Metal organic framework derived nitrogen-doped carbon nanosheet as well as preparation method and application thereof

A metal-organic framework, nitrogen-doped carbon technology, applied in the field of inorganic non-metallic materials and electrochemistry, can solve the problems of cathode electrochemical kinetic loss, slow oxygen reduction reaction, lower reaction energy barrier, etc., and achieve good scalability , the effect of simple operation and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1), 30 ml of DMF poured into the beaker, add 30 mg of ammonia acetic acid, add 450 mg of nitrate, 300 mg of terephthalic acid added to DMF solution, continued 40 min, then transfer solution transfer Between 50 ml of the reactor;

[0040] (3), place the reactor containing a solution in an oven, and the heat reaction is carried out 90 ° C, 15 hours;

[0041] (4), the sample after the solvent was hot, and the light pink precipitate was obtained by centrifugation, and the precipitate was placed in an oven at 60 ° C, drying for 24 hours;

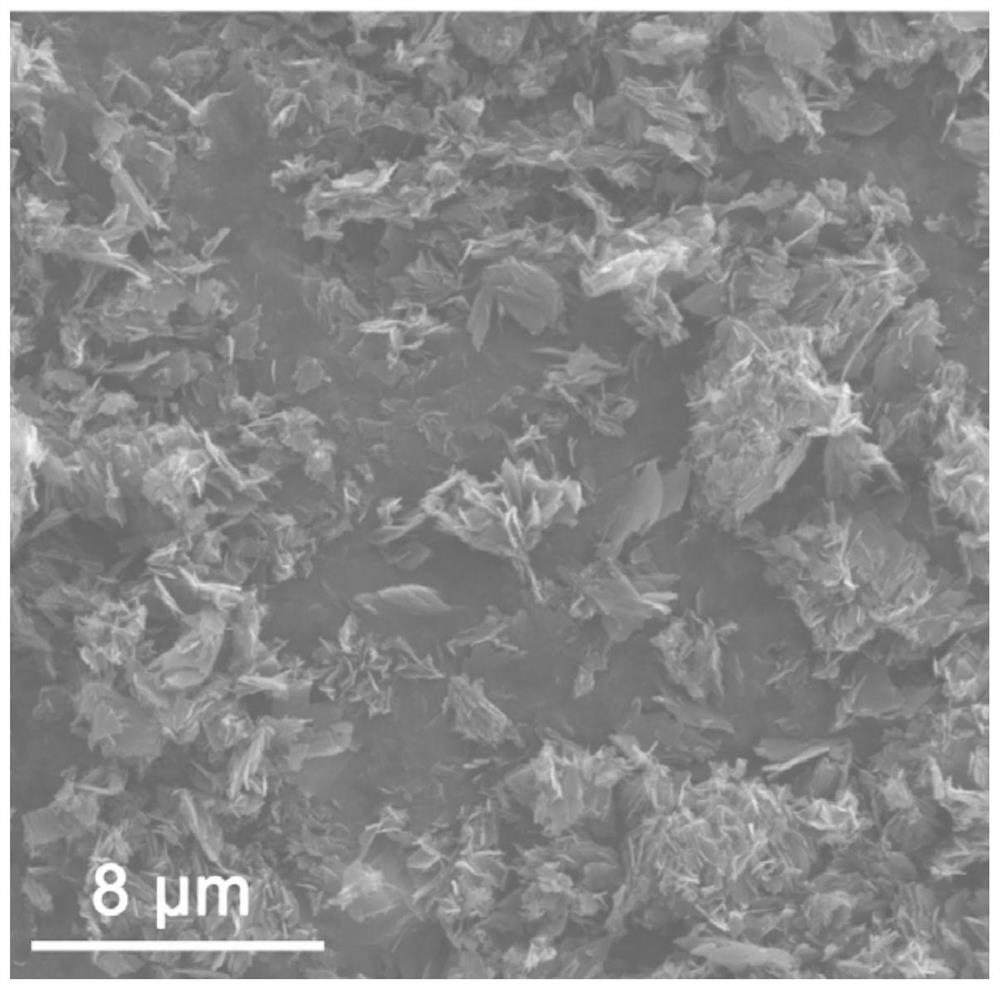

[0042] (5) After the dried light pink powder is dispersed, it is placed in the ceramic boat, and the porcelain boat is placed in the tube furnace. After 20 minutes of high purity nitrogen, the temperature is warmed to 1000 ° C, the temperature rise rate is 10 ° C. / min, heat insulation for 2 hours, naturally cooled to room temperature, to obtain a dark black nitrogen dopilateral; specific surface area is 600 cm -2 G -1 The average aperture s...

