Preparation method and application of nano-copper catalyst

A catalyst and nano-copper technology, which is applied to the preparation of nano-copper catalysts, and the preparation field of ultra-stable nano-copper prepared by electrochemical deposition, achieves the effects of simple preparation method, inhibiting surface copper from being oxidized, and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) The preparation concentration is 0.1mol L -1 Potassium bicarbonate solution, 0.01mol copper formate and 0.02mol sodium tartrate were dissolved in 100mL potassium bicarbonate solution to obtain a precursor solution.

[0031] (2) Place the carbon paper in the precursor solution in step (1), and use 50mL min -1rate into CO 2 Gas, apply 0.1Acm -2 A constant current was used to obtain a nano-copper catalyst after electrochemical reduction for 5 min.

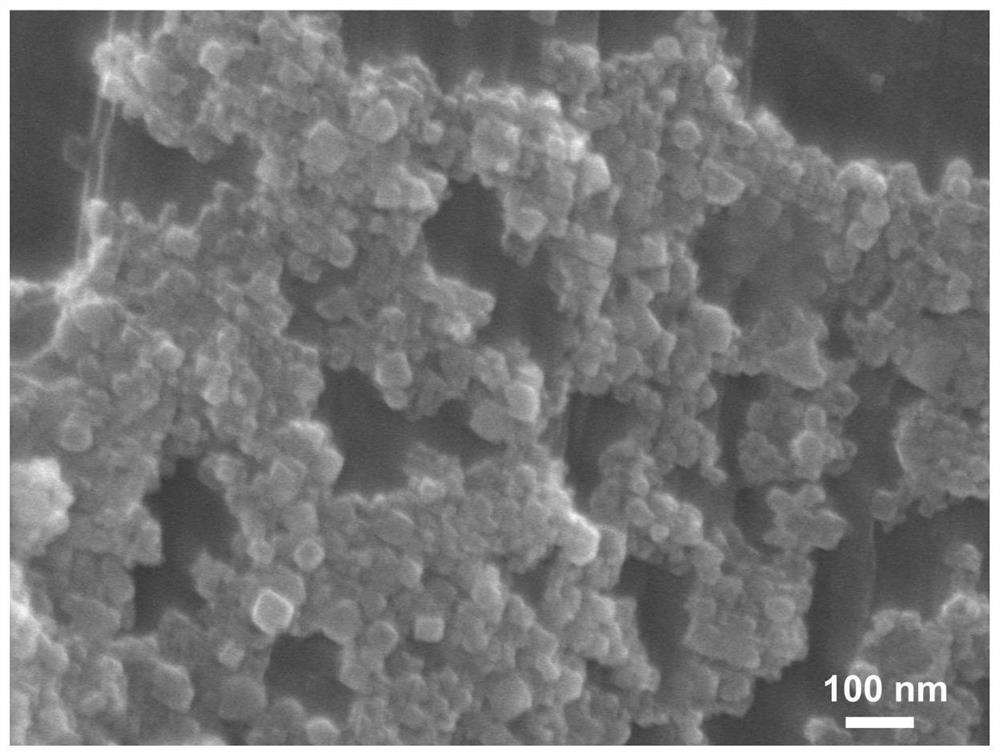

[0032] figure 1 It is the scanning electron microscope image of the nano-copper catalyst prepared in Example 1. The nano-copper is in the shape of stacked particles, and the particle size is about 80-120nm.

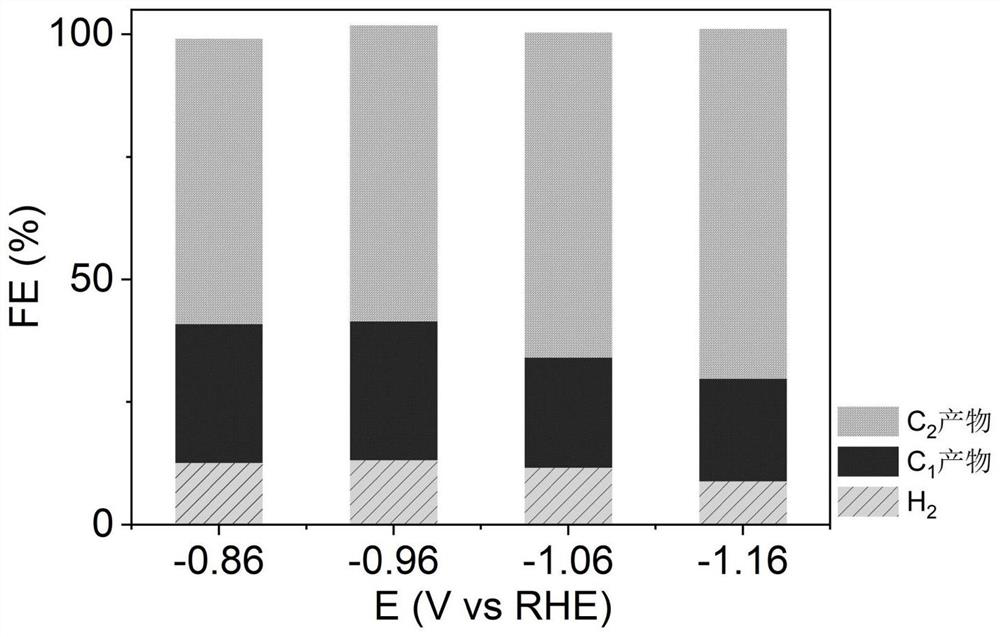

[0033] figure 2 It is the electrocatalytic reduction CO of the nanometer copper catalyst prepared in embodiment 1 2 Performance diagram, it can be seen that the nano-copper catalyst can convert CO 2 Electrocatalytic conversion into a variety of high value-added C 2 The product has a Faraday efficiency of 71.3%...

Embodiment 2

[0036] (1) The preparation concentration is 0.1mol L -1 Potassium bicarbonate solution, 0.01mol copper acetate and 0.02mol sodium sulfonate were dissolved in 100mL potassium bicarbonate solution to obtain a precursor solution.

[0037] (2) Place the carbon paper in the precursor solution in step (1), and use 50mL min -1 rate into CO 2 Gas, apply 0.1A cm -2 A constant current was used to obtain a nano-copper catalyst after electrochemical reduction for 5 min.

Embodiment 3

[0039] (1) The preparation concentration is 0.1mol L -1 Potassium bicarbonate solution, 0.01mol copper acetylacetonate and 0.02mol sodium carboxylate were dissolved in 100mL potassium bicarbonate solution to obtain a precursor solution.

[0040] (2) Place the carbon paper in the precursor solution in step (1), and use 50mL min -1 rate into CO 2 Gas, apply 0.1A cm -2 A constant current was used to obtain a nano-copper catalyst after electrochemical reduction for 5 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com