A preparation method of a three-dimensional graphene-titanium-based fiber-lead powder lead-acid battery negative plate

A lead-acid battery and graphene technology, applied in the direction of lead-acid battery, lead-acid battery construction, battery electrodes, etc., can solve the problems of complex graphene-based hydrogel process, insufficient performance improvement, and difficulty in industrial production. Achieve the effects of inhibiting irreversible sulfation, preventing shedding, improving specific capacity and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

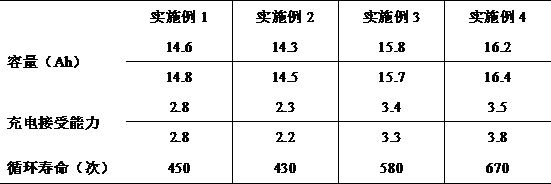

Examples

Embodiment 1)

[0023] Graphene was placed in a mixed solution of concentrated sulfuric acid with a mass fraction of 70% and concentrated nitric acid with a mass fraction of 68%. After washing to neutrality, hydrophilic graphene is obtained after natural air drying.

[0024] The hydrophilic graphene 1.5g obtained after air-drying is dispersed in deionized water, and 15 Kg of lead powder with a particle diameter of 0.5 μm is added to stir and disperse to obtain a graphene-lead powder dispersion.

[0025] The graphene-lead powder dispersion was quickly frozen with liquid nitrogen for 1 min, completely dried, placed in a tube furnace, filled with argon, and heat-treated at 400 °C for 6 h to obtain a graphene-lead powder negative electrode composite with a three-dimensional network structure.

[0026] Add 12 Kg of graphene-lead powder negative electrode composite material with three-dimensional network structure, 37.5 g of acetylene black, 120 g of barium sulfate, 18 g of lignin, 24 g of humic ac...

Embodiment 2)

[0030] Graphene was placed in a mixed solution with a mass fraction of 98% concentrated sulfuric acid and 65% concentrated nitric acid, the volume ratio of concentrated sulfuric acid to concentrated nitric acid was 3:1, refluxed at 80 °C for 4 h, suction filtered, deionized water After washing to neutrality, hydrophilic graphene is obtained after natural air drying.

[0031] The hydrophilic graphene 150g obtained after air-drying is dispersed in deionized water, and 15 Kg of lead powder with a particle diameter of 10 μm is added to stir and disperse to obtain a graphene-lead powder dispersion.

[0032] The graphene-lead powder dispersion was quickly frozen with liquid nitrogen for 5 minutes, completely dried, placed in a tube furnace, filled with argon mixed gas, and heat-treated at 600 °C for 4 hours to obtain a graphene-lead powder negative electrode composite material with a three-dimensional network structure .

[0033] Add 12 Kg of graphene-lead powder negative electrode...

Embodiment 3)

[0037] Graphene was placed in a mixed solution with a mass fraction of 98% concentrated sulfuric acid and 97.5% concentrated nitric acid, the volume ratio of concentrated sulfuric acid to concentrated nitric acid was 4:1, refluxed at 100 °C for 2 h, suction filtered, deionized water After washing to neutrality, hydrophilic graphene is obtained after natural air drying.

[0038] The hydrophilic graphene 60g obtained after air-drying was dispersed in deionized water, and 15 Kg of lead powder with a particle diameter of 20 μm was added to stir and disperse to obtain a graphene-lead powder dispersion.

[0039] The graphene-lead powder dispersion was quickly frozen with liquid nitrogen for 20 min, completely dried, placed in a tube furnace, fed with hydrogen, and heat-treated at 800 °C for 2 h to obtain a graphene-lead powder negative electrode composite with a three-dimensional network structure.

[0040] Add 12 Kg of graphene-lead powder negative electrode composite material with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com