Efficient polycarboxylate superplasticizer as well as preparation method and application thereof

A technology of polycarboxylic acid and water reducing agent, which is applied in the field of high-efficiency polycarboxylic acid water reducing agent and its preparation, can solve the problems of not being able to solve the problems of early polymerization reaction rate, increasing the production cost of water reducing agent products, etc. performance, increase reaction resistance, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

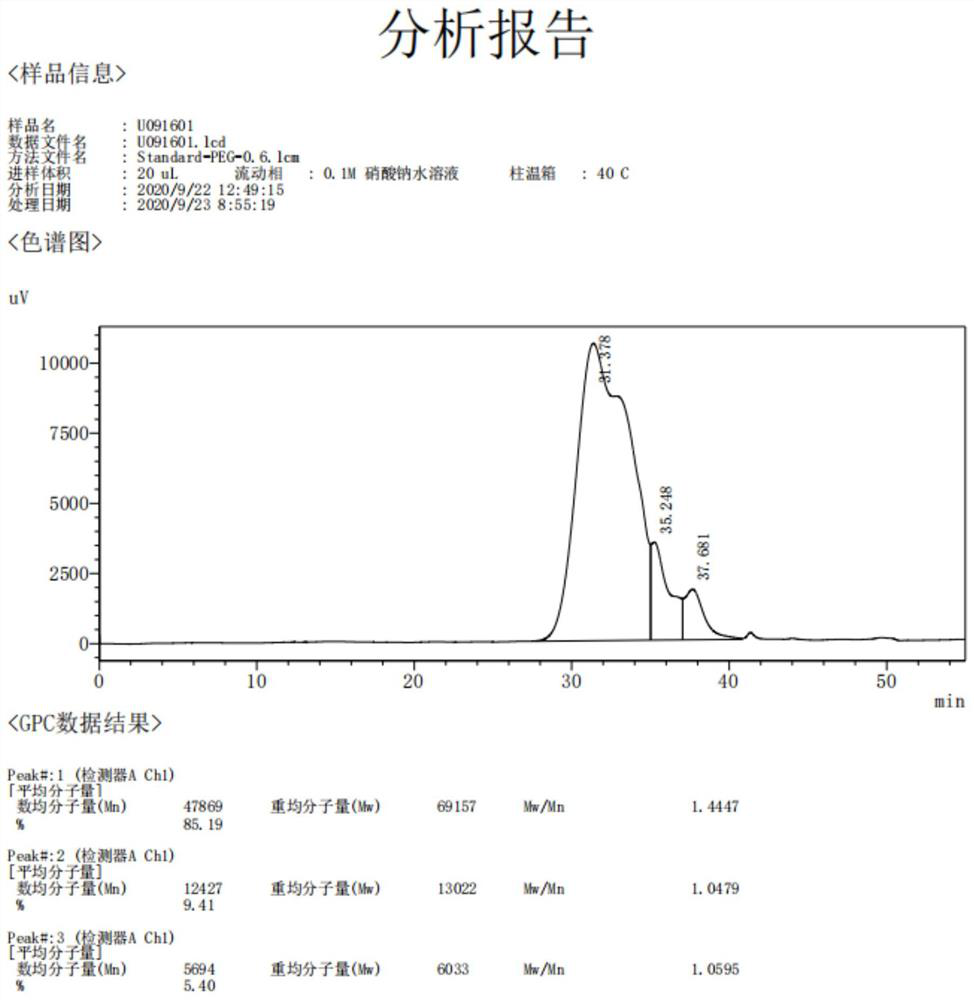

Embodiment 1

[0060] A preparation method of high-efficiency polycarboxylate water reducer, comprising the following steps:

[0061] 1) Put 0.1mol of polyether monomer EPEG-3000 (ethylene glycol monovinyl polyoxyethylene ether) in 200g of water and stir until completely dissolved, then add 0.12mol of acrylic acid, 0.08mol of low-activity small monomer Malay Acid anhydride, 0.9% mass concentration of polyether monomer, 30% hydrogen peroxide aqueous solution, 20 mg copper sulfate, 0.3% polyether monomer mass thioglycolic acid, no need to operate and control the reaction temperature of the system, the reaction system is close to normal temperature at 20-25°C Under conditions.

