Catalytic synthesis method of propanil

A synthesis method, the technology of propanil, which is applied in the field of synthesis of propanil, achieves the effects of low production cost, simple process and simple post-treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

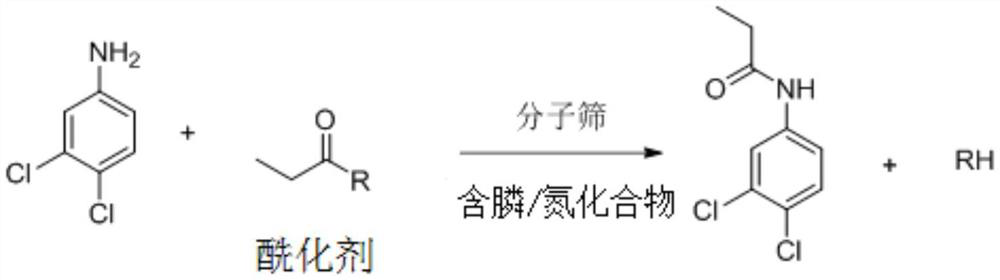

Method used

Image

Examples

Embodiment 1

[0026] Add 164.42g of 3,4-dichloroaniline (purity 98.5%, 1mol), 133.23g of propionic anhydride, 0.16g of molecular sieve, 0.16g of phosphine / nitrogen compound into a 500mL four-neck flask, then slowly raise the temperature to 145-155°C, Reflux and keep warm for 3-4h. After the reaction, the generated propionic acid is distilled off, and then the molecular sieve is recovered by filtration, and then the remaining raffinate is cooled and stirred for crystallization, and then dried after the crystallization is complete to obtain the propanil product.

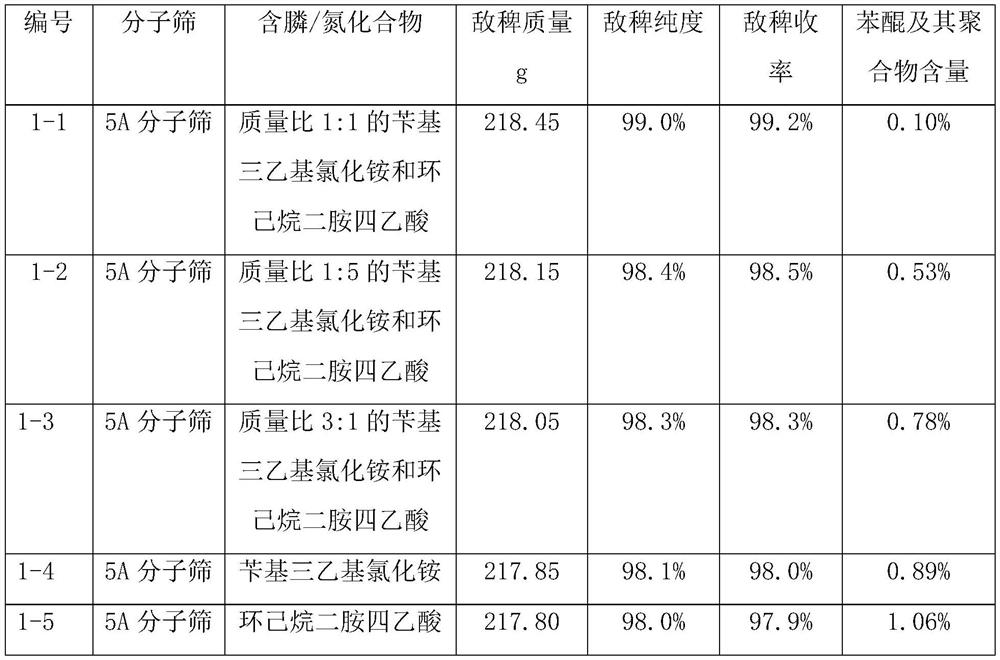

[0027] According to the above method, different molecular sieves and phosphine / nitrogen-containing compounds were used to synthesize propanil, and the results are shown in Table 1 below:

