Preparation method and application of positive electrode polysulfide buffer layer for improving cycle performance of lithium-sulfur battery

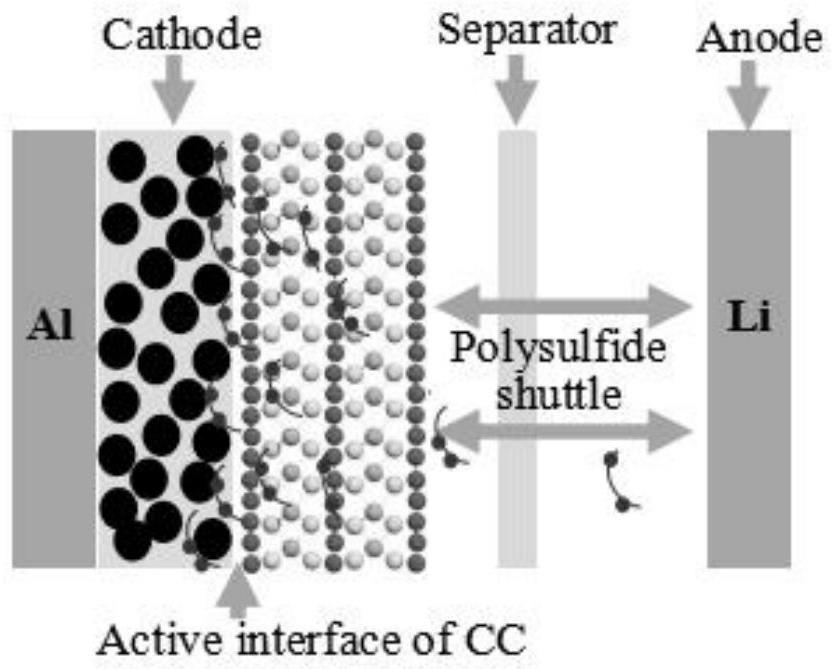

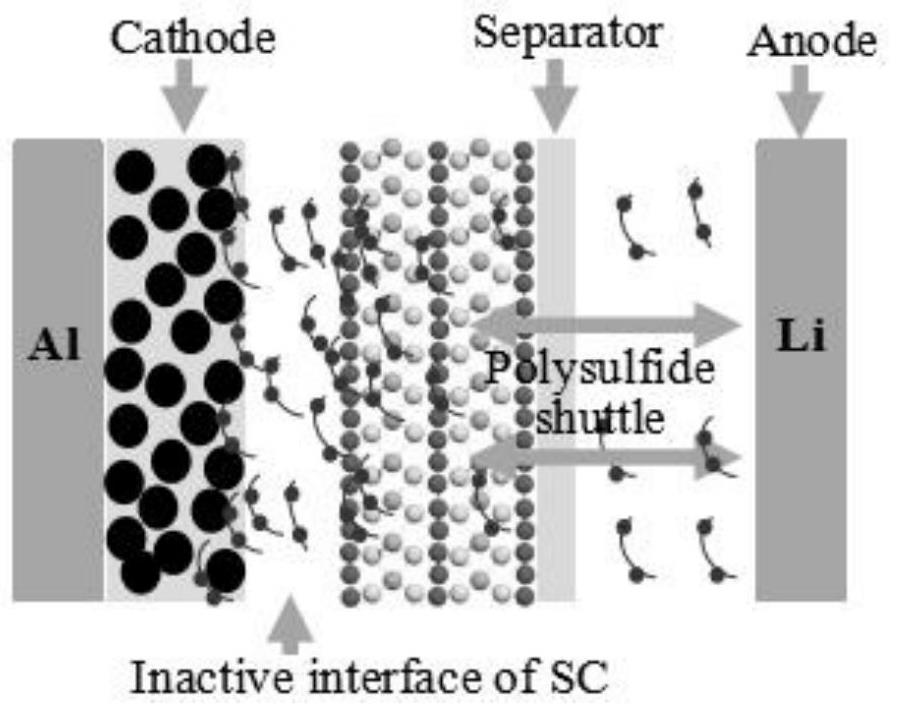

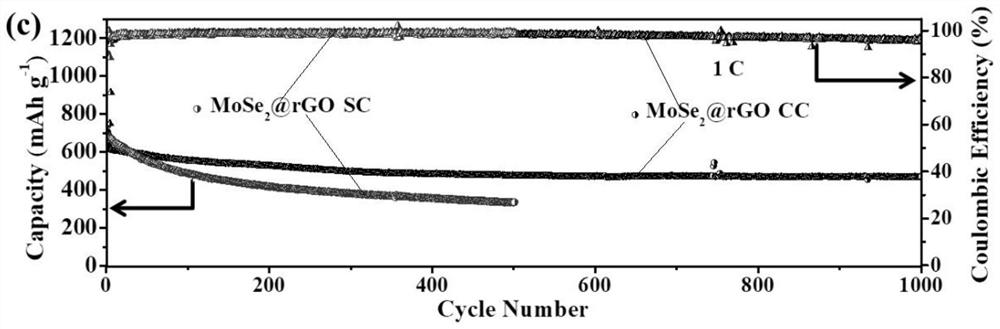

A lithium-sulfur battery, cycle performance technology, applied in the direction of non-aqueous electrolyte battery electrodes, battery components, circuits, etc., can solve the problems of active material loss, dead sulfur, etc., to inhibit aggregation, improve utilization rate, and promote reversible conversion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A MoSe 2 The preparation method of @rGO composite material includes the following steps:

[0031] Preparation of GO:

[0032] 1) First take 1g of graphite powder and put it in a clean beaker, then pour 25mL of concentrated sulfuric acid into the beaker, and stir for 1 hour in a zero-degree environment until the powder and liquid are evenly stirred.

[0033] 2) Slowly add 3.5 g of potassium permanganate to the above mixture solution, and then let it stand at 0° C. for 1 hour.

[0034] 3) Put the beaker at room temperature for ten minutes and then move it to a 35°C oil bath for 24 hours.

[0035] 4) After the reaction, slowly add 100 mL of deionized water into the beaker, and then put the beaker in an oil bath at 90°C for 10 minutes.

[0036] 5) Take out the beaker in 4) and cool it down to about 60°C, then transfer the liquid in it to a large 200mL beaker.

[0037] 6) Add H to the large beaker 2 o 2 The excess potassium permanganate was removed from the solution (3...

Embodiment 2

[0045] A method for preparing a positive electrode polysulfide buffer layer that improves the cycle performance of lithium-sulfur batteries, using the MoSe provided in Example 1 2 @rGO composite material, including the following steps:

