A kind of preparation method and application of vanadium trioxide negative electrode material

A technology of negative electrode material and ammonium vanadate, which is applied in the field of preparation of vanadium trioxide negative electrode material, can solve the problems of high temperature, long preparation period, large energy consumption, etc., and achieves high consumption, high equipment cost and safety factor. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

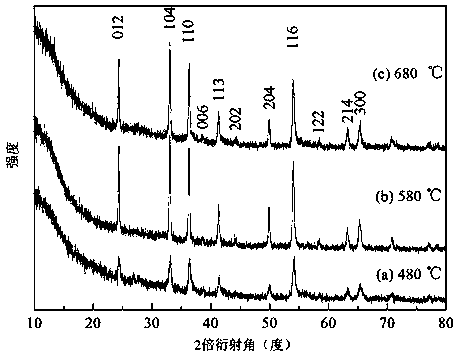

Embodiment 1

[0029] (1)V 2 o 3 Preparation of negative electrode material:

[0030] a Cut a silicon wafer, place the silicon wafer in a beaker filled with ethanol, perform ultrasonic cleaning, and then use acetone to perform ultrasonic cleaning to remove impurities on the silicon wafer, and finally dry the silicon wafer and place it on graphite side of the crucible.

[0031] b Weigh 2mmol (0.234g) of ammonium metavanadate (NH 4 VO 3 ) powder, spread the powder on the smooth side of the silicon wafer; take 10mmol (0.07g) of lithium wafer and place it on the other side of the graphite crucible.

[0032] c Finally, put the crucible into the tube furnace, with the side with the lithium sheet facing the direction of the air inlet, pass high-purity nitrogen gas for high-temperature calcination, the calcination temperature is 480°C, the heating rate is 5°C / min, and the temperature is kept for 2h. After the calcination is completed, it is naturally cooled to room temperature to prepare V 2 o...

Embodiment 2

[0038] In Example 1, the pure nitrogen was changed to pure helium, the calcination temperature was changed from 480°C to 580°C, and other reaction conditions and performance testing methods were exactly the same as in Example 1.

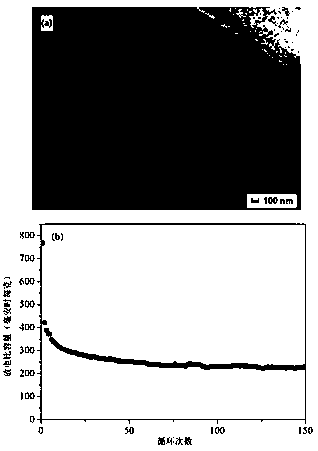

[0039] image 3 a is V in Example 2 2 o 3 The scanning electron microscope (SEM) spectrum of the negative electrode material, it can be seen from the figure that the shape of the material is a broken block, and it can be clearly observed that the block material is composed of many particles. The average block size is about 9 microns, and the grain size of the particles is 32.39 nm. It shows that with the increase of temperature, the material decomposes further.

[0040] image 3 b is the discharge cycle specific capacity curve of the material of Example 2. Under the current density of 100mA / g, the discharge specific capacity decreased significantly in the first 30 weeks, and then gradually stabilized. After 150 weeks of charge and discharge cycle...

Embodiment 3

[0042] In Example 1, the pure nitrogen gas was changed to pure neon gas, the calcination temperature was changed from 480° C. to 680° C., and other reaction conditions and performance testing methods were exactly the same as those in Example 1.

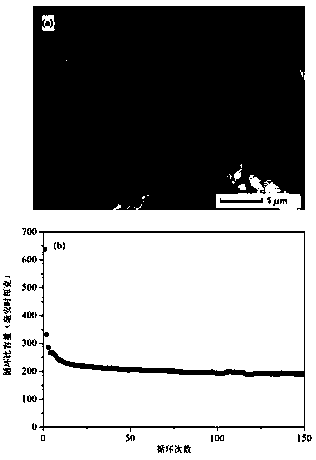

[0043] Figure 4 a is V in Example 3 2 o 3 The scanning electron microscope (SEM) spectrum of the negative electrode material, from which it can be observed that V 2 o 3 The shape of the negative electrode material is completely granular, the average particle size of the particles is about 0.25 microns, and the grain size is 29.73 nanometers. It shows that when calcined at 680℃, the material is completely decomposed from block to granular, and the calcining temperature has a great influence on the morphology and structure of the material.

[0044] Figure 4 b is V in Example 3 2 o 3 The discharge cycle specific capacity curve of the negative electrode material shows that at a current density of 100mA / g, the discharge specific c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com