Bio-based olefin oligomerization with chabazite catalysts

A catalyst, chabazite technology, applied in the direction of catalyst regeneration/reactivation, catalyst, molecular sieve catalyst, etc., can solve the problems of poor cold flow characteristics, decreased fluidity, filter blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Example 1: No Oxygenates and No Recycle Feed

[0065] Catalyst: Clariant TiAPSO-34, total WHSV=2; reactor top temperature 180-185°C; P(psig)=250; 2.9g Client TiAPSO-34 (granular particles)+glass beads; mass ratio=97.4%; Feed: 88% iC4, 6% cis-2-butene, 6% trans-2-butene.

[0066] As shown in Table 1 below, C 8 The percentage of oligomers is about 40%, C 12 The percentage of oligomers is about 50%. In addition, C 8 And the percentage of higher carbon chain (C8+) oligomers is about 95%. C 8 relative C 12 and larger oligomers with a selectivity of 0.69:1, and C 8 -C 24 The yield of hydrocarbons is greater than 95%. C 8 Hydrocarbon yield greater than 39%, C 12 The yield of hydrocarbons was greater than 49%.

[0067] Table 1: Reaction oligomer product distribution:

[0068] %C4 %C5-C7 %C8 %C9-C11 %C12 %C13-C15 %C16 %C20 %C24 3.96 0.42 39.04 0.35 49.26 0.12 6.43 0.41 0.01

Embodiment 2

[0069] Example 2: Presence of oxygenates and recycled feed

[0070] Catalyst: Clariant TiAPSO-34, total WHSV=3.2, recycle feed: the mass ratio of fresh feed is 3: 1; Reactor top product concentration 180-185 ℃, P (psig)=250; 2.9g Clariant TiAPSO-34 ( Granular particles) + glass microspheres; mass ratio = 97.0%; oxygenates in recycled feed: 200ppm water, 6070ppm (isobutanol and tert-butanol); feed: 88% iC4, 6% cis-2- Butene, 6% trans-2-butene.

[0071] Table 2 illustrates the distribution of carbon oligomers where the feed stream contains oxygenates such as alcohols and water and about 25% of the feed stream contains recycle feed. The recycle feed contains about 37% C 8 oligomers and about 47% C 12 Oligomer. In the recycle feed C 8 The percentage of + oligomers was greater than 92%, lower than the overall yield in Example 1. In the product stream, C 8 The amount of oligomers decreased slightly, while C 12 The amount of oligomers increased slightly. This example illustr...

Embodiment 3

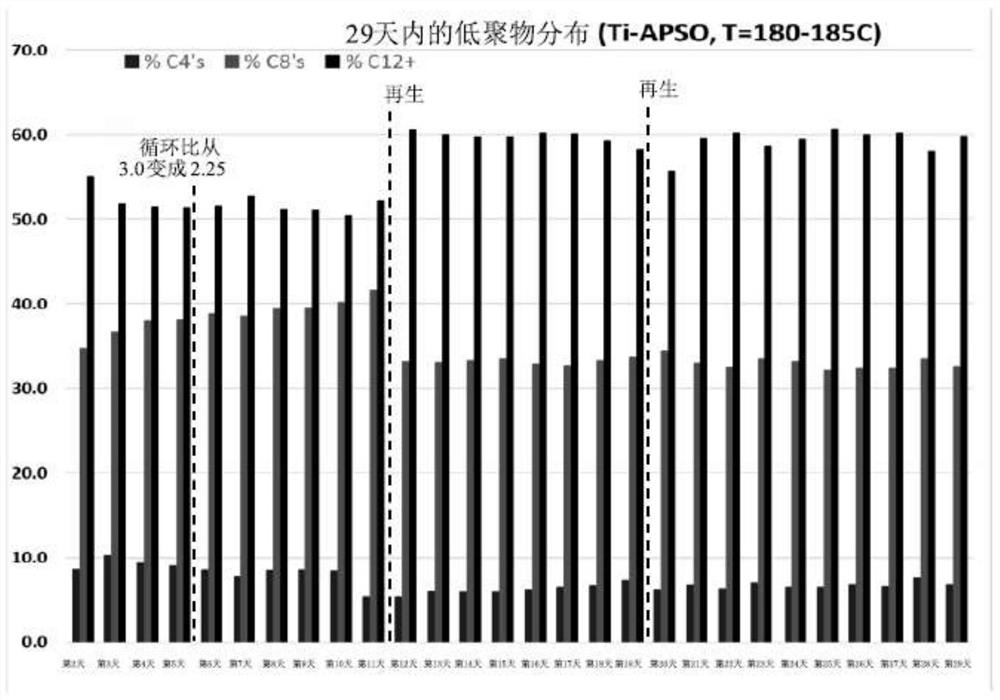

[0077] Example 3: Extended On Time (TOS) in the Presence of Oxygenates and Multiple Catalyst Regenerations

[0078] Catalyst: Clariant TiAPSO-34, total WHSV=2.6, recycle feed: the mass ratio of fresh feed is 2: 1; Reactor top temperature 180-185 ℃, P (psig)=250; 2.9g Clariant TiAPSO-34 (granular Granules) + glass microspheres; typical mass proportion = 97.0%; total oxygenates in feed: 100 ppm water, 1800 ppm (mass ratio of isobutanol and tert-butanol is 85 / 15).

[0079] Table 3 below shows that C 8 and C 12+ The percentages of oligomers are in the range of 30%-45% and 50%-65%, respectively. Surprisingly, the catalyst can be used for at least 10 days without regeneration and still produce acceptable yields of C 8 and C 12 Oligomer. Also surprisingly, the catalyst is also regenerable in air and can be used for long periods of time without the need for regeneration. C 8 +Oligomer selectivity and high yield, long catalyst life without replacement and long catalyst regenerat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com