Catalyst regeneration method

A technology of catalysts and prepared catalysts, which is applied in the direction of catalysts, molecular sieve catalysts, carbon compound catalysts, etc., to achieve the effect of increasing the yield of low-carbon olefins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

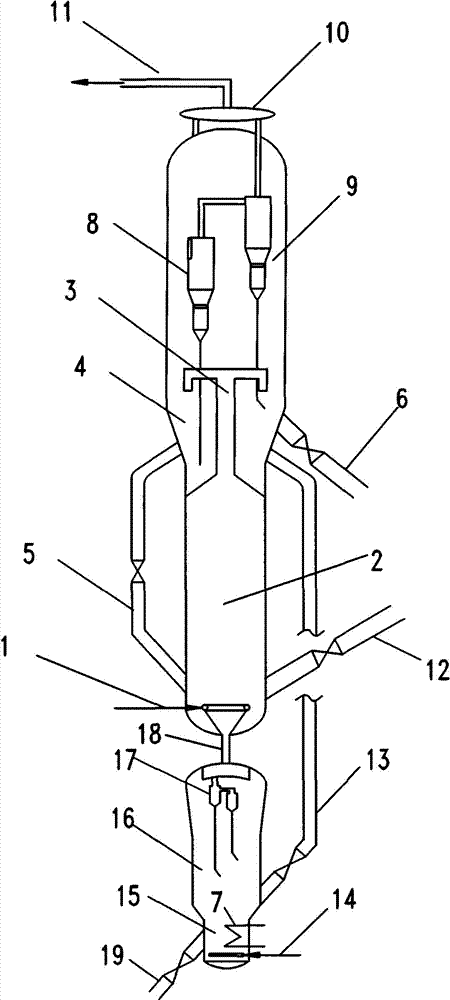

[0015] in such as figure 1 In the regeneration device shown, the mass fraction of carbon deposits in the catalyst to be regenerated is 4.5%, the first regeneration zone is a fast fluidized bed, and the regeneration temperature is 648°C, and the second regeneration zone is a dense-phase fluidized bed, and the regeneration temperature is It is 682°C, and a heat extraction coil is installed inside to control the regeneration temperature. Nitrogen is supplemented in the first regeneration zone, and the oxygen concentration is controlled to be 5.98%. The regeneration medium in the second regeneration zone is air, and 40% of the regenerated catalyst I enters the second regeneration zone. Two regeneration zones, 60% demethanol to olefins reactor, methanol to olefins reactor reaction conditions are: temperature of reaction is 475 ℃, and gas phase linear velocity is 1.25 m / s, and the average carbon deposit of catalyst is 3.2% (weight), The regenerated catalyst II is used for the cataly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com