Etching solution composition and preparation method thereof

A technology of composition and etching solution, which is applied in the field of etching, can solve the problems of high production cost, etching residue, short shelf life, etc., and achieve the effect of low cost, small line width loss difference, and not easy to etch broken lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

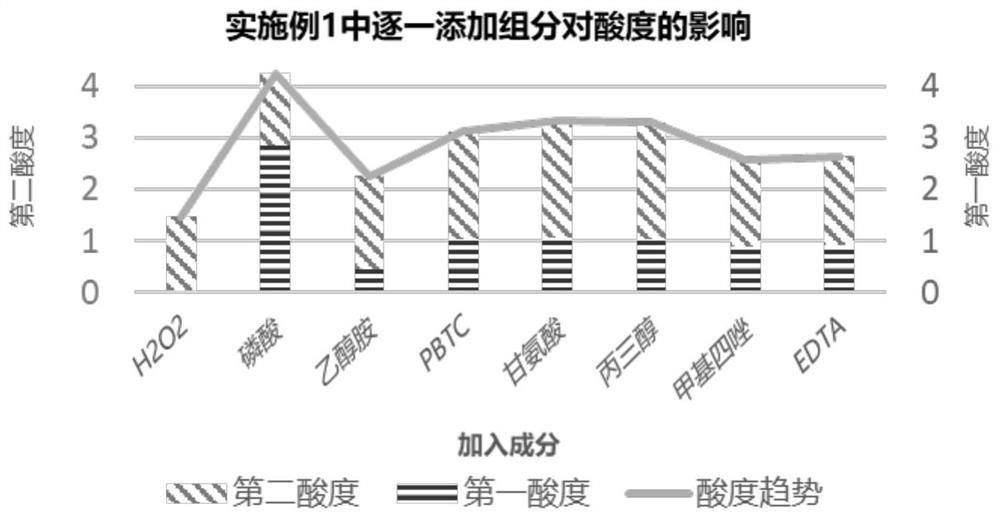

[0028] In the first embodiment of the method for preparing the etching solution composition of the present invention (hereinafter referred to as "the first preparation scheme"), the following components are added in order to prepare according to the ratio: add hydrogen peroxide in the preparation container, and then add the inorganic acid , then add a compound with both amine and alcohol groups, then add a pH regulator, then add an organic acid or amino acid, then add a hydrogen peroxide stabilizer, then add a metal ion chelating agent, and finally mix well; if there is an etching inhibitor, then Add etch inhibitor after adding hydrogen peroxide stabilizer. That is, in the first formulation scheme, the compound having both an amine group and an alcohol group is added immediately after the mineral acid.

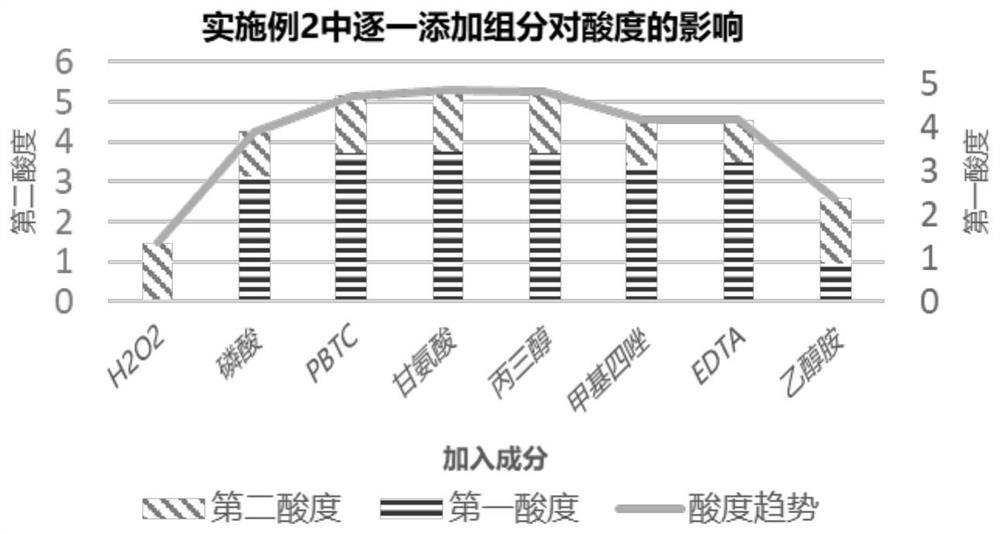

[0029] In the second embodiment of the method for preparing the etching solution composition of the present invention (hereinafter referred to as "the second preparation schem...

Embodiment 1-4 and comparative example 1-6

[0042] I. the preparation and test result of the etching solution composition of embodiment 1-4 and comparative example 1-6

[0043] Table 1 shows the composition content and preparation sequence of the etching solution compositions of Examples 1-4 and Comparative Examples 1-6 and the acidity of the obtained etching solution compositions. As shown in Table 1, the etching solution composition of Example 1 was prepared according to the first preparation scheme. Specifically, add 73g deionized water to a 200mL beaker, then add 15g hydrogen peroxide, then add 2g phosphoric acid, then add 3g ethanolamine, then add 2g PBTC, then add 1g glycine, then add 0.5g glycerol, then add 1.5g Methyl tetrazole, 2g of EDTA was finally added, and the components were mixed uniformly to obtain the etching solution composition of Example 1.

Embodiment 2

[0044] As shown in Table 1, the etching solution composition of Example 2 was prepared according to the second preparation scheme. Specifically, add 73g of deionized water to a 200mL beaker, then add 15g of hydrogen peroxide, then add 2g of phosphoric acid, then add 2g of PBTC, then add 1g of glycine, then add 0.5g of glycerol, then add 1.5g of methyl tetrazole, Then 2g of EDTA was added, and finally 3g of ethanolamine was added, and all components were mixed uniformly to obtain the etching solution composition of Example 2.

[0045] As shown in Table 1, the etching solution compositions of Comparative Examples 1-6 were prepared according to the first preparation scheme, that is, the preparation sequence was the same as that of Example 1, except that the addition amount of one component was changed for each Comparative Example. Specifically, the amount of ethanolamine added in Comparative Example 1 was 6g, the amount of ethanolamine added in Comparative Example 2 was 1g, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com