[0062] 2) Material A is a mixture of 0.25 mol of acrylic acid and 0.45% of the mass of polyether monomers used for thioglycolic acid, dissolved in water that is 4 times the total mass of acrylic acid and thioglycolic acid, and finally added with a low-activity small amount of 1.5% of the mass of polyether monomers used....

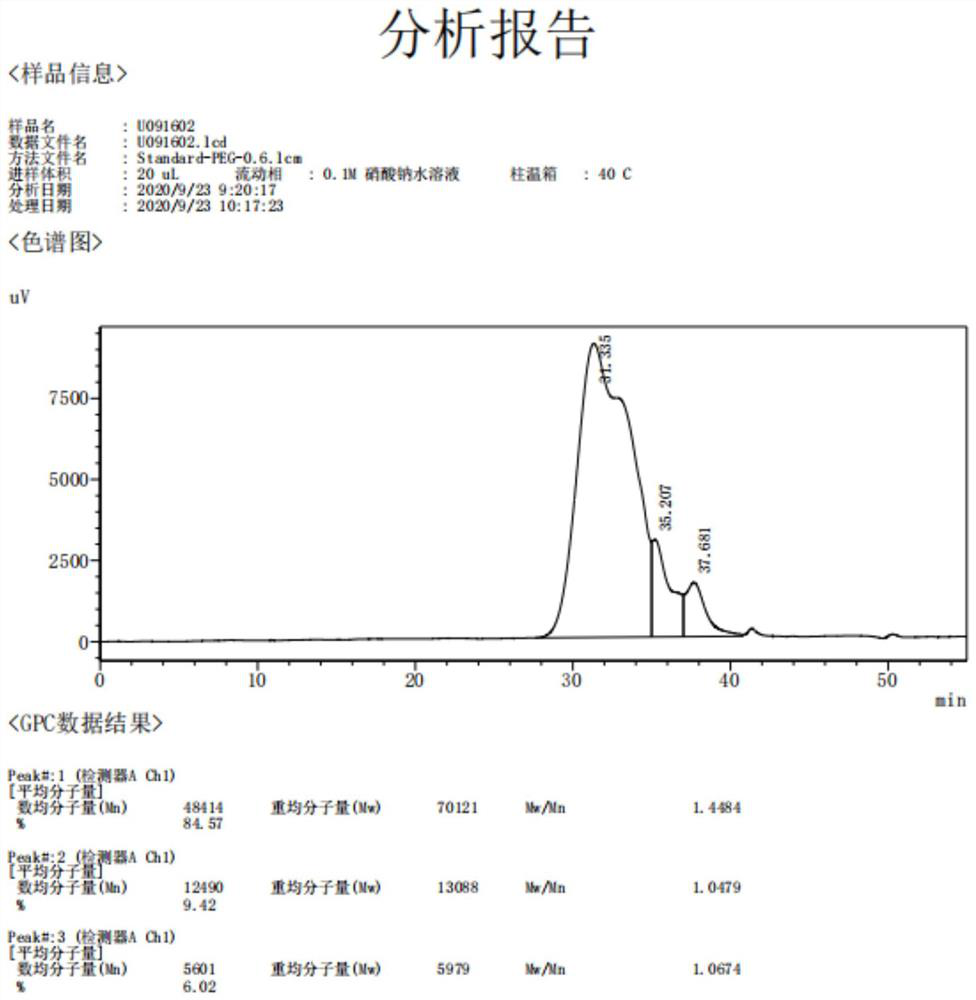

Embodiment 2

[0084] A preparation method of high-efficiency polycarboxylate water reducer, comprising the following steps:

[0085] 1) Put 0.1mol of polyether monomer EPEG-6000 (ethylene glycol monovinyl polyoxyethylene ether) in 800g of water and stir until completely dissolved, then add 0.18mol of acrylic acid and 0.03mol of low activity small monomer acrylic acid Hydroxyethyl ester, a 30% hydrogen peroxide aqueous solution with a mass concentration of 1.15% of the polyether monomer quality, 140 mg of copper sulfate, and 0.3% mercaptoacetic acid of the polyether monomer quality used, and the reaction system is at a temperature close to normal temperature of 20-25° C. No manipulation is required to control system temperature.

[0086] 2) Material A is 0.35mol of acrylic acid, step 1) a mixture of 0.75% polyether monomer mass of thioglycolic acid is dissolved in water 6 times the total mass of acrylic acid and thioglycolic acid, and finally 2.5% polyether monomer mass of low-activity polye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com