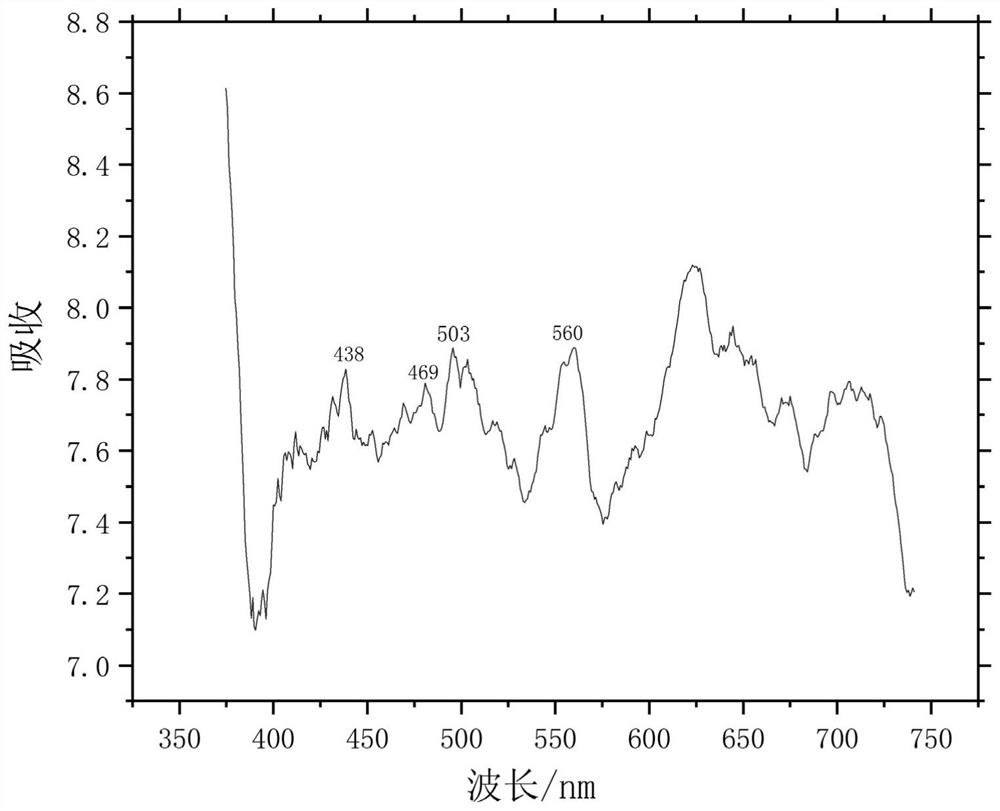

Imitated jewel photochromic glass with excellent performance, and preparation method and application thereof

A technology for color-changing glass and imitation gemstones, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problem of expensive gemstones, and achieve the effects of good chemical stability, low lead content, and low production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