[0028] Table 1

[0029]

[0030]

[0031]

Embodiment 2

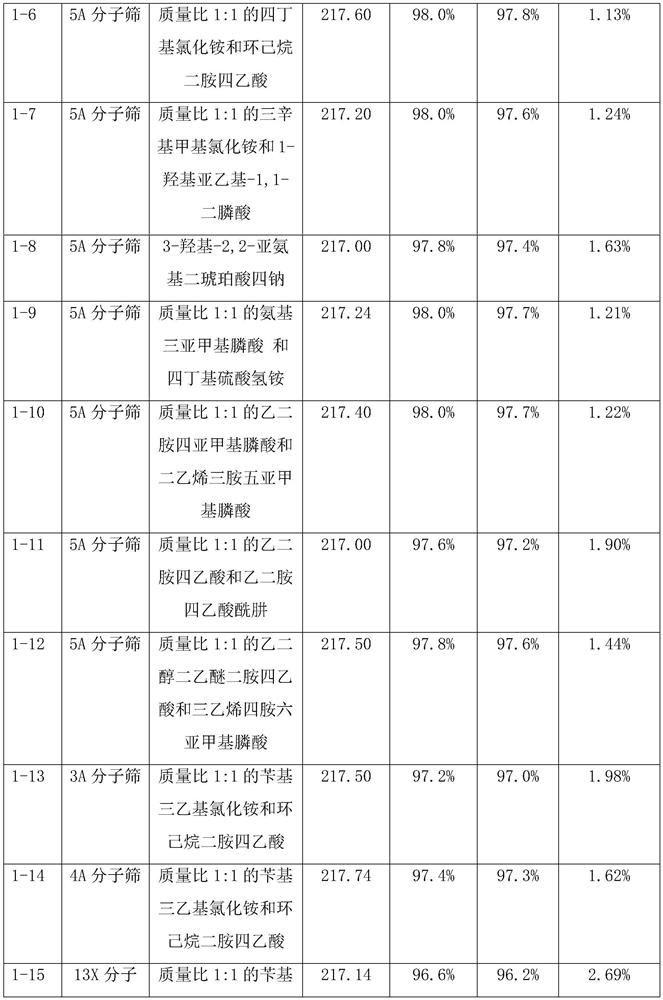

[0033] Add 164.39g 3,4-dichloroaniline (purity 98.5%, 1mol) in 500mL four-necked flask, 133.23g propionic anhydride, molecular sieve 5A of different quality, the phosphine / nitrogen compound of different quality (mass ratio 1:1 Cyclohexanediaminetetraacetic acid and benzyltriethylammonium chloride), slowly warm up to the reflux temperature of 145-155°C, and keep the reaction under reflux for 3-4h. After the reaction, the generated propionic acid is distilled off, and then the molecular sieve is recovered by filtration, and then the remaining raffinate is cooled and stirred for crystallization, and then dried after the crystallization is complete to obtain the propanil product.

[0034] The amount of molecular sieves and phosphine / nitrogen-containing compounds and the product situation are shown in Table 2 below:

[0035] Table 2

[0036]

[0037]

Embodiment 3

[0039] In a 500mL four-necked flask, add 164.39g 3,4-dichloroaniline (purity 98.5%, 1mol), different quality acylating agents, 0.16g molecular sieve 5A, 0.16g different phosphine / nitrogen compounds, slowly rise to Different temperature, insulation reaction 3-4h. After the reaction, the generated by-products are removed by distillation, and then the molecular sieves are recovered by filtration, and then the remaining raffinate is cooled and stirred for crystallization, and dried after the crystallization is complete to obtain the propanil product.

[0040] The situation of the propanil product obtained under different reaction conditions is shown in Table 3 below:

[0041] table 3

[0042]

[0043]

[0044] Note: The amount of acylating agent refers to the molar ratio of acylating agent to 3,4-dichloroaniline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com