Culture system and method for large-scale production of cultured food

A culture system and food technology, applied in the field of cultured meat and the manufacture of cultured meat, can solve problems such as expanding the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0235] Example 1: Production of cultured meat fractions

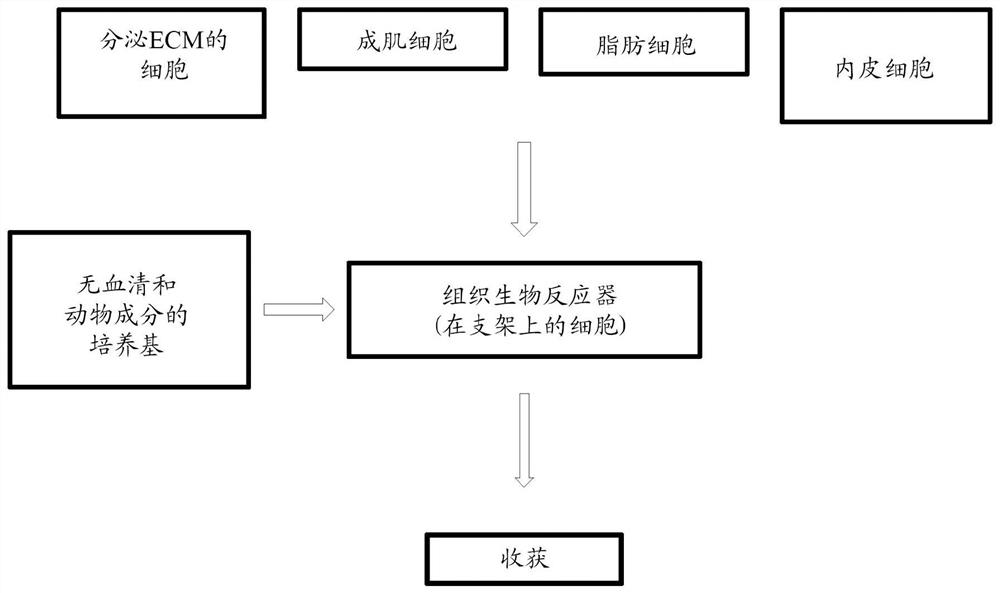

[0236] Process flow chart such as image 3 depicted in .

[0237] Progenitors of bovine-derived ECM-secreting cells, myoblasts, adipocytes, and endothelial cells were obtained differentiated from bovine PSCs. According to the present invention, differentiated cells are seeded on scaffolds having a protein content of at least 40% by weight (dry weight) in a cell culture bioreactor and cultured in the culture system described herein for 10-14 days . Forms part of the cultured meat.

[0238] Partially differentiated cells were seeded on the scaffold in a set ratio between the four types of cells and in a certain sequential manner. At the start of the production process, fresh medium (without animal components) is inoculated into the system and contains specific growth factors and small molecules. Multiple parameters of a cell culture bioreactor are carefully monitored and adjusted to maintain optimal levels of cell ...

Embodiment 2

[0239] Example 2: Cell Growth in Flexible Bags as Cell Culture Bioreactors of the Invention

[0240] Designed and produced a 2L aseptic bag. The bag consists of five layers of polyolefin-based An animal component-free membrane composition that provides excellent extractable and leachable profiles, water vapor and oxygen barrier, and fluid integrity (manufactured by Meissner Filtration Products, CA). The bag is sterilized by gamma radiation (25kGy-40kGy).

[0241] Proof-of-concept experiments were performed at a scale of 70 ml growth medium with a single plant-based scaffold with a volume of approximately 16.5 ml and a disposable bag as a cell culture bioreactor.

[0242] Use 325 x 10 in a growth medium volume of 25 ml 6Bovine fibroblasts and myoblasts were seeded into 70ml bags containing scaffolds. The headspace of the bag was filled with air and the bag was shaken at 2 cpm, placed at an angle of 10° at a temperature of 38.5°C. After one hour, an additional 45 ml of m...

Embodiment 3

[0245] Example 3: Growth of Two Cell Types on Scaffolds in a Cell Culture Bioreactor

[0246] Check for the presence of fibroblasts and myoblasts seeded on scaffolds at the end of the growth phase to ensure that the culture system can support growth of more than one cell type. Use PCR-assisted detection. Gene expression of the muscle progenitor marker Pax7 and the fibroblast marker collagen type 1 was tested. Scaffold samples (weight = 150 mg) from opposite ends of the scaffold were collected and homogenized and subjected to RNA extraction using the EZ RNA kit (Biological Industries, Israel). Bare scaffolds without cells were used as negative controls. Such as Image 6 As shown in , Pax7 and collagen type 1 were expressed at both ends of the seeded scaffold. As expected, these markers were not detected in samples obtained from bare scaffolds without cells. These data indicate that both bovine muscle progenitor cells and fibroblasts seeded on the scaffolds have adhered t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com