Cu3P@P-doped mesoporous carbon composite framework, and preparation method and application thereof

A mesoporous carbon skeleton and mesoporous carbon technology, applied in the direction of electrode carriers/current collectors, active material electrodes, electrical components, etc., can solve the problems of low Coulombic efficiency, uncontrollable dendrites, large volume effect, etc., and achieve accelerated transmission , reduce negative effects, and accelerate the effect of catalytic conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

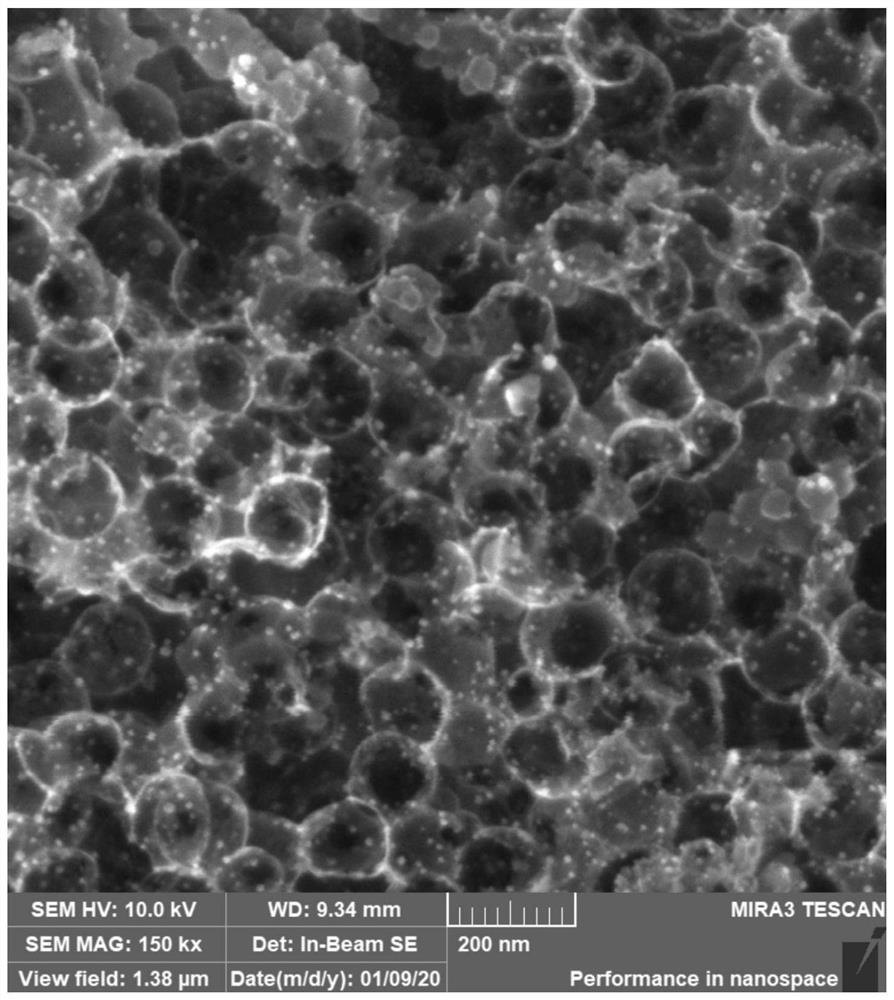

[0065] SiO with an average particle size of 200 nm 2 The balls were prepared into a 10g / L sol, stirred evenly at 50°C, then added cassava flour, and stirred vigorously. Cassava flour, SiO 2 The weight ratio is 50:40. Stir for 3h and dry for 12h. Transfer to a tube furnace under argon flow, heat up to 1000°C at a rate of 5°C / min and roast for 3 hours, after cooling down, place in 5M NaOH solution and stir for 12 hours, filter and wash, and dry at 80°C for 8 hours to prepare mesoporous carbon.

[0066] Get the mesoporous carbon that 0.5g above-mentioned steps prepares (specific surface area is 500m 2 / g, the carbon wall thickness is 30nm, and the chamber volume ratio is 70%) in 100ml of copper acetate ethanol solution with a concentration of 10g / L, magnetically stirred at 25°C for 12h, filtered, cleaned, and dried, in a tube furnace Under an argon atmosphere, the temperature was raised to 800 °C for 3 h at a rate of 5 °C / min to obtain CuO nanoparticles@mesoporous carbon.

...

Embodiment 2

[0071] SiO with an average particle size of 300 nm 2 The balls were formulated into 15g / L sol, stirred evenly at 50°C, then added sucrose, and stirred. Sucrose, SiO 2 The weight ratio is 55:45. The stirring time is 3h, and the drying time is 12h. Transfer to a tube furnace and heat up to 9000°C for 5 hours at a rate of 8°C / min under argon flow, then place in 6M NaOH solution and stir for 24 hours after cooling down, filter and wash, and dry at 80°C for 8 hours to prepare mesoporous carbon.

[0072] Get the mesoporous carbon that 0.5g above-mentioned steps prepares (specific surface area is 610m 2 / g, the carbon wall thickness is 25nm, and the chamber volume ratio is 75%) in 100ml of copper nitrate propanol solution with a concentration of 30g / L, magnetically stirred at 25°C for 8h, filtered, cleaned, dried, and dried in a tube furnace Under argon atmosphere, the temperature was raised to 900°C at a rate of 510°C / min and calcined for 2.5h to obtain Cu nanoparticles@mesoporo...

Embodiment 3

[0076] SiO with an average particle size of 300 nm 2 The balls were prepared into 10g / L sol, stirred at 50°C, and then starch was added and stirred. Starch, SiO 2 The weight ratio is 50:40. Stir for 3h and dry for 12h. Transfer to a tube furnace and heat up at 3°C / min to 1200°C for 2h under an argon flow. After cooling down, stir in 8M NaOH solution for 12h, filter and wash, and dry at 80°C for 8h to prepare mesoporous carbon.

[0077] Get the mesoporous carbon that 0.5g above-mentioned steps prepares (specific surface area is 600m 2 / g, the carbon wall thickness is 26nm, and the chamber volume ratio is 73%) in 100ml of copper acetate ethanol solution with a concentration of 40g / L, magnetically stirred at 30°C for 18h, filtered, cleaned, and dried, in a tube furnace Under an argon atmosphere, the temperature was raised from 5°C / min to 1000°C for 5h to obtain Cu nanoparticles@mesoporous carbon.

[0078] Take 3g of sodium metaphosphate and place it in the upper airflow dire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com