Star-branched ternary integrated rubber prepared through catalysis of mono-scandium-cyclopentadienyl rare earth catalyst and preparation method of star-branched ternary integrated rubber

A rare earth catalyst and branched ternary technology, which is applied in the synthesis of functionalized integrated rubber materials, can solve the problems of poor compatibility, high energy consumption, rubber matrix and filler, etc., and achieve easy synthesis, stable valence state, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1 Preparation of macromonomer core A1 containing multiple dangling double bonds (A:B=1, branching agent monomer concentration 3.8g / 100ml, [Si] / [Sc] is 20)

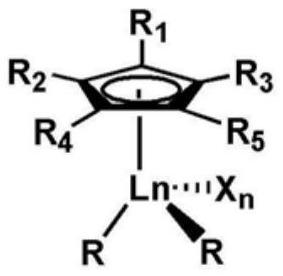

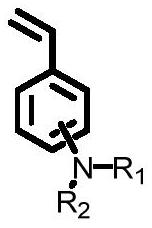

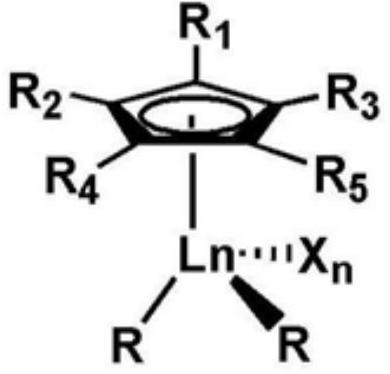

[0048] In a glove box under nitrogen protection, a magnetic stir bar was placed in a 100mL round-bottomed flask, and 30.6mg (60μmol) of scandium monocene rare earth catalyst (C 5 Me 4 SiMe 3 )Sc(CH 2 C 6 h 4 NMe 2 -o) 2 , then add 55.5mg (60μmol) [Ph 3 C][B(C 6 f 5 ) 4 ], add 2mL of toluene solvent under stirring, add 0.230g (1.2mmol) dimethyl dipentadienyl silane under vigorous stirring, react at room temperature for 3min, the molar ratio of dimethyl dipentadienyl silane and rare earth catalyst [Si ] / [Sc] is 20. After the polymerization is complete, take the round bottom flask out of the glove box, add a small amount of methanol to terminate the reaction, then pour a large amount of methanol into the terminated reaction solution, wash the precipitated polymer with methanol, and dry it in a vacuum...

Embodiment 2

[0049] Example 2 Preparation of macromonomer core A2 containing multiple dangling double bonds (A:B=1, branching agent monomer concentration 3.8g / 100ml, [Si] / [Sc] is 20)

[0050] The reaction was carried out at room temperature for 10 minutes, and other polymerization conditions were the same as in Example 1 to obtain a macromonomer core A2 containing multiple pendant double bonds. Polymer structure analysis result is as follows: productive rate is 90% (mass percentage), molecular weight M w 14.3×10 3 g / mol, molecular weight distribution index M w / M n is 3.97, the structure content of the pendant double bond is 41% (mole percent), and the gel content is 10% (mass percent).

Embodiment 3

[0051] Example 3 Preparation of macromonomer core B1 containing multiple dangling double bonds (A:B=1, branching agent monomer concentration 3.8g / 100ml, [Si] / [Sc] is 20)

[0052] In the 100mL round-bottomed flask, a magnetic stirring bar was put into it, and 30.6mg (60 μmol) of a monocene scandium rare-earth catalyst (C 5 h 5 )Sc(CH 2 C 6 h 4 NMe 2 -o) 2 , reacted at room temperature for 10 min, and other polymerization conditions were the same as in Example 1 to obtain a macromonomer core B1 containing multiple pendant double bonds. Polymer structure analysis result is as follows: productive rate is 30% (mass percentage), molecular weight M w 5.0×10 3 g / mol, molecular weight distribution index M w / M n is 1.31, the structure content of the pendant double bond is 87% (mole percent), and the gel content is 0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com