Three-dimensional composite potassium metal negative electrode and preparation method and application thereof

A three-dimensional composite and metal negative electrode technology, applied in the direction of negative electrodes, battery electrodes, active material electrodes, etc., can solve the problem that it is difficult to obtain high stability and high safety composite potassium metal negative electrodes, which hinders the large-scale application of metal potassium negative electrodes, and cannot achieve suppression Dendrite growth and other problems, to achieve the effect of easy operation of the preparation method, reduction of local current density, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

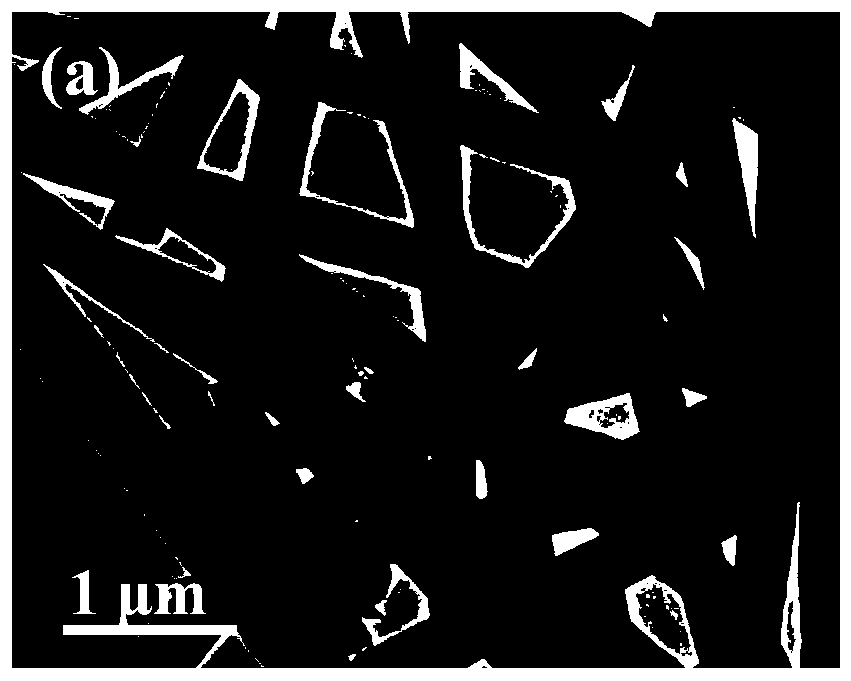

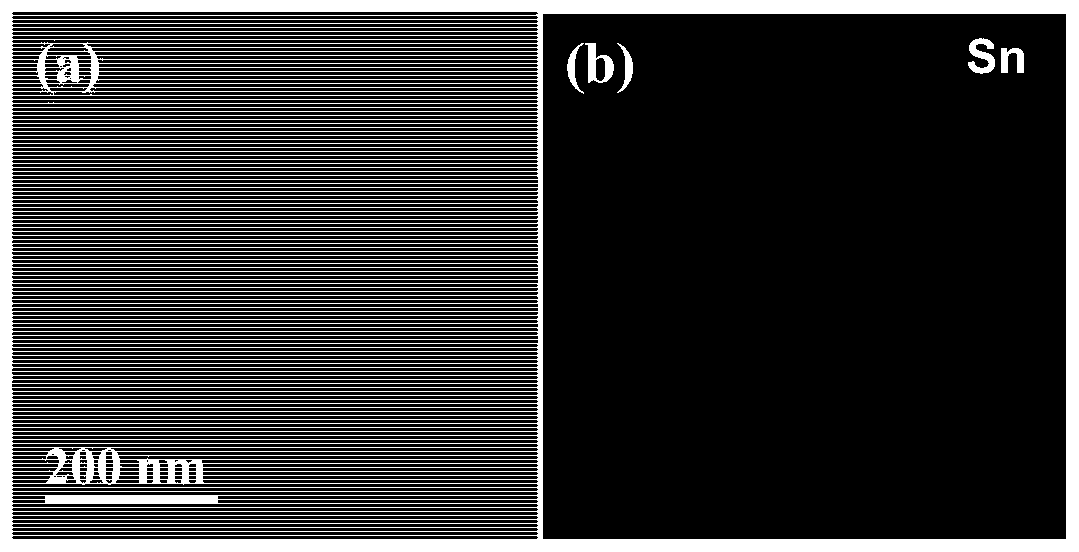

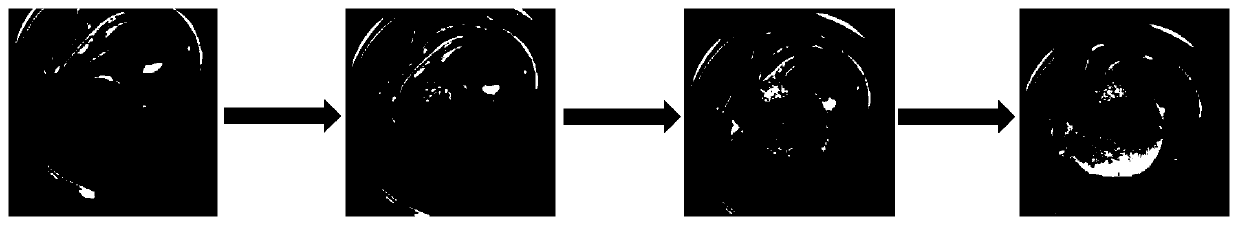

[0026] Example 1: Microporous carbon nanofibers are prepared by electrospinning technology, configure 8wt.% polyacrylonitrile N,N-dimethylformamide solution, set the electrospinning parameter voltage to 14KV, the distance between the injector and the collector The distance was 15cm, the solution flow rate was 0.6mL / h, and the polyacrylonitrile precursor film was prepared after four hours. The polyacrylonitrile film was placed in a tube furnace, pretreated at 280°C for 3 hours in an air atmosphere, and then carbonized at 600°C for 2 hours in an inert atmosphere of nitrogen to prepare a microporous carbon nanofiber film. Then the microporous carbon nanofibers were placed in the cavity of the atomic layer deposition equipment, with (dimethylamino) tin as the precursor, the flow rate of the carrier gas nitrogen was 40 sccm, the temperature was set at 170 ° C, and the reaction time was 2 h. where SnO 2 Evenly wrapped on the surface of carbon nanofibers. The SnO 2 / PCNF composite...

Embodiment 2

[0027] Embodiment 2: The difference between embodiment 2 and embodiment 1 is that the fiber film stabilized in the air atmosphere is calcined at 800° C. in a high-temperature inert atmosphere to prepare microporous carbon nanofibers; the reaction time of atomic layer deposition is 5h, and other The parameters remain the same. where SnO 2 uniformly wrapped on the surface of carbon nanofibers. The SnO 2 / PCNF composites can directly absorb hot-melt metal potassium to obtain a three-dimensional composite potassium metal anode.

Embodiment 3

[0028] Embodiment 3: The difference between embodiment 3 and embodiment 1 is that the fiber film stabilized in the air atmosphere is calcined at 1000 ° C in a high temperature inert atmosphere to prepare microporous carbon nanofibers; the reaction time of atomic layer deposition is 8h, and other The parameters remain the same. where SnO 2 uniformly wrapped on the surface of carbon nanofibers. The SnO 2 / PCNF composites can directly absorb hot-melt metal potassium to obtain a three-dimensional composite potassium metal anode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com