Nickel plating deep hole agent and preparation method and electroplating method thereof

A deep-hole agent and nickel-plating technology, applied in the field of nickel-plating deep-hole agent and its preparation, can solve the problems of coating rust, product failure, poor consistency of inner cavity coating, etc., achieve fine crystallization, meet anti-corrosion requirements, and improve adsorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

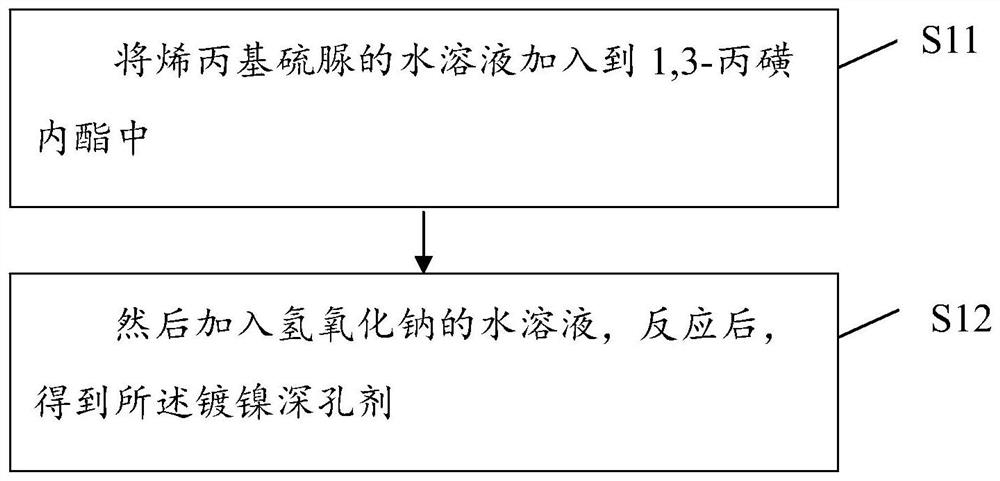

[0057] Preparation of nickel plating deep hole agent:

[0058] Under stirring conditions, according to the mass ratio of allylthiourea and 1,3-propanesultone of 2:1, add the aqueous solution of allylthiourea with a mass fraction of 10% to 1,3-propanesulfone In the lactone, then adding an aqueous solution of 5% sodium hydroxide to adjust the pH of the system to 7, reacting at 50°C, washing the obtained solid reaction product twice with water, and drying to obtain the nickel-plated deep Pore agent (sodium allylthiourea propane sulfonate).

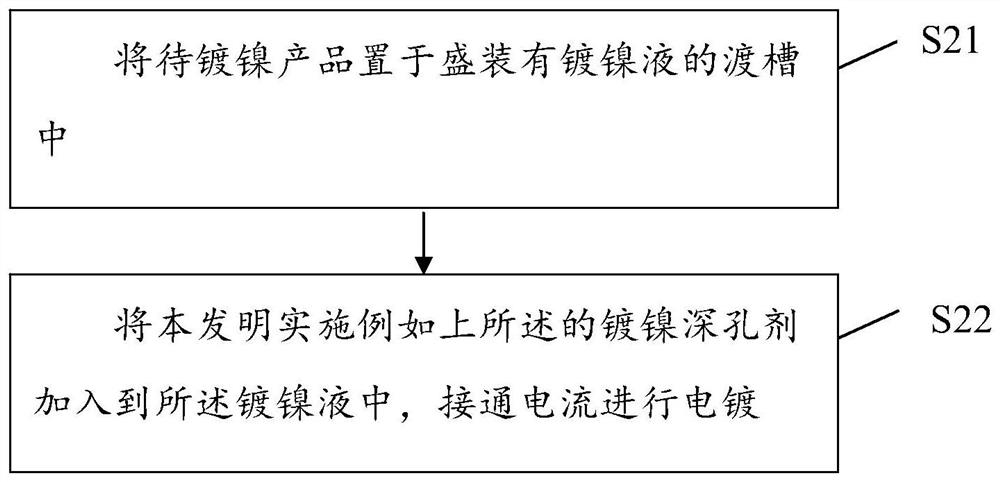

[0059] Configuration of nickel plating solution:

[0060] Fully mix nickel sulfate, nickel chloride, boric acid, main light agent, softener, positioning agent and pure water so that the concentration of nickel sulfate in the nickel plating solution is 200g / L, and the concentration of nickel chloride is 50g / L , The concentration of boric acid is 50g / L, the concentration of the main light agent is 0.4g / L, the concentration of the softener i...

Embodiment 2

[0067] Preparation of nickel plating deep hole agent:

[0068] Under stirring conditions, according to the mass ratio of allylthiourea and 1,3-propanesultone of 2:1, add the aqueous solution of allylthiourea with a mass fraction of 10% to 1,3-propanesulfone In the lactone, then adding an aqueous solution of 5% sodium hydroxide to adjust the pH of the system to 7, reacting at 50°C, washing the obtained solid reaction product twice with water, and drying to obtain the nickel-plated deep Pore agent (sodium allylthiourea propane sulfonate).

[0069] Configuration of nickel plating solution:

[0070] Fully mix nickel sulfate, nickel chloride, boric acid, main light agent, softener, positioning agent and pure water so that the concentration of nickel sulfate in the nickel plating solution is 220g / L, and the concentration of nickel chloride is 55g / L , The concentration of boric acid is 55g / L, the concentration of main light agent is 0.5g / L, the concentration of softener is 10g / L,...

Embodiment 3

[0077] Preparation of nickel plating deep hole agent:

[0078] Under stirring conditions, according to the mass ratio of allylthiourea and 1,3-propanesultone of 2:1, add the aqueous solution of allylthiourea with a mass fraction of 10% into 1,3-propanesultone In the ester, then add an aqueous solution of sodium hydroxide with a mass fraction of 5% to adjust the pH of the system to 7. After the reaction at 50°C, the solid reaction product obtained is washed twice with water, and the nickel-plated deep hole is obtained after drying. agent (sodium allylthiourea propane sulfonate).

[0079] Configuration of nickel plating solution:

[0080] Fully mix nickel sulfate, nickel chloride, boric acid, main light agent, softener, positioning agent and pure water so that the concentration of nickel sulfate in the nickel plating solution is 210g / L, and the concentration of nickel chloride is 53g / L , The concentration of boric acid is 53g / L, the concentration of main light agent is 0.45g / L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com