[0046] Weigh 20mg MoSe 2 The @rGO composite was placed in an agate mortar, PVDF was added dropwise, (MoSe 2 The mass ratio of @rGO to PVDF is 9:1), then add NMP (two or three drops) dropwise and grind it thoroughly with a mortar to make it evenly mixed to obtain a black slurry;

[0047] Coat the prepared black slurry on the substrate (aluminum foil) coated with the positive electrode material again with a coating machine, and then place it in a vacuum oven at 60°C for 6 hours to dry to obtain an improved lithium-sulfur battery on the positive electrode material. Positive polysulfide buffer layer for cycle performance.

Embodiment 3

[0049] A method for preparing an electrode sheet, comprising the following steps:

[0050] Choose aluminum foil;

[0051] Preparation of cathode material on aluminum foil:

[0052] 1) Put the sublimated sulfur and acetylene black in a drying oven to dry first, then weigh them into an agate mortar according to the mass ratio of 3:1, add alcohol and grind vigorously until the alcohol is completely evaporated, then add alcohol to grind, repeat four times About half an hour in a vacuum drying oven;

[0053] 2) Mix the dried material and PVDF in a mass ratio of 9:1, add NMP and stir until the slurry is silky, the mass ratio of dried material to NMP is 1:1, and use an automatic coating machine to coat the The adjusted black slurry is coated on aluminum foil and dried in a vacuum oven at 60°C for 24 hours;

[0054] Prepare the positive electrode polysulfide buffer layer provided by Example 2 on the positive electrode material:

[0055] 3) Weigh 20mg MoSe 2 The @rGO composite was p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com