Negative current collector of sodium ion battery, preparation method of negative current collector and sodium ion battery

A technology for sodium ion batteries and current collectors, applied in the direction of electrode carriers/current collectors, battery electrodes, negative electrodes, etc., can solve the problems of reducing local current density, low cycle efficiency of sodium ion batteries, and growth of sodium dendrites, etc. Local current density, inhibited growth, effect of promoting uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

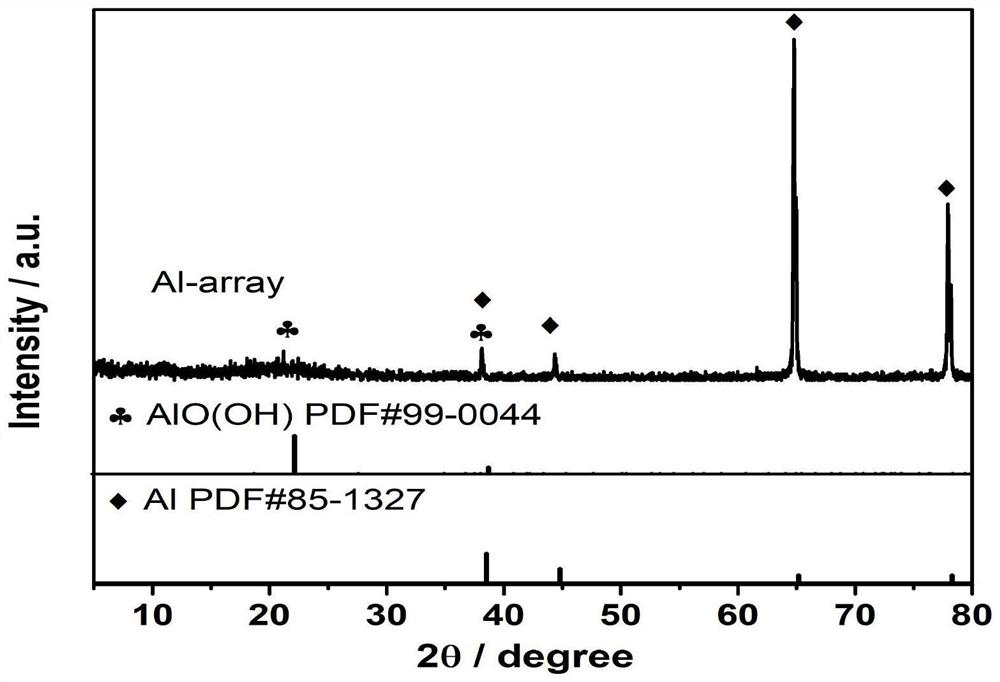

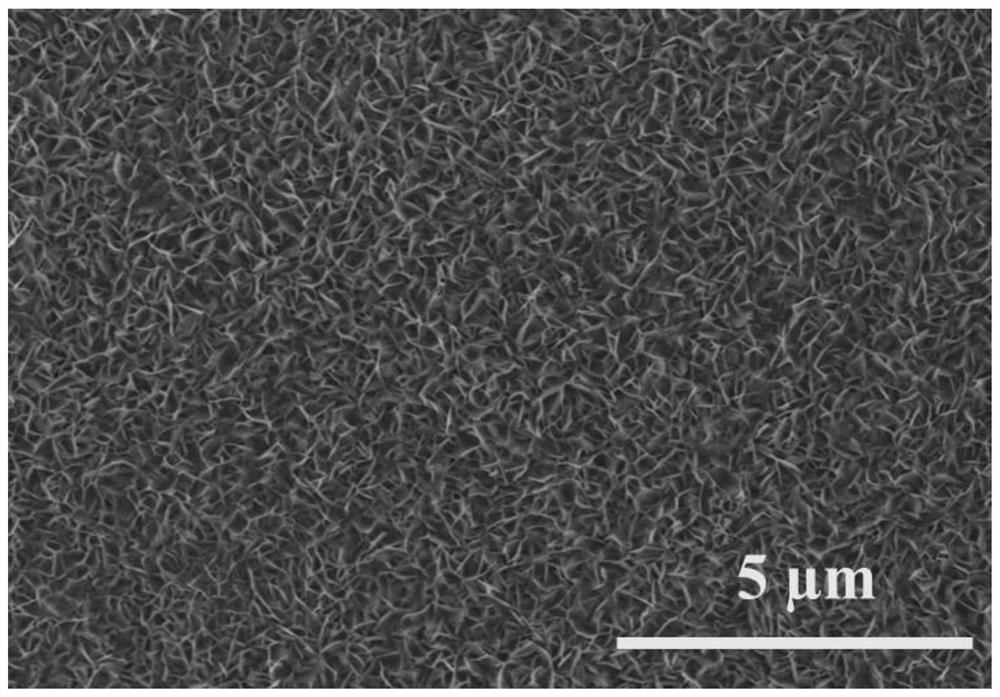

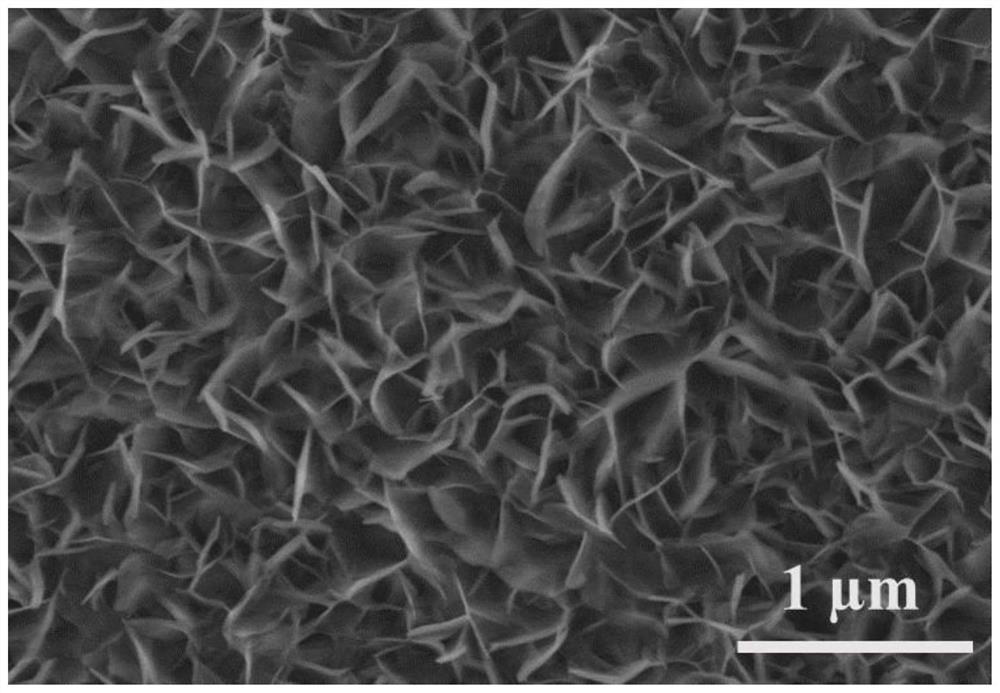

[0034] This embodiment 1 provides the first preparation method of the negative electrode collector of the sodium ion battery, including the following steps: accurately weigh 0.01mmol potassium hydroxide, add it to 10mL glycerol, and stir it magnetically at a speed of 500r / min for 1 hours, take 50 μL of the solution and drop it on an aluminum foil with a diameter of 12 mm, react at 25°C for 8 hours, wash the surface of the aluminum foil three times alternately with deionized water and absolute ethanol, and dry it at 25°C to obtain a negative electrode for a sodium-ion battery current collector.

Embodiment 2

[0036] This embodiment 2 provides the second preparation method of the negative electrode current collector of the sodium ion battery, which includes the following steps: accurately weigh 0.01 mmol of nickel hydroxide, add it to 10 mL of ethylenediamine, and stir it magnetically for 5 at a speed of 200 r / min. hour, take 50 μL of the solution and drop it on an aluminum foil with a diameter of 12 mm, react at 80°C for 4 hours, wash the surface of the aluminum foil with deionized water and absolute ethanol alternately for 3 times, and dry it at 80°C to obtain the negative electrode of the sodium ion battery current collector.

Embodiment 3

[0038] This embodiment 3 provides the third preparation method of the negative electrode current collector of the sodium ion battery, which includes the following steps: accurately weigh 0.2mmol calcium hydroxide, add it to 10mL glycerol, and stir it magnetically for 5 minutes at a speed of 1000r / min. hour, take 200 μL of the solution and drop it on an aluminum foil with a diameter of 12 mm, react at 60°C for 5 hours, wash the surface of the aluminum foil with deionized water and absolute ethanol alternately for 3 times, and dry it at 50°C to obtain the negative electrode of the sodium ion battery current collector.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com