Alkali-modified charcoal loaded zero-valent iron composite material as well as preparation method and application thereof

A technology of composite materials and biochar, applied in the direction of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problems of high cost and complicated preparation conditions, and achieve low cost, simple operation, The effect of increasing aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

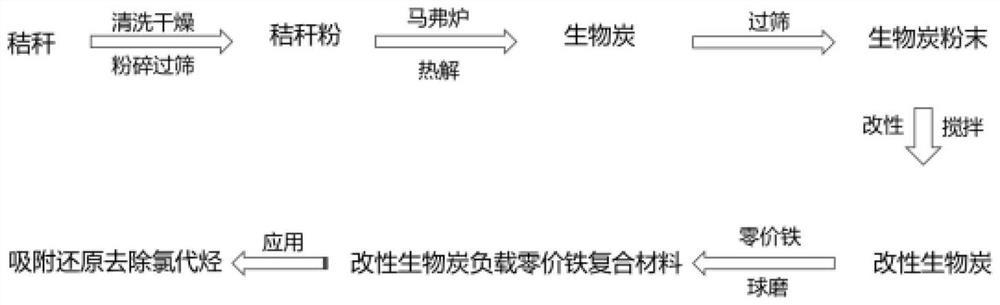

[0058] The preparation steps of an alkali-modified biochar-loaded zero-valent iron composite material and a method for removing chlorinated hydrocarbons in sewage by using the composite material of the present invention specifically include the following steps:

[0059] Step (a): washing the wheat straw with ultrapure water, drying it in a 105°C oven for 24h for later use;

[0060] Step (b): pulverize the dried wheat straw with a pulverizer and pass through a 10-mesh sieve;

[0061] Step (c): put the wheat straw powder in step (b) in a ceramic crucible, cover with a lid, place it in a muffle furnace, adopt an oxygen-limiting method, and heat up to 700°C at a heating rate of 10°C / min, and the residence time is 10°C. After 2 hours, the heating was stopped until the muffle furnace was naturally cooled to room temperature and then taken out, sealed and stored to obtain the original biochar;

[0062] Step (d): grinding the original biochar in step (c) with an agate mortar and pass...

Embodiment 2

[0072] The preparation steps of an alkali-modified biochar-loaded zero-valent iron composite material and a method for removing chlorinated hydrocarbons in sewage by using the composite material of the present invention specifically include the following steps:

[0073] Step (a): washing the wheat straw with ultrapure water, drying it in an oven at 80°C for 20h for use;

[0074] Step (b): pulverize the dried wheat straw with a pulverizer and pass through a 10-mesh sieve;

[0075] Step (c): put the wheat straw powder in step (b) in a ceramic crucible, cover with a lid, place it in a muffle furnace, adopt an oxygen-limiting method, and heat up to 300 °C at a heating rate of 8 °C / min, and the residence time for 1.5h, then stop heating until the muffle furnace is naturally cooled to room temperature, then take it out, seal it and store it to obtain the original biochar;

[0076] Step (d): grinding the original biochar in step (c) with an agate mortar and passing through a 50-mesh s...

Embodiment 3

[0083] The preparation steps of an alkali-modified biochar-loaded zero-valent iron composite material and a method for removing chlorinated hydrocarbons in sewage by using the composite material of the present invention specifically include the following steps:

[0084] Step (a): washing the wheat straw with ultrapure water, drying it in an oven at 100°C for 18h for later use;

[0085] Step (b): pulverize the dried wheat straw with a pulverizer and pass through a 10-mesh sieve;

[0086] Step (c): put the wheat straw powder in step (b) in a ceramic crucible, cover with a lid, place it in a muffle furnace, adopt an oxygen-limiting method, and heat up to 500 °C at a heating rate of 9 °C / min, and the residence time is 9 °C / min. for 1.5h, then stop heating until the muffle furnace is naturally cooled to room temperature, then take it out, seal it and store it to obtain the original biochar;

[0087] Step (d): grinding the original biochar in step (c) with an agate mortar and passi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore area | aaaaa | aaaaa |

| Pore area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com