Filling material for underwater acoustic equipment electronic component encapsulation and acoustic array cable and preparation method of filling material

A technology for underwater acoustic equipment and electronic components, which is applied in the field of potting of electronic components of underwater acoustic equipment, filling materials for sound array cables and their preparation, and can solve the problems of high water permeability and unsuitability for sound array cables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

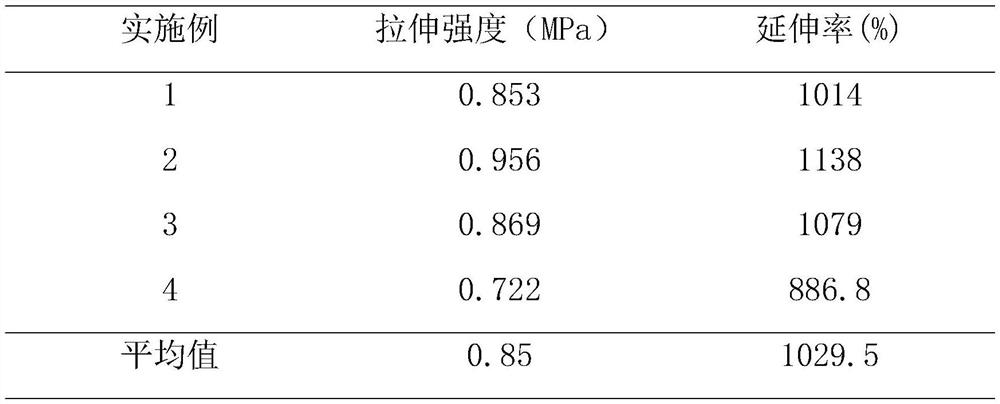

Embodiment 1

[0029] The specific process of the preparation method of the novel underwater acoustic casting polyurethane material involved in this embodiment is: add 40g hydroxyl-terminated epoxidized polybutadiene (EHTPB), 25g dimer acid diisocyanate (DDI), and 2g chain extender Stir evenly in the container, then add 5mg of catalyst, after vacuum defoaming treatment, pour into metal mold, and cure at 60°C for 18 hours.

Embodiment 2

[0031] The specific process of the preparation method of the novel underwater acoustic casting polyurethane material involved in this embodiment is: add 52g hydroxyl-terminated epoxidized polybutadiene (EHTPB), 25g dimer acid diisocyanate (DDI), and 2g chain extender Stir evenly in the container, then add 30mg of catalyst, after vacuum defoaming treatment, pour into metal mold, and solidify at 80°C for 3 hours.

Embodiment 3

[0033] The specific process of the preparation method of the novel underwater acoustic casting polyurethane material involved in this embodiment is: add 38g hydroxyl-terminated epoxidized polybutadiene (EHTPB), 20g dimer acid diisocyanate (DDI), and 2g chain extender Stir evenly in the container, then add 30mg of catalyst, after vacuum defoaming treatment, pour into metal mold, and solidify at 80°C for 3 hours.

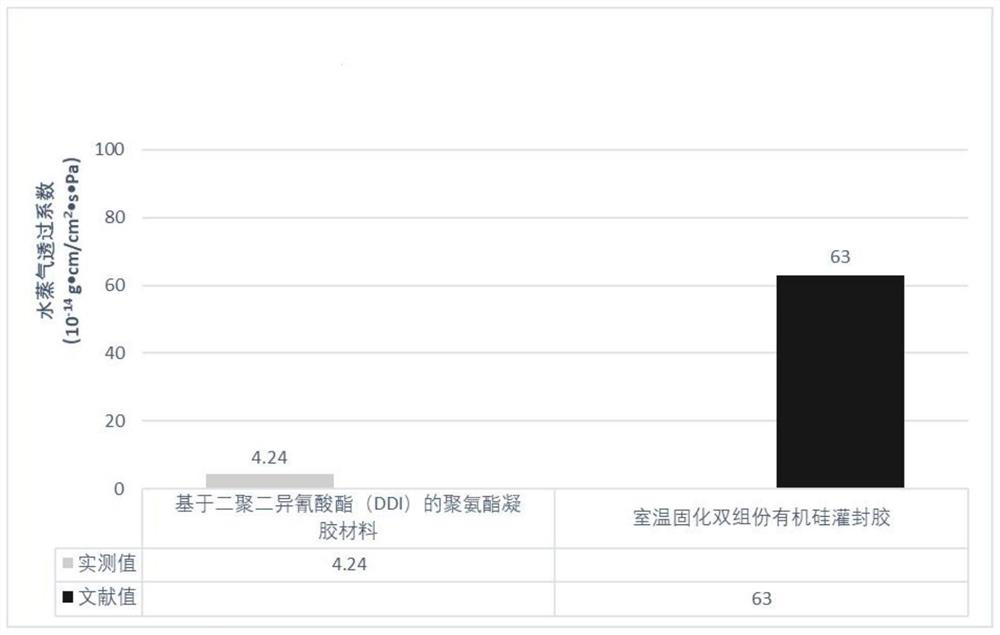

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water vapor transmission coefficient | aaaaa | aaaaa |

| Water vapor transmission coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com