Nanosheet hydrated sodium vanadyl phosphate positive electrode material as well as preparation method and application thereof

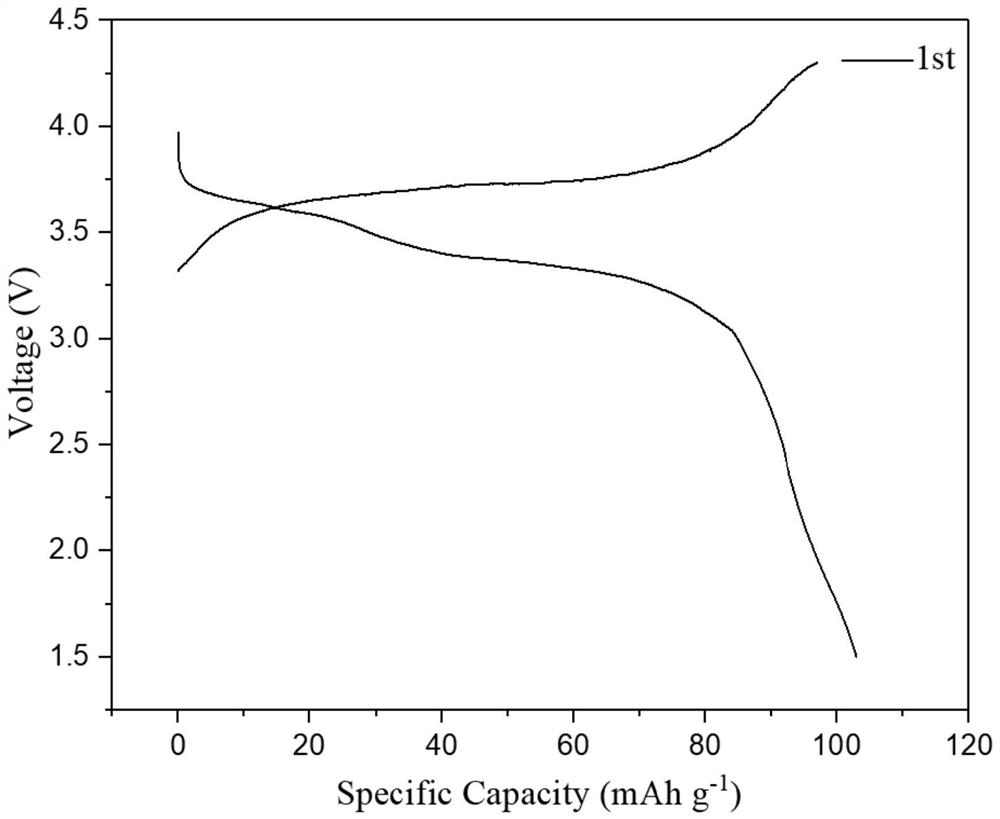

A hydrated sodium vanadyl phosphate, nano-sheet technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve problems such as low working voltage, improve working voltage, facilitate embedding or de-embedding, promote The effect of reversible transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

