Production process and application of T4P state aluminum alloy narrow coiled plate

A production process and aluminum alloy technology, which is applied in the field of metal plastic processing, can solve problems such as cracking of layered composite materials, high operation difficulty, deformation performance, etc., achieve uniform structure and performance, avoid operation difficulty, and improve the yield of finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment provides a kind of T4P state aluminum alloy narrow roll plate production process, which is used for hot-rolling composite production of strip method with a thickness ratio of 0.7 / 8.6 / 0.7 316 stainless steel / 6013 aluminum alloy / 316 stainless steel three-layer composite plate, the width of which is is 160mm. Among them, the 6013 aluminum alloy sheet is a narrow coil sheet with a thickness of 18mm and a width of 160mm.

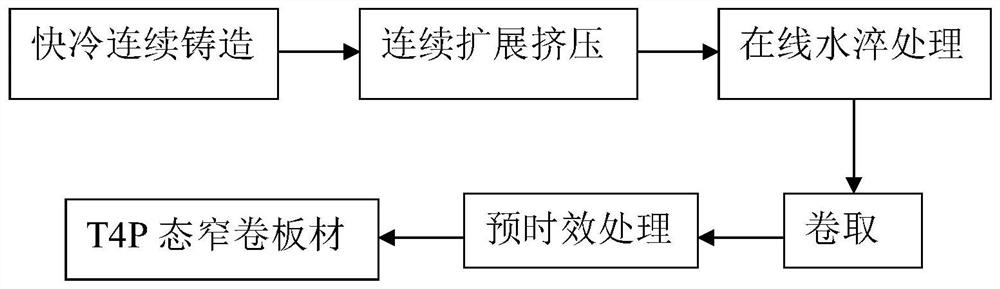

[0051] The production process of the narrow roll plate is as follows:

[0052] (1) Rapid cooling continuous casting: use 99.7% aluminum ingots, instant Si, magnesium ingots and Al-Mn, Al-Cr, Al-Cu master alloys, calculate the weight ratio of each alloy added according to the chemical composition range of 6013 aluminum alloy, According to this proportion, after melting, refining, heat preservation and on-line filtration in a 5000Kg capacity gas melting furnace, a wheel-type continuous casting machine with a diameter of 1800mm is continuousl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com