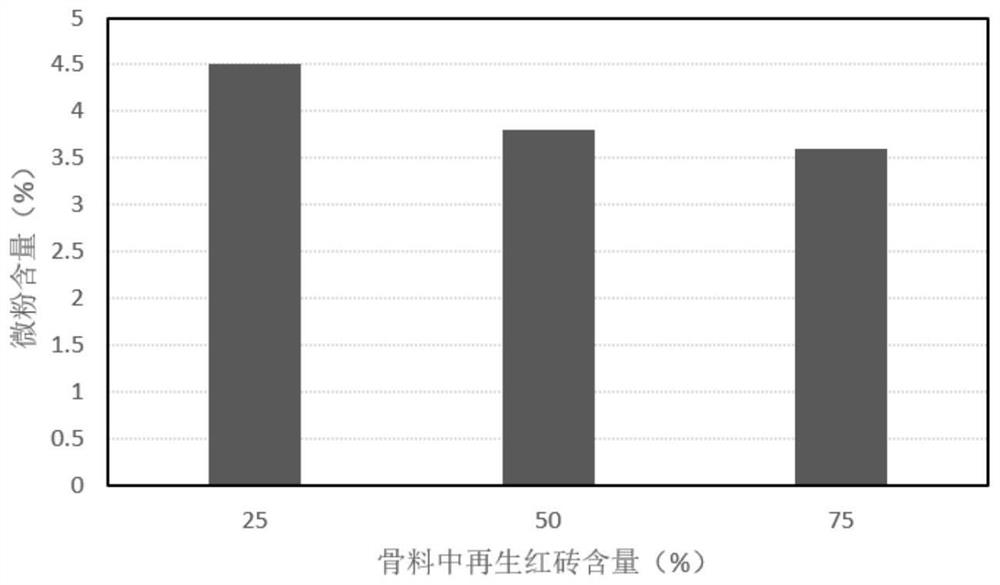

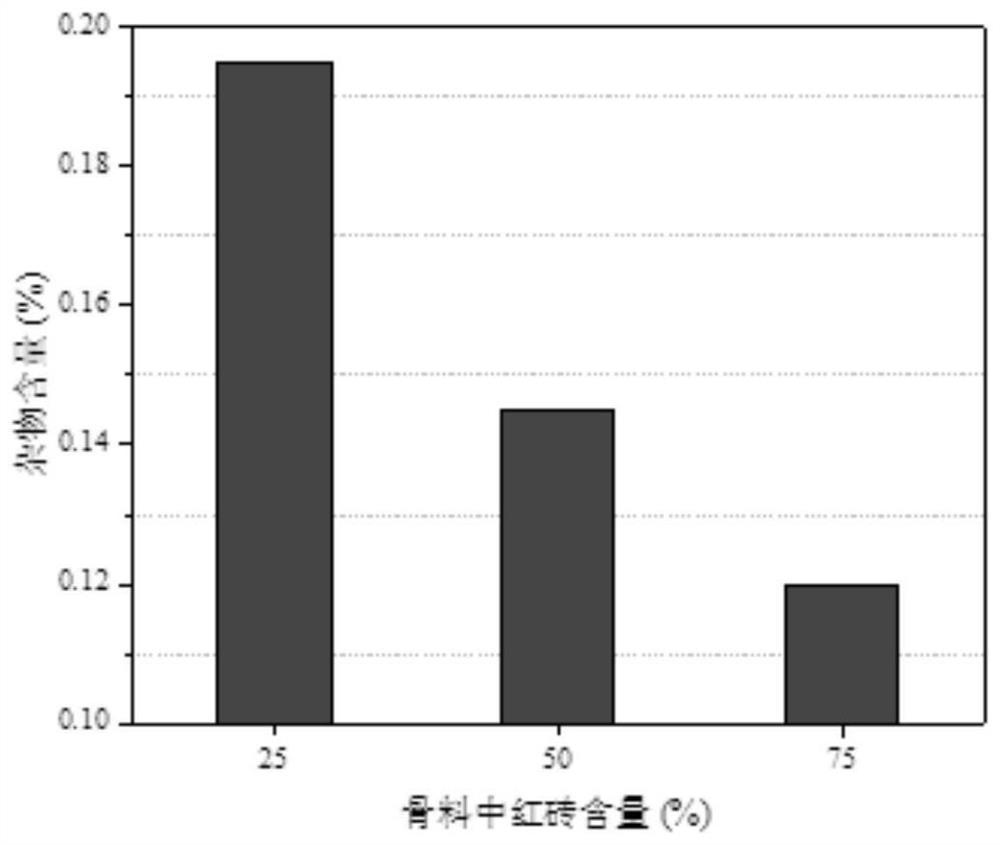

[0164] After drying the obtained recycled aggregate, according to the mass ratio of recycled red brick aggregate of 25%, 50%, 75% and recycled concrete aggregate, three kinds of brick-mixed fully recycled coarse bone can be obtained. The performance tests were carried out on fully recycled coarse aggregates with different brick contents; mainly including: particle gradation, harmful substance content, fine powder and mud content, firmness, crushing index, apparent density, bulk density and void ratio and other indicators.

[0165] (1) Particle gradation

[0166] For particle gradation of recycled coarse aggrega...

Embodiment 2

[0193] The preparation of embodiment 2 recycled concrete

[0194] According to the test results of recycled aggregates, two kinds of brick-mixed recycled coarse aggregates (red brick content 50% and 75%) were selected respectively, and the recycled brick-mixed coarse aggregates were used to replace natural coarse aggregates to form recycled concrete; different substitution ratios were explored , the substitution method of coarse aggregate and the influence of different brick contents in the coarse aggregate on the strength, work performance (slump, expansion and loss over time) and freeze-thaw resistance (mass loss and strength loss) of recycled concrete at different ages .

[0195] The proportion of recycled concrete foundation is shown in Table 13. The total water consumption is kept constant in the test, and the slump is adjusted by adjusting the amount of water reducing agent. The slump is controlled at 20±2mm and the expansion is 45±3mm. The water reducer used in the exp...

Embodiment 3

[0201] Performance test of embodiment 3 recycled concrete

[0202] (1) Slump

[0203] The concrete test of the present invention controls the slump to about 20cm by adjusting the amount of water reducing agent. Therefore, the difference in slump of each group in this paper is small, all about 20cm. The detailed data is shown in Table 15 below.

[0204] Table 15 The slump of recycled concrete and the dosage of water reducer under the replacement of coarse aggregate

[0205]

[0206] It can be seen from the data that, under the condition of keeping the water consumption constant, with the increase of the measured aggregate replacement rate, the amount of recycled concrete superplasticizer also gradually increases, and the higher the content of red brick in the aggregate, the less water-reducing agent is required. The more liquids.

[0207] (2) Extensibility

[0208] Table 16 shows the results of expansion degree and time-lapse expansion degree and the amount of water reduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com