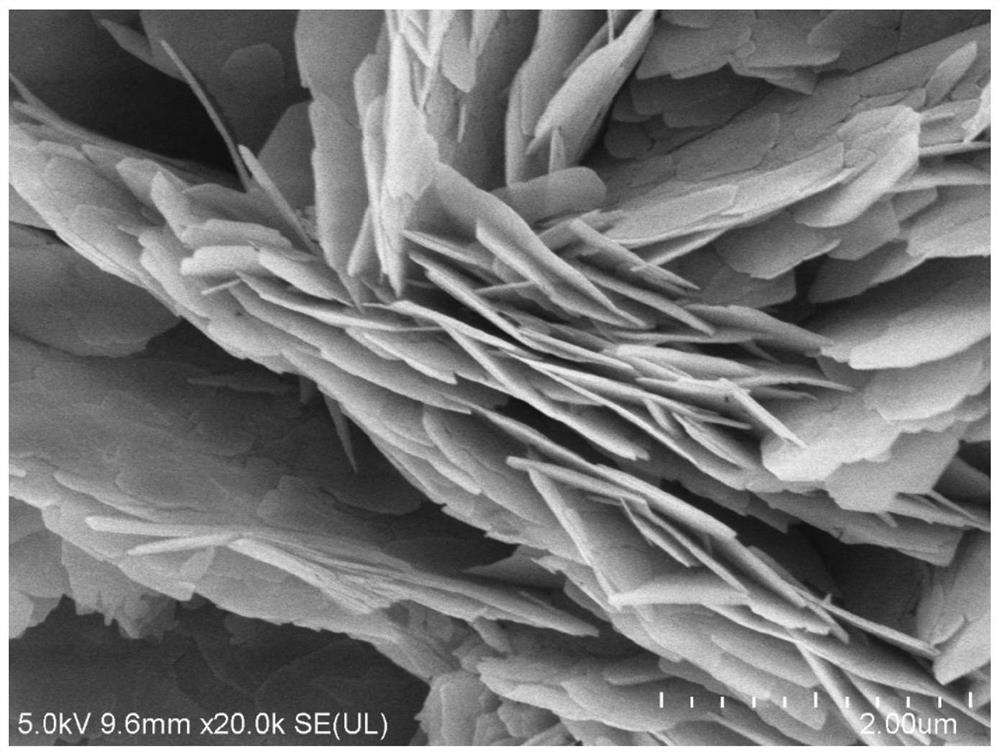

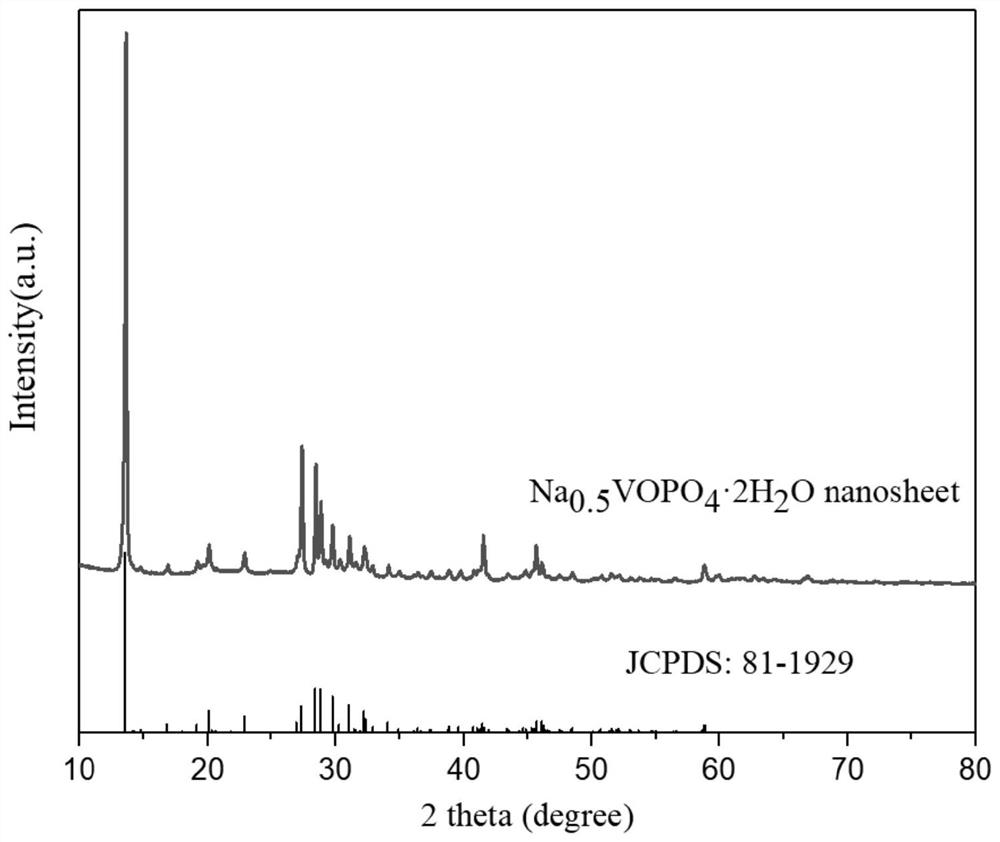

[0033] Concretely, the preparation method of a kind of nano flake hydrated sodium vanadyl phosphate cathode material of the present invention comprises the following steps:

[0034]Step 1. Add a certain amount of sodium source and phosphorus source to deionized water, and use magnetic stirring to dissolve them in deionized water as an electrolyte solution. Then use vanadium as an anode and platinum as a cathode. The platinum sheet is used as a counter electrode to carry out the electrochemical stripping reaction of the vanadium sheet, the reaction voltage of the electrochemical stripping reaction is 5-20V, and the reaction time is 2-10min.

[0035] The sodium source in the above step 1 is at least one of sodium sulfate, sodium chloride, sodium carbonate, sodium dihydrogen phosphate, sodium bicarbonate and sodium nitrate; the phosphorus source in the step 1 is ammonium dihydrogen phosphate, phosphoric acid, phosphoric acid At least one of sodium dihydrogen and metaphosphoric ac...

Embodiment 1

[0041] Accurately weigh 3.551g (25mmol) sodium sulfate and 2.8755g (25mmol) ammonium dihydrogen phosphate, add to 50mL deionized water, stir magnetically at room temperature for 10min, transfer the solution to a 100mL electrolytic cell, and then accurately measure the area of one piece 2cm 2 1. A vanadium sheet with a thickness of 0.2mm, with the vanadium sheet as the anode and the platinum sheet as the cathode, the electrode spacing is adjusted to 3cm, and the electrochemical workstation is used to adjust the voltage to 20V for electrochemical stripping reaction for 3min. Then use a platinum sheet to replace the anode. At this time, both the cathode and the anode are platinum sheets, and keep the cathode and the anode at a distance of 3 cm. Use a voltage of 10V to continue the reaction for 20 minutes. Finally, the reaction product is centrifugally washed with deionized water and absolute ethanol. each three times, and vacuum-dried at 60° C. for 12 hours to obtain nanosheet-...

Embodiment 2

[0044] Accurately weigh 3.551g (25mmol) sodium sulfate and 0.560g (5mmol) ammonium dihydrogen phosphate, add them to 50mL deionized water, stir magnetically at room temperature for 10min, transfer the solution to a 100mL electrolytic cell, and then accurately measure the area of a piece 1.5cm 2 1. A vanadium sheet with a thickness of 0.1mm, with the vanadium sheet as the anode and the platinum sheet as the cathode, the distance between the electrodes is adjusted to 2cm, and the electrochemical workstation is used to adjust the voltage to 10V to perform the electrochemical stripping reaction for 3min. Then use a platinum sheet to replace the anode. At this time, both the cathode and the anode are platinum sheets, and keep the cathode and the anode at a distance of 2 cm. Use a voltage of 15V to continue the reaction for 15 minutes. Finally, the reaction product is centrifugally washed with deionized water and absolute ethanol. each three times, and vacuum-dried at 80° C. for 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com