Anti-blocking discharging device for soap processing and production

A discharge device and anti-blocking technology, which is applied in transportation and packaging, dissolving, mixing machines, etc., can solve the problems of poor crushing effect of fillers and affecting the efficiency of soap processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

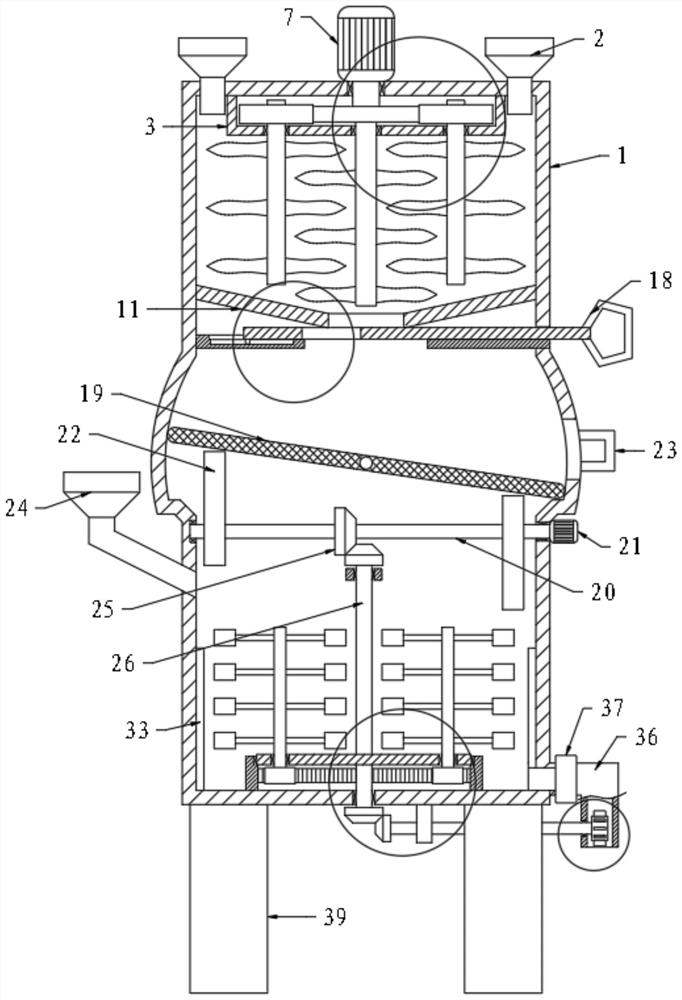

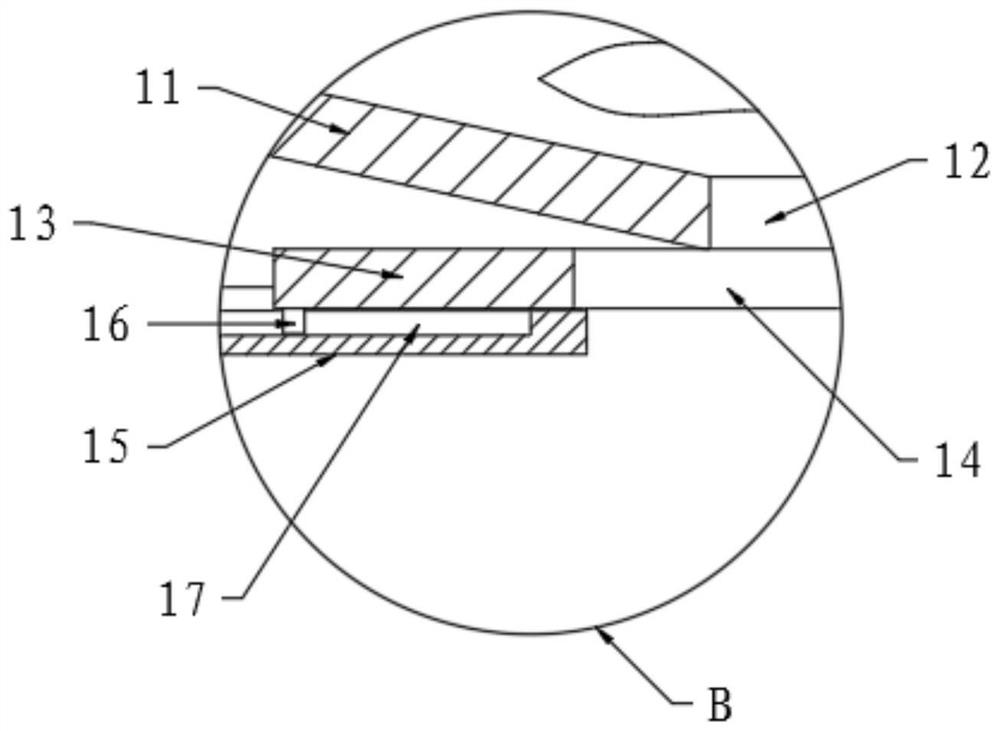

[0030] Please refer to the accompanying drawings, the present invention provides a technical solution: a kind of anti-blocking discharge device for soap processing production, comprising a processing box 1, the upper left and right sides of the processing box 1 are provided with feeding hoppers 2, the upper part of the processing box 1 There is also a crushing assembly and a blanking assembly. The middle part of the processing box 1 is provided with a filter assembly, and the bottom is provided with a stirring assembly. The right side of the bottom surface of the processing box 1 is also provided with a discharge pipe 36, and an electric valve is provided on the discharge pipe 36. 37. A number of supporting legs 39 are also provided on the bottom surface of the processing box 1.

