Method for preparing silica sol with large particle size and narrow distribution

A narrow distribution, silica sol technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve problems such as difficulty in meeting CMP requirements, small particle size, and wide particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

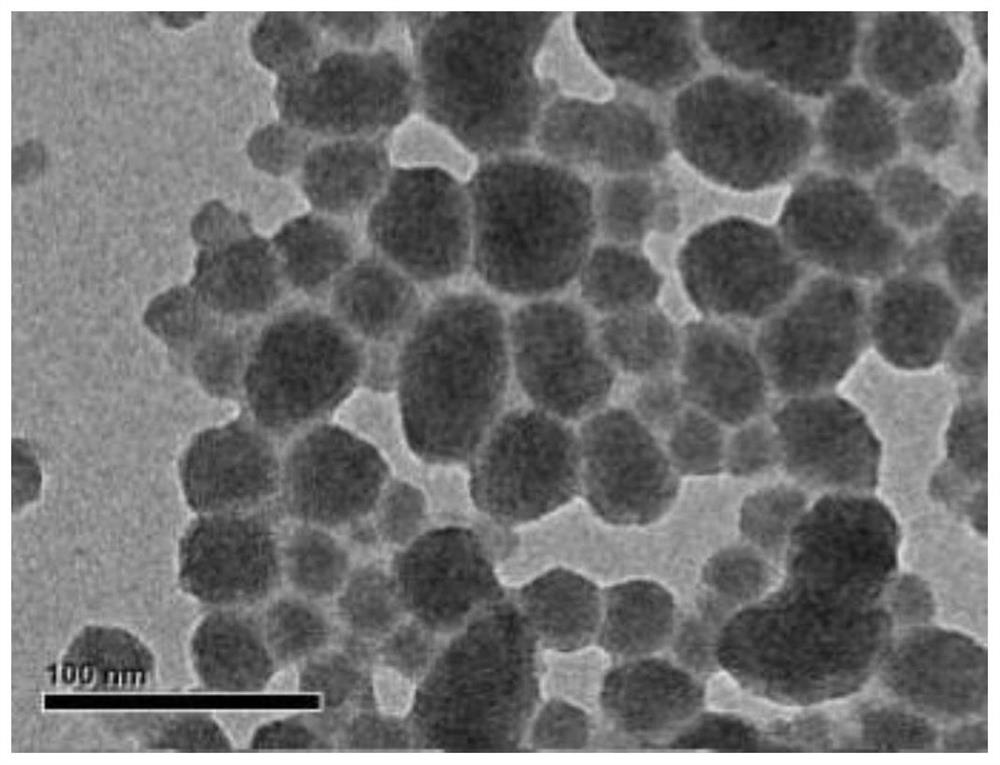

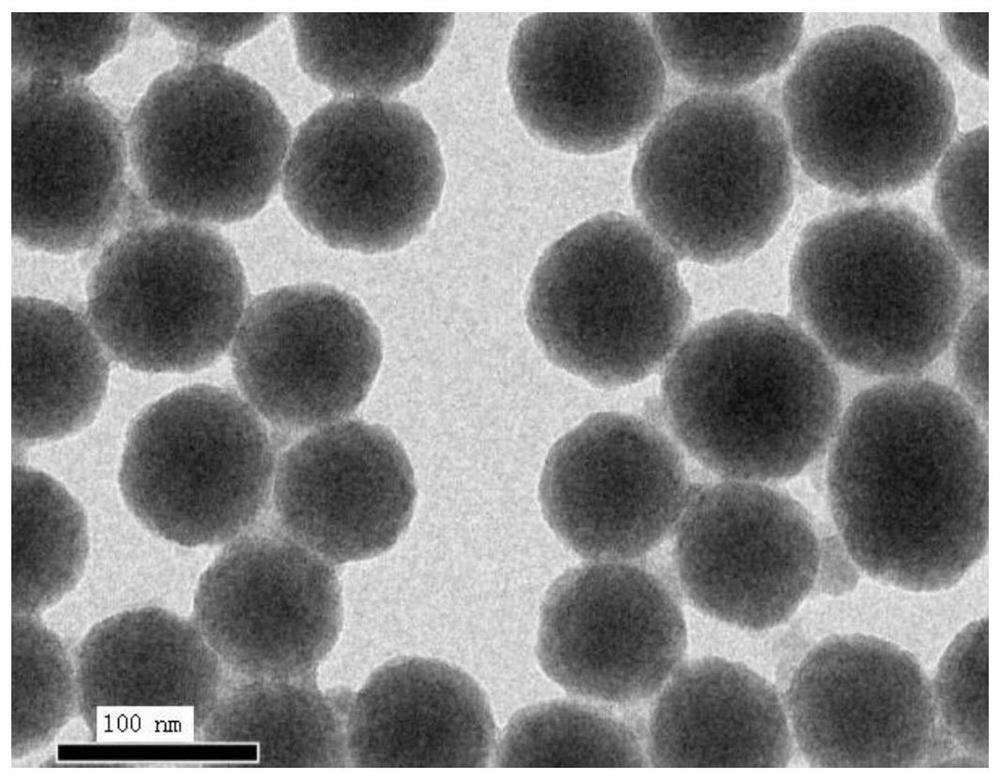

Image

Examples

Embodiment 1

[0033] Preparation of silicic acid: Weigh 100 g of anhydrous sodium silicate, stir and dissolve in 900 g of water to obtain a sodium silicate solution. The solution was successively passed through a cation exchange column and an anion exchange column (flow rate 10mL / min), and the part with pH2 Content 4.12%. Take 12.14mL of the above silicic acid, add water and dilute to SiO 2 The content is about 0.01%, and the silicic acid solution A is obtained; another fresh silicic acid solution is taken and diluted with water to SiO 2 content of 7.5%, to obtain silicic acid solution B.

[0034] Silicic acid aging: add 2.5g of ammonium acetate crystals to silica gel solution A, adjust the pH to 6-7, and keep it at 40°C for 6h, the viscosity reaches 10mPa·s, and then pass through a 0.2μm microporous membrane to obtain aged silicon Acid solution A (SiO 2 content of about 0.05%).

[0035] Seed crystal preparation: Add 1g of sodium hydroxide solution (1.0mol / L) to 1kg of aged silicic acid...

Embodiment 2

[0039] Preparation of silicic acid: Weigh 60 g of anhydrous sodium silicate, stir and dissolve in 940 g of water to obtain a sodium silicate solution. The solution was successively passed through a cation exchange column and an anion exchange column (flow rate 10mL / min), and the part with pH2 Content 2.39%. Take 105mL of the above silicic acid, add water and dilute to SiO 2 The content is about 0.1%, to obtain silicic acid solution A; take another fresh silicic acid, add water and dilute to SiO 2 content of 0.5%, to obtain silicic acid solution B.

