Method for preparing pore gradient self-cleaning water permeable brick from coal gangue ceramsite

A technology of coal gangue ceramsite and permeable bricks, which is applied in the production of ceramic products, clay products, ceramic materials, etc., can solve problems such as insufficient technology

Active Publication Date: 2022-03-25

PINGXIANG UNIV

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

There are relatively few manufacturers producing gangue-type permeable bricks, and the technology is not perfect enough

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0042] In order to make the objects and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

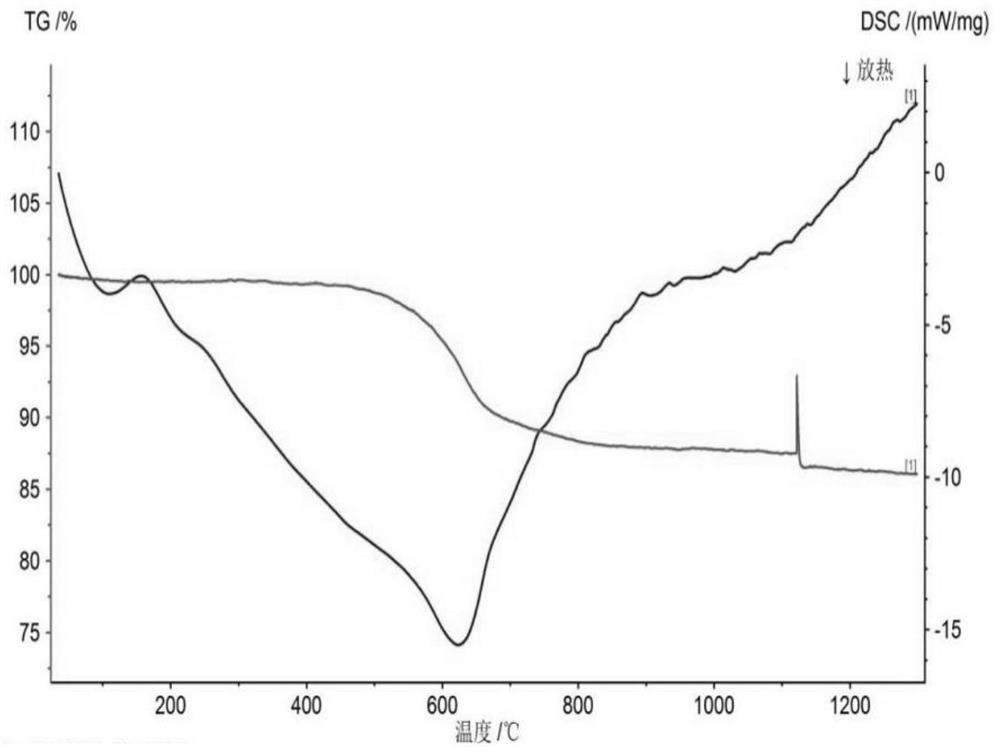

The invention relates to the field of preparation of coal gangue water permeable bricks, in particular to a method for preparing a pore gradient self-cleaning water permeable brick from coal gangue ceramsite. Coal gangue is used as a main raw material, low-temperature glass frit powder is used as a binder, oxides such as zinc oxide are used as photocatalysts, and sodium carboxymethyl cellulose with the concentration of 0.2% is used as a pelletizing auxiliary agent to prepare the coal gangue ceramsite water permeable brick. Wherein the adding amount of the low-temperature glass frit powder is 5%, the sintering temperature is 1250 DEG C, and the heat preservation time is 30 min. The water permeable brick obtained by the invention is relatively good in performance, the water absorption rate is 8.79%, the compressive strength is 4.22 MPa, the porosity is 12.38%, and the water permeability coefficient is 2.33 * 10 <-2 >.