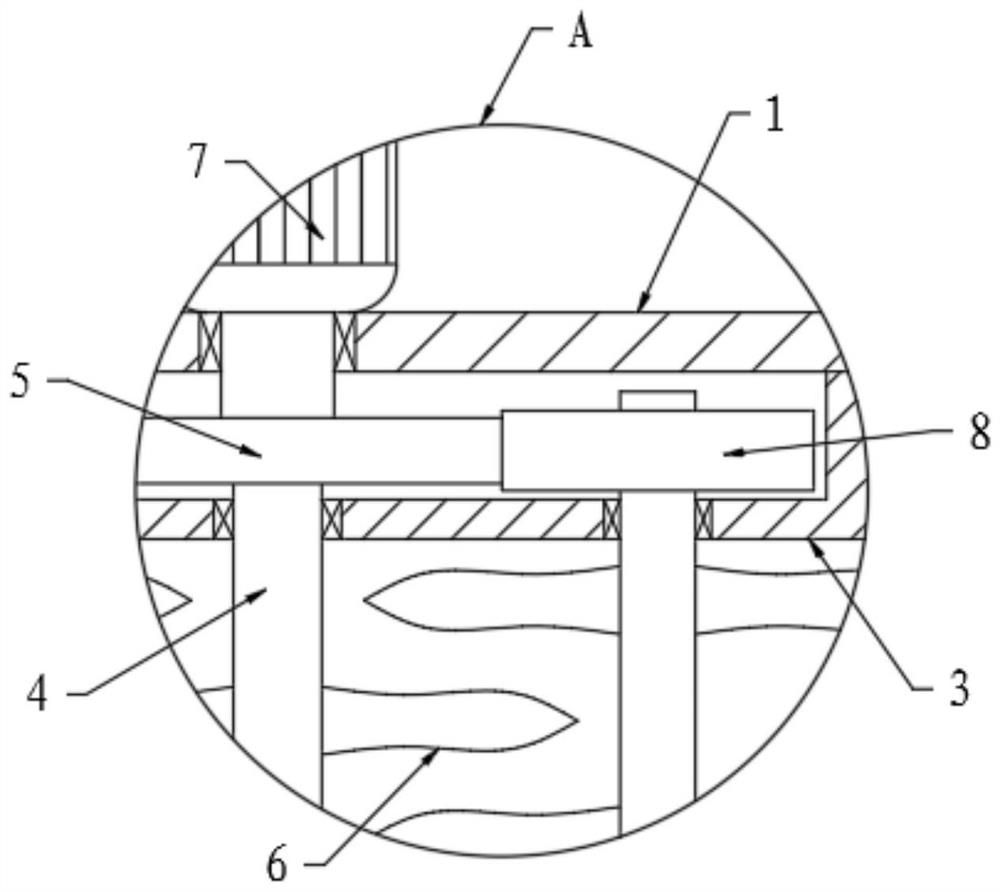

[0031] Wherein, the pulverizing assembly comprises No. 1 motor 7 that is fixedly connected on the top surface of the processing box 1, the driving end of the No. 1 motor 7 stretches into the processin...

Embodiment 2

[0040] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the stirring assembly includes a rotating shaft 26 that is rotatably connected to the bottom of the processing box 1, and a No. 1 bevel gear set is arranged between the top of the rotating shaft 26 and the drive rod 20 25 connected, the bottom of the rotating shaft 26 is coaxially fixed with a rotating plate 27, the outer side of the rotating plate 27 is rotatably connected with a fixed cover 28, the fixed cover 28 is fixed on the bottom surface of the processing box 1, and the left and right sides of the rotating plate 27 are rotatably connected There are two symmetrical stirring shafts 29, the top of the stirring shaft 29 is evenly provided with some stirring rods 30, the bottom of the stirring shaft 29 extends below the rotating plate 27, and is fixed with a rolling gear 31, fixed on the inner side wall of the fixed cover 28 There is an inner ring gear 32 meshing wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com