[0040] Aging of silicic acid: Add 5g of ammonium acetate crystals to silica gel solution A, adjust the pH to 6-7, and keep it at 30°C for 24 hours, the viscosity reaches 15mPa·s, and then pass through a 0.2μm microporous membrane to obtain aged silicic acid Solution A (SiO 2 content of about 0.25%).

[0041] Seed crystal preparation: add 1g of sodium hydroxide solution (0.1mol / L) to 1kg of aged silicic acid solution A, and heat...

Embodiment 3

[0045] Preparation of silicic acid: Weigh 120 g of anhydrous sodium silicate, stir and dissolve in 880 g of water to obtain a sodium silicate solution. The solution was successively passed through a cation exchange column and an anion exchange column (flow rate 10mL / min), and the part with pH2 Content 5.24%. Take 191mL of the above silicic acid, dilute with water to SiO 2 The content is about 1% to obtain silicic acid solution A; take another fresh silicic acid and dilute it with water to SiO 2 content of 10%, to obtain silicic acid solution B.

[0046] Aging of silicic acid: Add 5g of ammonium acetate crystals to silica gel solution A, adjust the pH to 6-7, and keep it at 60°C for 1 hour, until the viscosity reaches 5mPa·s, and then pass through a 0.2μm microporous membrane to obtain aged silicic acid Solution A (SiO 2 content of about 1%).

[0047] Seed crystal preparation: add 2g sodium hydroxide solution (0.5mol / L) to 1kg aged silicic acid solution A, and heat to boili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com