Description

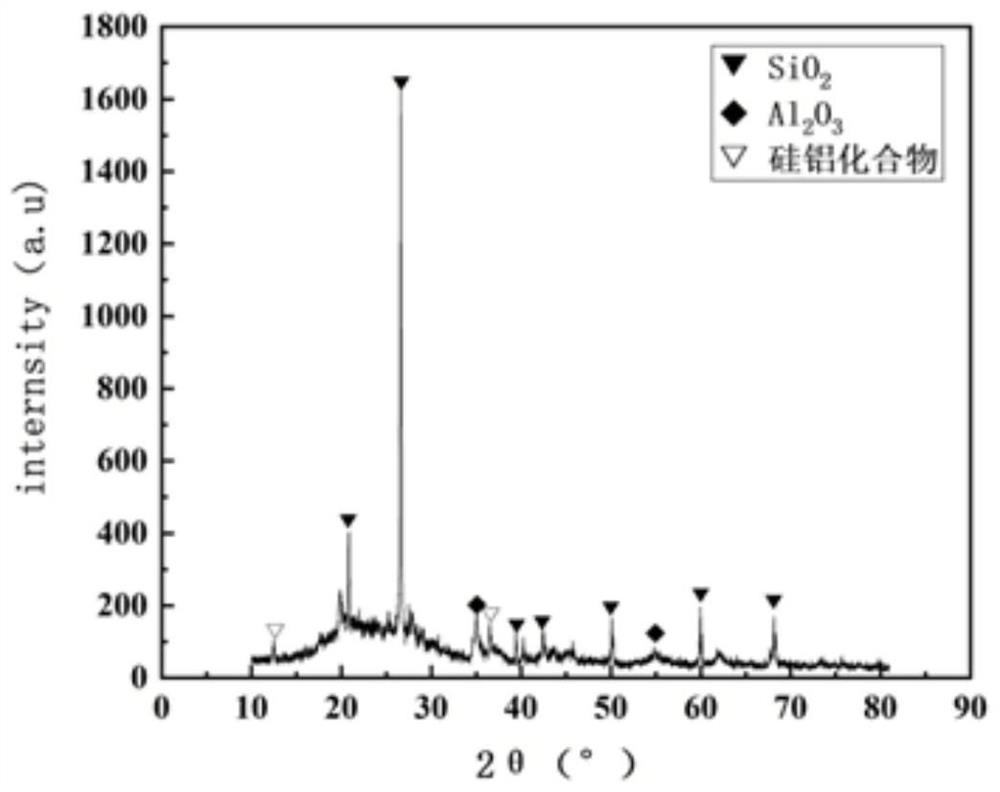

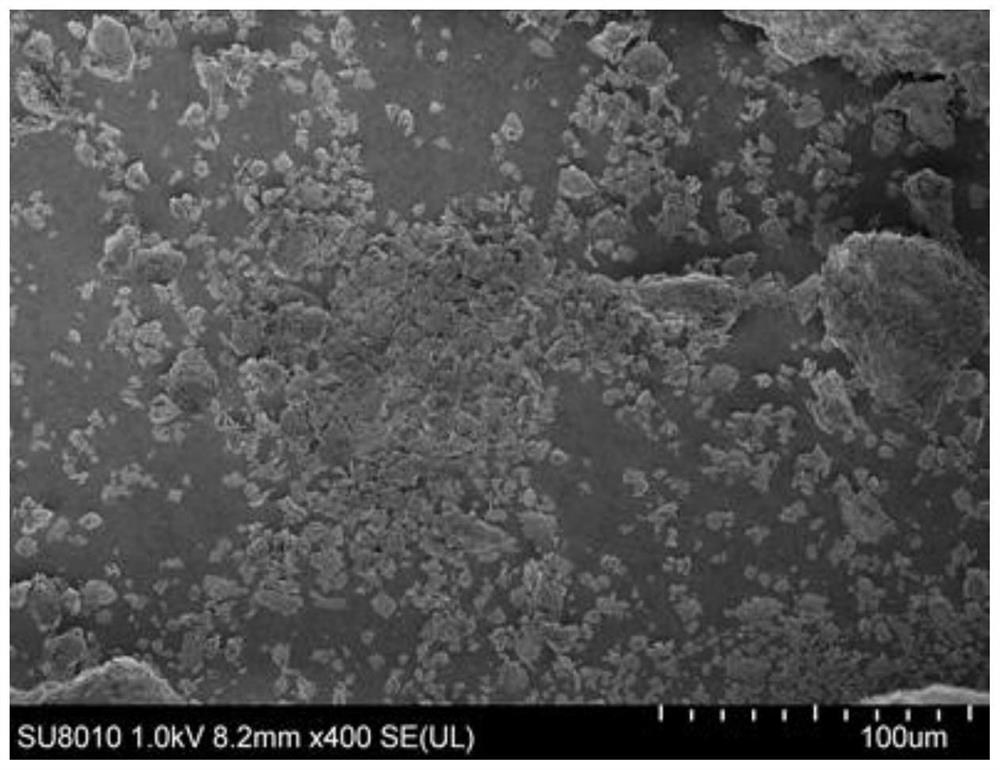

technical field [0001] The invention relates to the field of preparation of coal gangue permeable bricks, in particular to a method for preparing pore gradient self-cleaning permeable bricks from coal gangue ceramsite. Background technique [0002] Coal mining and processing will produce a large amount of solid waste—coal gangue, which is one of the industrial solid wastes with the largest annual discharge and cumulative accumulation in my country. Its main component is Al 2 o 3 , SiO 2 , also contains a certain amount of Fe 2 o 3 , CaO, MgO, Na 2 O, K 2 O.P 2 o 5 , SO 3 And trace rare elements (gallium, vanadium, titanium, cobalt, etc.), these components determine its broad application prospects in the building materials industry. The utilization of coal gangue in the market mainly includes: ① recovery of coal and pyrite, ② use in power generation, ③ manufacture of building materials, ④ bio-fertilizer. [0003] At present, coal gangue is mainly used in the product...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B38/06C04B33/132C04B33/13

CPCC04B38/0645C04B33/132C04B33/131C04B33/13C04B2235/36C04B2235/6567C04B2235/96C04B38/0074Y02P40/60

Inventor 宋杰光庞才良杨雪晴向芸

Owner PINGXIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com