Embodiment 2

[0046](1), 40 ml of DMF was poured into the beaker, and 200 mg of ammonia acetic acid was added, adding 1000 mg of nitric nitrate and 1000 mg of an amino group added to DMF solution, continued 40 min, then the solution Transfer to 50 mL of the reactor;

[0047] (3), place the reactor containing a solution in an oven, and the solvent is thermally reacted 120 ° C, 6 hours;

[0048] (4), the sample after the solvent was hot, and the light pink precipitate was obtained by centrifugation, and the precipitate was placed in an oven at 60 ° C, drying for 24 hours;

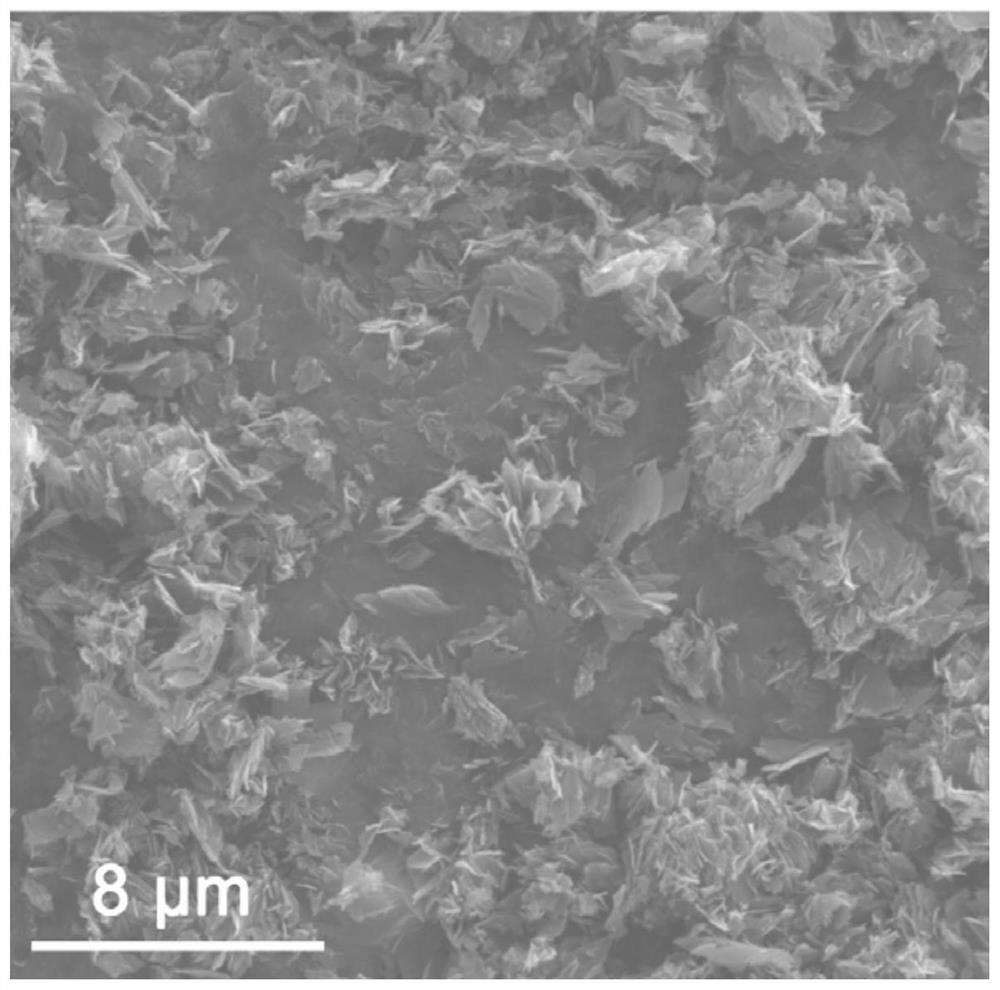

[0049] (5) After the dried light pink powder is dispersed, it is placed in a ceramic boat, and the porcelain boat is placed in the tube furnace. After 20 minutes of high purity nitrogen, the temperature is increased to 800 ° C, the temperature rise rate is 5 ° C. / min, heat insulation 10 hours, naturally cooled to room temperature, to obtain a dark black nitrogen dopilateral; the specific surface area is 800 cm -2 G -1 The av...

