Preparation method of high-strength silicon alloy lithium battery negative electrode material

A technology of negative electrode material and silicon alloy, applied in the direction of negative electrode, battery electrode, active material electrode, etc., can solve the problem of low mechanical strength, and achieve the effect of high mechanical strength, high mechanical elasticity and low cost

Pending Publication Date: 2022-03-18

南京宇博瑞材料科技有限公司

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The invention aims to overcome the problem of low mechanical strength of existing silicon alloys, and provides a method for preparing a high-strength silicon alloy lithium battery negative electrode material

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

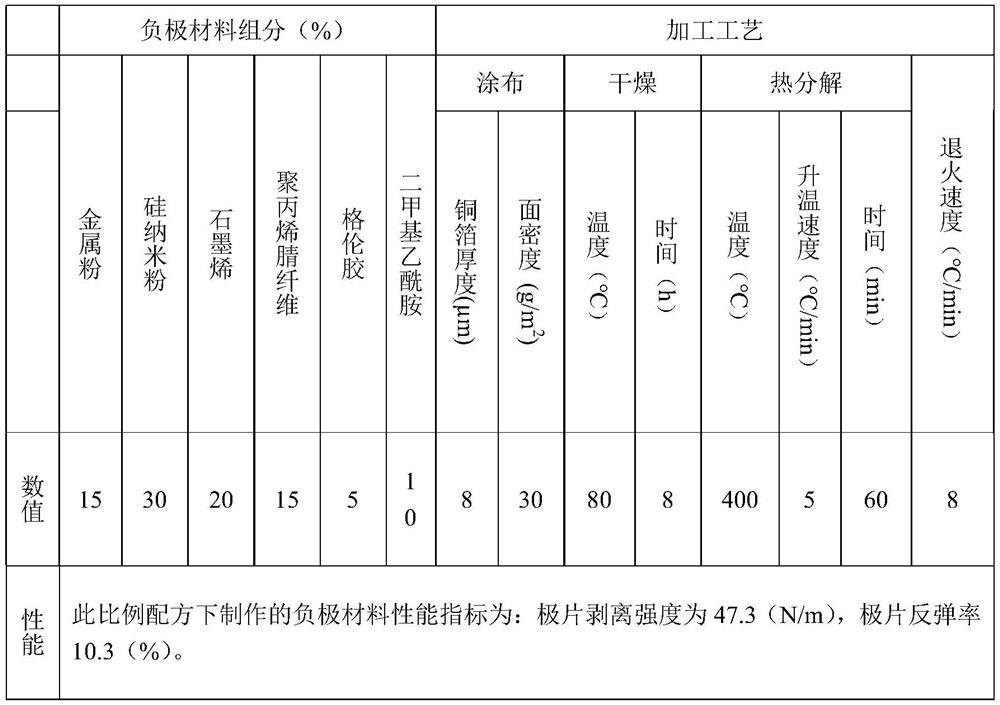

Embodiment example 1

[0031]

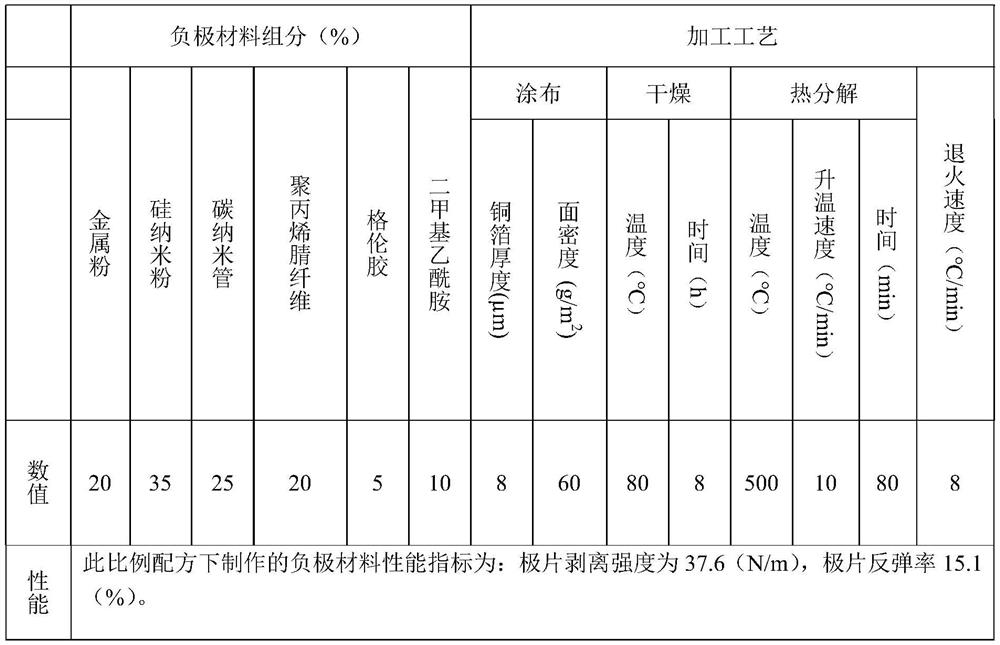

Embodiment example 2

[0033]

