Silane modified polyether sealant as well as preparation method and application thereof in prefabricated building

A silane-modified polyether and sealant technology, which is applied in the direction of polyether adhesives, adhesives, adhesive types, etc., can solve the specific requirements for thermal conductivity, fire and flame retardant performance, environmental protection, and sealants are easy to harden , unfavorable application and other problems, to achieve excellent physical properties and adhesion, low thermal conductivity, low density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In the preparation raw material of the present invention, 0.1-50 parts by weight of hollow glass microspheres are introduced, preferably 10-48 parts by weight. Hollow glass microspheres are spherical powder materials with a hollow structure; preferably, the hollow glass microspheres of the present invention have a true density of 0.12 to 0.70 g / cm 3 , preferably 0.12~0.62g / cm 3 ; The particle size is in the range of 5-100 μm, preferably at least one of the average particle size in the range of 8-90 μm. Hollow glass microspheres in preferred embodiments of the present invention have a true density of 0.37 to 0.39 g / cm 3 , particle size D90: 65μm, and / or, true density 0.21~0.24g / cm 3 , particle size D90: 70 μm.

[0035] Moreover, the raw material of the silane-modified polyether sealant includes 0.1-50 parts by weight of silica airgel, preferably 1-40 parts by weight, and the added amount does not exceed 20% by weight of the matrix resin. Silica airgel is usually a li...

