High-temperature sealing coating for stopper rod for continuous casting

A high-temperature sealing and coating technology, used in coating, casting equipment, casting melt containers, etc., can solve the problems of reducing the number of continuous pouring furnaces in the tundish, worsening the purity of steel, and increasing the loss of aluminum in the steel. Inhaled air and argon leakage, stable air permeability, improved product expansion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific examples.

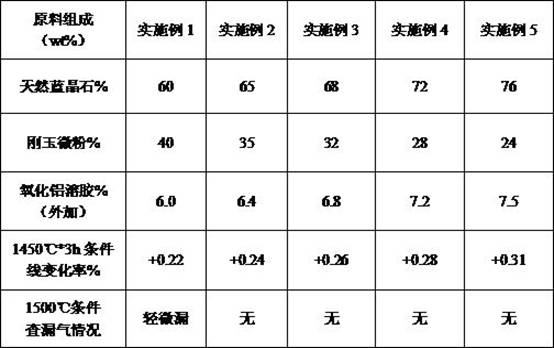

[0019] A high-temperature sealing coating for stopper rods for continuous casting. The raw materials of the coating include 60-76% of kyanite, 24-40% of corundum micropowder, and 6.0-7.5% of aluminum oxide sol. Kyanite is a natural refractory raw material mineral, which has various forms of Al 2 o 3 .SiO 2 or Al 2 SiO 5 , is the sediment of the original clay composition, which is metamorphosed under the condition of high temperature and high pressure under the action of strong extrusion shear stress. It is an anhydrous aluminosilicate mineral and belongs to the raw material of high alumina mineral. Mullite produced by calcining kyanite has high temperature stability, low expansion, good fire resistance and high load capacity at high temperature. At the baking temperature of 1100~1450°C, the mullite formed by the reaction of alumina sol and the silicon oxide component in k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com