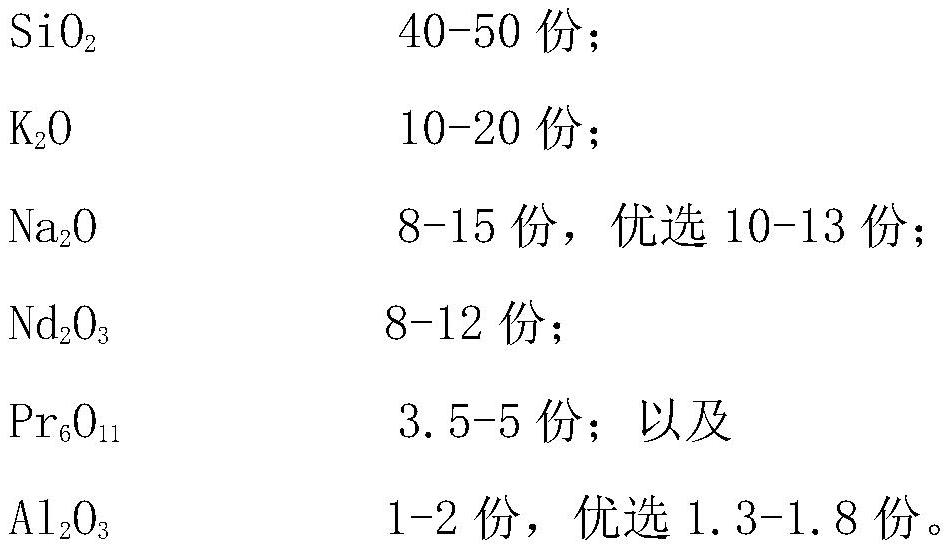

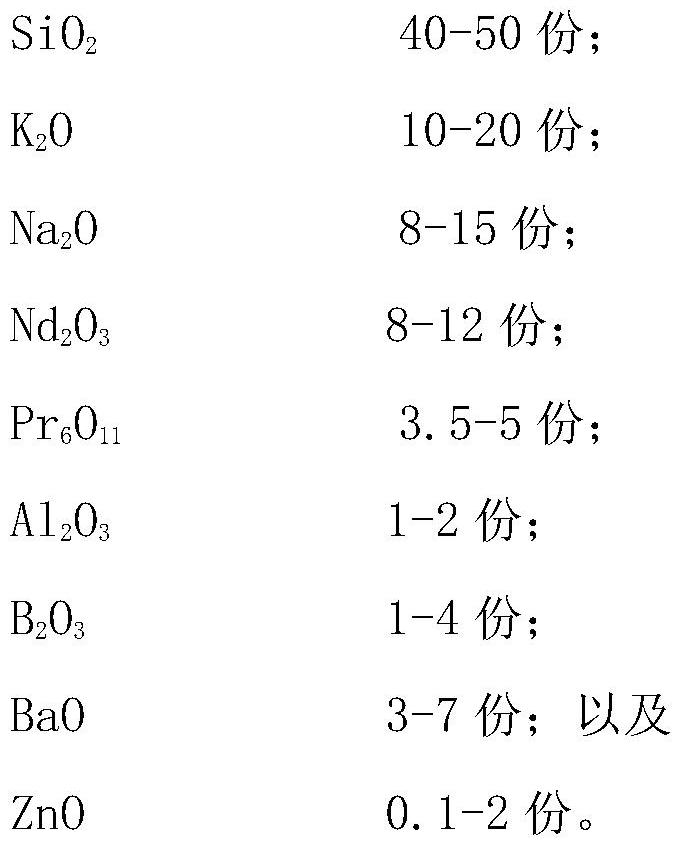

[0064] The imitation jewel color-changing glass of the present embodiment is made of the following raw materials: by weight, silicon dioxide SiO 2 47 parts potassium carbonate K 2 CO 3 22.5 parts, sodium nitrate NaNO 3 32.5 parts, neodymium trioxide Nd 2 o 3 9 parts, praseodymium oxide Pr 6 o 11 4 parts, borax Na 2 B 4 o 7 10H 2 O 8 parts, barium oxide BaO 5 parts, lead oxide PbO 0 parts, aluminum oxide Al 2 o 3 1.5 parts, 1 part of zinc oxide ZnO.

[0065] Preparation:

[0066] Grind the above raw materials and evenly mix them into a batch, and put the batch into a platinum-rhodium alloy crucible. Afterwards, the platinum-rhodium alloy crucible was placed in a high-temperature electric furnace and heated to a melting temperature of 1650° C. at a heating rate of 15° C. / min, and kept for 1 hour to obtain a melt. After pouring the molten body into the cast iron mold, put it into the heat preservation electric furnace for annealing quickly, the annealing tempe...

Embodiment 2

[0075] The imitation jewel color-changing glass of the present embodiment is made of the following raw materials: by weight, silicon dioxide SiO 2 48 parts potassium carbonate K 2 CO 3 25 parts, sodium nitrate NaNO 3 27 parts, neodymium trioxide Nd 2 o 3 9 parts, praseodymium oxide Pr 6 o 11 2.5 parts, borax Na 2 B 4 o 7 10H 2 O 6.5 parts, barium oxide BaO 6 parts, lead oxide PbO 0 parts, aluminum oxide Al 2 o 3 2 parts, 1 part of zinc oxide ZnO.

[0076] Preparation:

[0077] Grind the above raw materials and evenly mix them into a batch, and put the batch into a corundum crucible. Afterwards, put the corundum crucible into a high-temperature electric furnace and heat it to a melting temperature of 1400°C at a heating rate of 5°C / min to melt the glass, and keep the temperature for 1-4 hours to obtain a melt. After pouring the molten body into the cast iron mold, put it into the heat preservation electric furnace for annealing quickly, the annealing tempera...

Embodiment 3

[0082] The imitation jewel color-changing glass of the present embodiment is made of the following raw materials: by weight, silicon dioxide SiO 2 47.5 parts, potassium carbonate K 2 CO 3 21 parts, sodium nitrate NaNO 3 26 parts, neodymium trioxide Nd 2 o 3 9.5 parts, praseodymium oxide Pr 6 o 11 5 parts, borax Na 2 B 4 O7·10H 2 O 6 parts, barium oxide BaO 3.5 parts, lead oxide PbO 3 parts, aluminum oxide Al 2o 3 2 parts, 1 part of zinc oxide ZnO.

[0083] Preparation:

[0084] Grind the above raw materials and uniformly mix them into a batch, and put the batch into a platinum-rhodium alloy crucible. Afterwards, the platinum-rhodium alloy crucible was put into a high-temperature electric furnace and heated to a melting temperature of 1450° C. at a heating rate of 10° C. / min, and kept for 3.5 hours to obtain a melt. After pouring the molten body into the cast iron mold, put it into the heat preservation electric furnace for annealing quickly, the annealing te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com