Embodiment 1

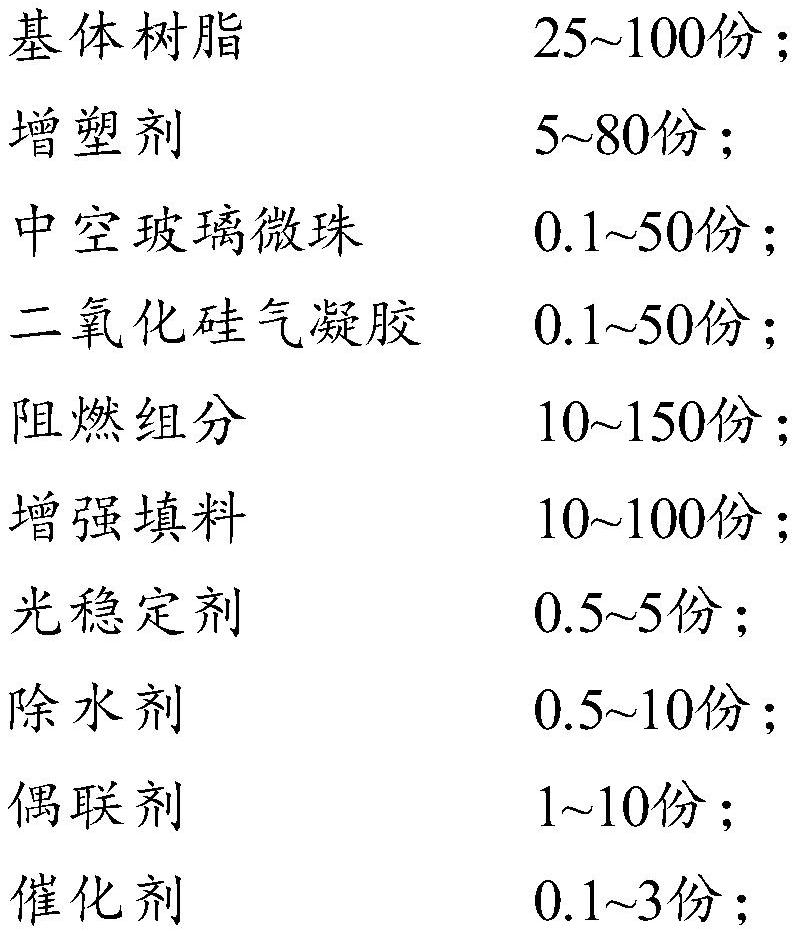

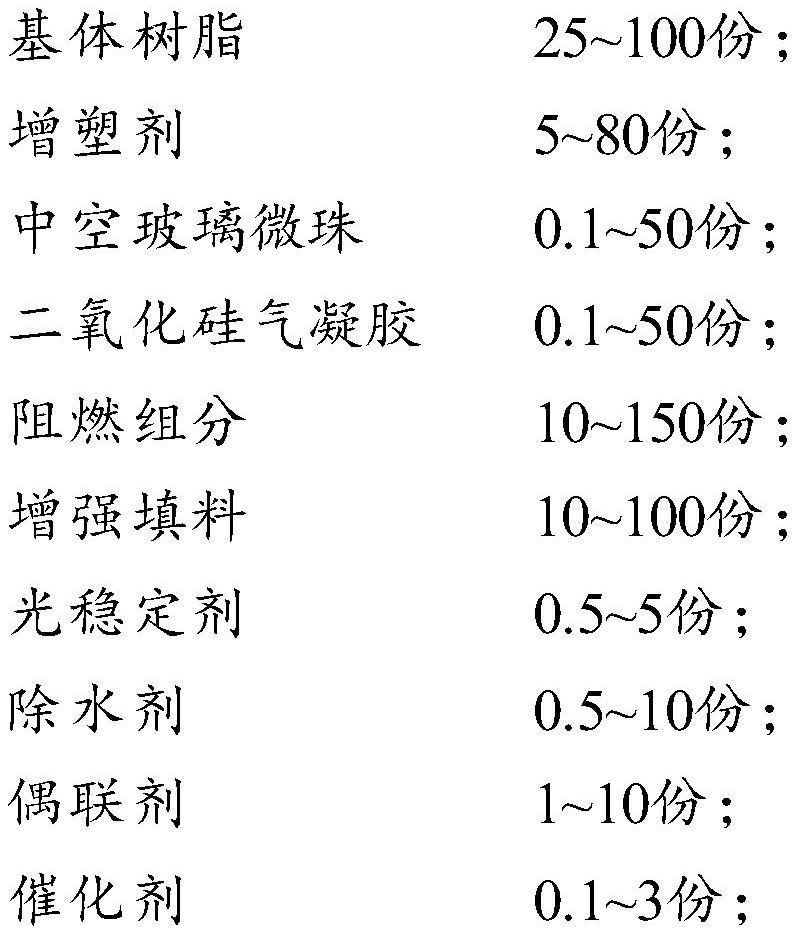

[0066] This embodiment is a novel silane-modified polyether sealant for prefabricated buildings, which comprises the following raw materials mixed in parts by weight, see Table 1:

[0067] The preparation raw material of table 1 embodiment 1

[0068]

[0069] The preparation method is as follows:

[0070] 1) Dry hollow glass microspheres, flame retardant fillers, reinforcing fillers, titanium dioxide, and silica airgel in a drying oven at 100-110°C for 4 hours.

[0071] 2) Weigh each raw material according to the above ratio, add silane-modified polyether resin, liquid flame retardant, plasticizer, anti-fungal agent and water remover to the double planetary mixer at room temperature, stir and mix at a speed of 20-40HZ 5-10min;

[0072] 3) Then add the dried flame-retardant filler, reinforcing filler, titanium dioxide, and silica airgel, stir at 20-40HZ for 3-10min, switch to high-speed stirring at 30-50HZ, turn on the vacuum, and the vacuum degree is 0.09± Continue to st...

Embodiment 2

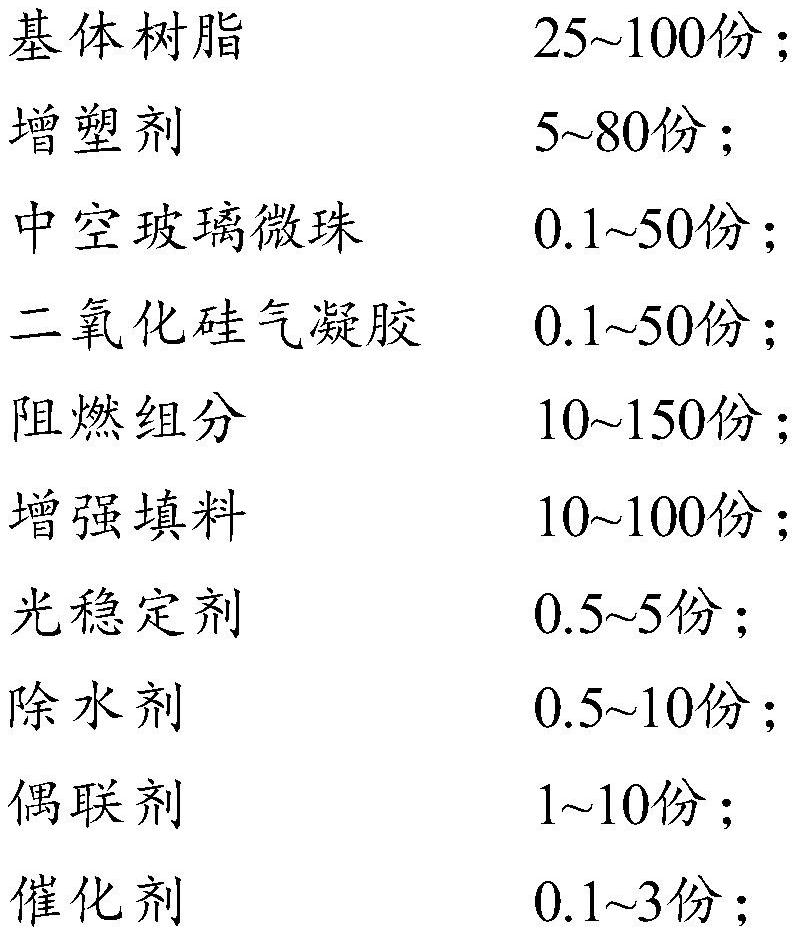

[0077] This example is a novel silane-modified polyether sealant for prefabricated buildings, which is prepared by mixing the following raw materials in parts by weight, see Table 2; the preparation method is the same as that of Example 1.

[0078] The preparation raw material of table 2 embodiment 2

[0079]

[0080]

PUM

| Property | Measurement | Unit |

|---|---|---|

| True density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com