Embodiment 3

[0053] (1) Pour 50 ml of DMF into the beaker, 500 mg of ammonia water, add 1500 mg of nitrate and 1500 mg of amino group terephthalic acid to add to the DMF solution, continued 40 min, then transfer the solution to the solution 50 ml of the reactor;

[0054] (3), place the reactor containing a solution in an oven, and the solvent is thermally reacted 150 ° C, 8 hours;

[0055] (4), the sample after the solvent was hot, and the light pink precipitate was obtained by centrifugation, and the precipitate was placed in an oven at 60 ° C, drying for 24 hours;

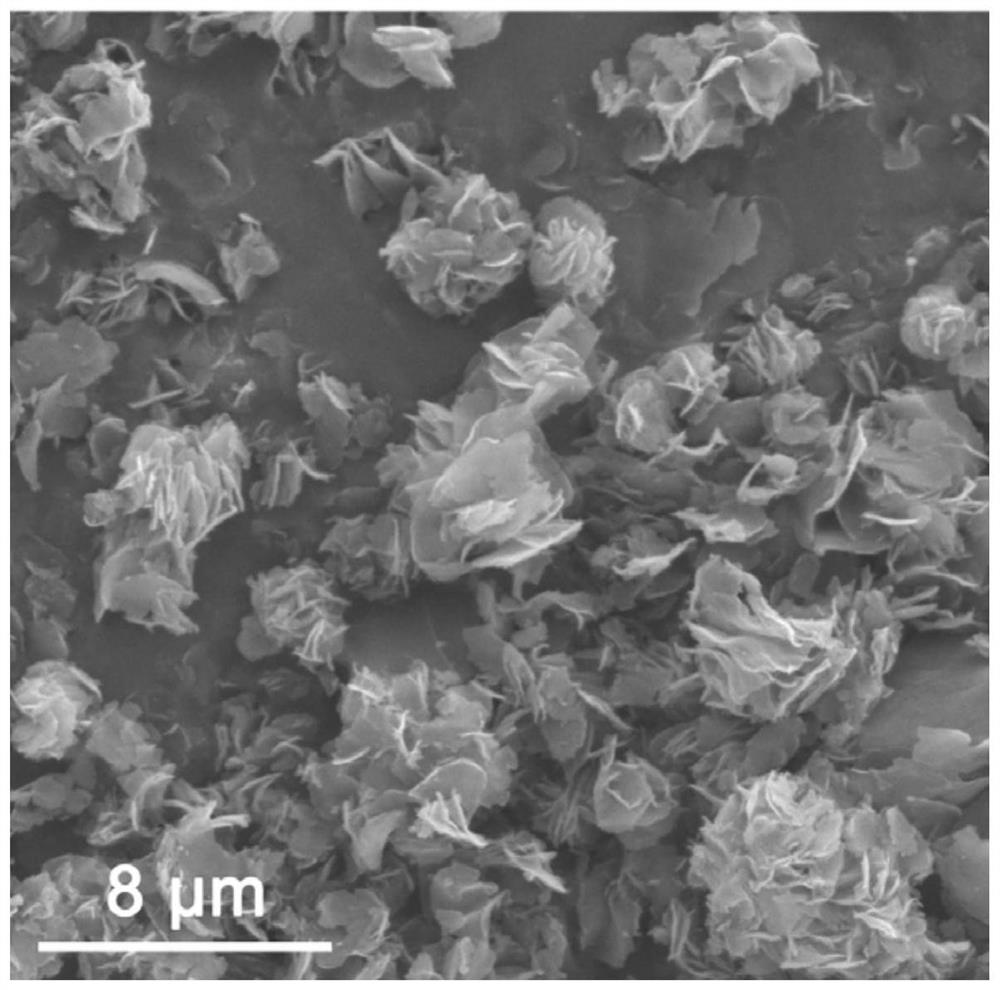

[0056] (5) After the dried light pink powder is dispersed, it is placed in a ceramic boat, and the porcelain boat is placed in the tube furnace. After 20 minutes of high purity nitrogen, the temperature is increased to 1000 ° C, the temperature rise rate is 2 ° C. / min, heat insulation for 4 hours, naturally cooled to room temperature, to obtain a dark black nitrogen doped nanoflake; specific surface area is 1500 cm -2 G -1 The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com