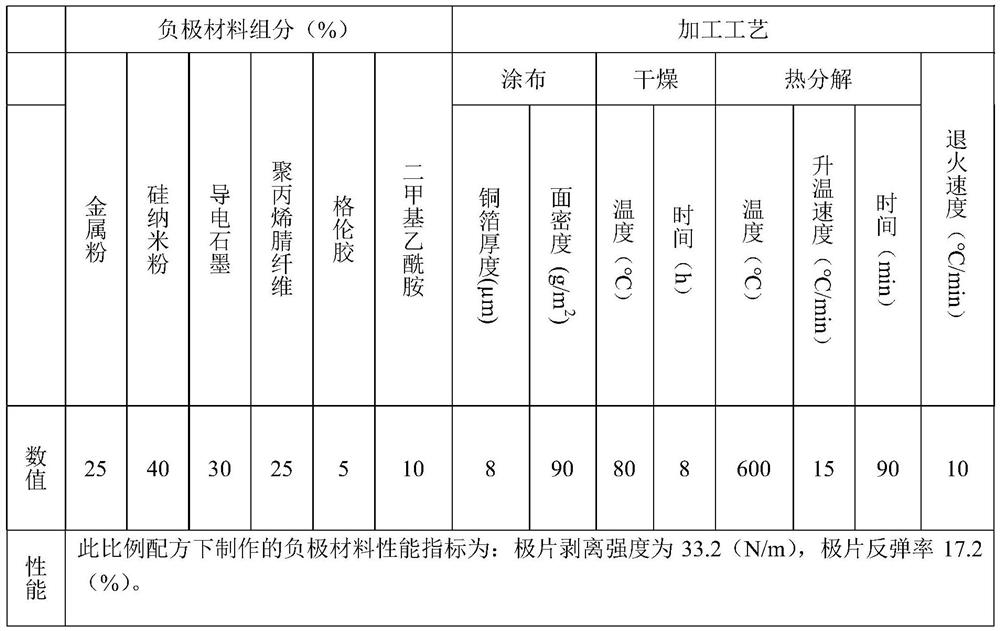

Embodiment example 3

[0035]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a high-strength silicon alloy lithium battery negative electrode material and a preparation method thereof, and the preparation method mainly comprises the following steps: mixing and crushing raw materials (metal powder, silicon nano powder, a carbon material, polyacrylonitrile fiber and Gelon gum), and adding dimethylacetamide for grinding; coating a copper foil with the ground mixture, and carrying out vacuum drying; and then carrying out thermal decomposition treatment on the dried copper foil and annealing to room temperature. The electrode material prepared by the invention has relatively high mechanical strength; the silicon volume change in the battery charging and discharging process is effectively relieved; the graphene-coated silicon particles with high mechanical elasticity are favorable for adapting to obvious volume change.

Description

technical field [0001] The invention relates to the field of negative electrode materials for lithium batteries, in particular to a preparation method for a high-strength silicon alloy lithium battery negative electrode material. Background technique [0002] Due to the huge volume change of silicon particles during the charging and discharging process of lithium batteries, that is, large particles transform into small particles, the conductivity of the electrode decreases, and an unstable solid electrolyte film (SEI) forms on the silicon surface, resulting in a rapid decline in battery capacity. Studies have shown that silicon is resistant to particle breakage below a critical size of 150nm, the size of particles that help maintain electrode integrity. In addition, the small particles can shorten the length of the lithium ion diffusion path and improve the rate capability. Therefore, constructing a composite silicon anode with an appropriate size is an important way to imp...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M4/139H01M4/13H01M4/38H01M4/62H01M10/0525

CPCH01M4/386H01M4/625H01M4/621H01M4/628H01M4/13H01M4/139H01M10/0525H01M2004/027Y02E60/10

Inventor 陈家禄何倩陈子博韩旭然史丽

Owner 南京宇博瑞材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com