Etching composition and application thereof

A composition and etching technology, applied in the direction of surface etching compositions, semiconductor devices, chemical instruments and methods, etc., can solve the problems of bumps prone to side etching, incomplete and uneven etching, etc., and achieve circuit or solder joints. Good morphology, no damage or small damage, good etching uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The preparation method of the etching composition in the present invention can be any one known to those skilled in the art, such as physical blending.

[0056] The present invention also provides the application of the above etching composition, which is used for manufacturing display devices; further, the etching composition is used for making bumps on chips.

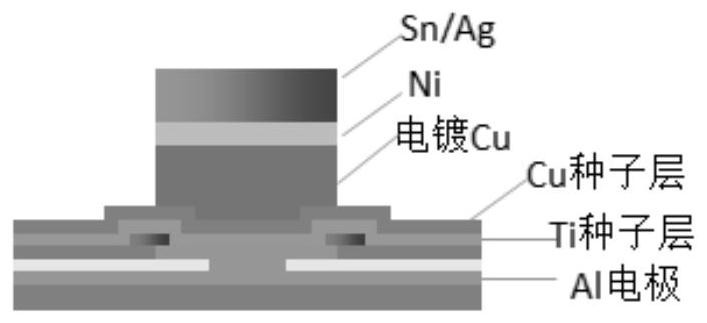

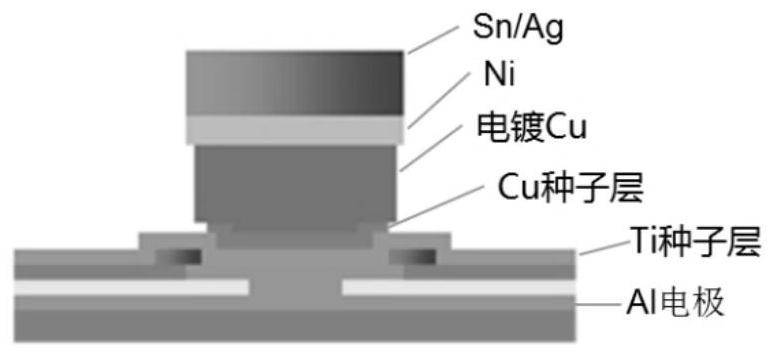

[0057] The chip of the present invention includes a bump and a seed layer under the bump; the bump includes an upper layer made of tin or tin alloy, and a lower layer made of nickel or nickel-copper alloy. The types of tin alloys mentioned in this application are not particularly limited, and generally refer to alloys composed of tin and copper, silver, lead and other metals. In some embodiments, an electroplating layer is further included between the bumps and the seed layer.

[0058] Such as figure 1 As shown, it is a schematic diagram of a chip bump, wherein the chip includes a bump and a seed layer below ...

Embodiment

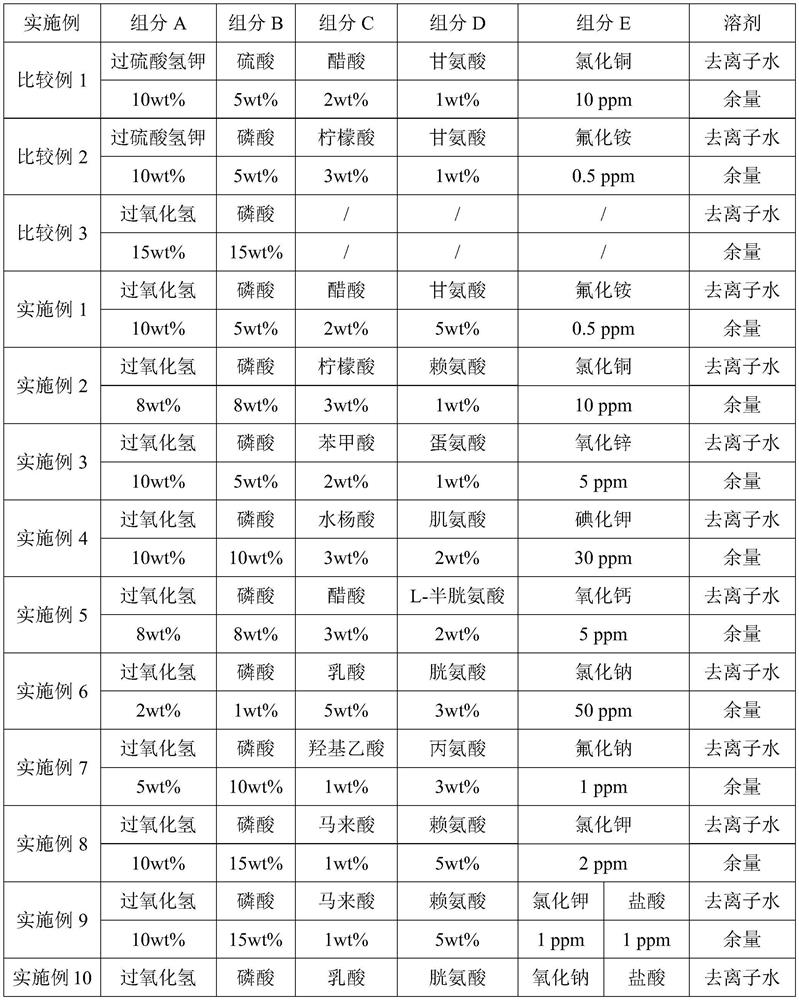

[0061] The technical solutions of the present invention are described in detail below through examples, but the protection scope of the present invention is not limited to the examples. Unless otherwise specified, the raw materials in the present invention are all commercially available.

[0062] The performance parameter test index of etching composition of the present invention:

[0063] 1. The amount of side etching CD loss, such as Figure 1~2 As shown, the shrinkage of electroplated copper in the horizontal direction before and after copper etching is called side etching loss (CD loss), and the unit is μm. After corrosion, electroplated copper and copper seed layer should be as flush as possible with the Ni or Sn / Ag layer. Shrinkage, so low CD is the best performance value, and the general application requirement is less than 1μm.

[0064] 2. The amount of undercut undercut, such as Figure 1~2 As shown, on one side of the bump, the amount of shrinkage of the copper se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com