Special tack coat for microwave heat control type ultra-thin pavement and construction method of special tack coat for microwave heat control type ultra-thin pavement

A sticky oil, extremely thin technology, applied in the direction of roads, roads, and on-site coagulation pavement, etc., to slow down the heat dissipation rate, improve the bonding performance, and balance the viscoelasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

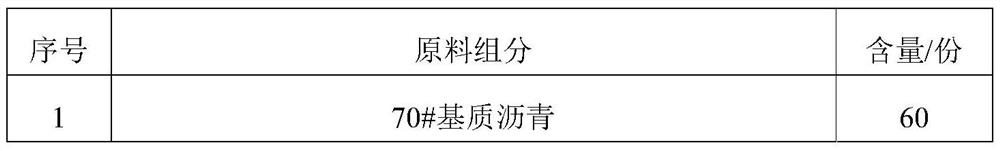

[0030] The component raw materials of the emulsified modified asphalt used in Example 1 are shown in Table 1 below.

[0031] Table 1 Raw material components of emulsified modified asphalt

[0032] serial number Raw material components Content / part 1 70# matrix asphalt 40 2 coal tar pitch 6 3 barite powder 1 4 Old shoe sole rubber particles 3 5 Modified Petroleum Resin 1 6 Linear Low Density Polyethylene Powder 1 7 Cationic Asphalt Emulsifier 0.3 8 70℃ hot water 49.7

[0033] The preparation method of the emulsified modified asphalt of this embodiment comprises the steps:

[0034] (1) Preparation of modified asphalt: heat 40 parts of 70# base asphalt to 165 ° C, stir and keep warm properly, add 6 parts of coal tar pitch, 1 part of barite powder, 3 parts of old shoe sole rubber particles, and 1 part of modified Petroleum resin, 1 part of linear low-density polyethylene powder, mixed for 1.5 hours at 165°C ...

Embodiment 2

[0051] The component raw materials of the emulsified modified asphalt used in Example 2 are shown in Table 3 below.

[0052] Table 3 Raw material components of emulsified modified asphalt

[0053] serial number Raw material components Content / part 1 70# matrix asphalt 40 2 rock asphalt 6 3 Modified Petroleum Resin 3 4 Linear Low Density Polyethylene Powder 1 5 Cationic Asphalt Emulsifier 0.3 6 70℃ hot water 49.7

[0054] The preparation method of the emulsified modified asphalt of this embodiment comprises the steps:

[0055] (1) Preparation of modified asphalt: Heat 40 parts of 70# base asphalt to 165 ° C, stir and keep warm properly, add 6 parts of rock asphalt, 3 parts of modified petroleum resin, and 1 part of linear low density polyethylene powder, Mix at 165°C for 1.5 hours at a stirring speed of 500r / min, keep stirring, and set aside;

[0056] (2) Preparation of soap solution: Weigh 0.3 parts of cationic aspha...

Embodiment 3

[0072] The component raw materials of the emulsified modified asphalt used in Example 3 are shown in Table 5 below.

[0073] Table 5 Raw material components of emulsified modified asphalt

[0074] serial number Raw material components Content / part 1 70# matrix asphalt 40 2 coal tar pitch 8 3 Organic bentonite 1 4 Ethylene-vinyl acetate copolymer 2 5 Linear Low Density Polyethylene Powder 1 6 Cationic Asphalt Emulsifier 0.3 7 70℃ hot water 49.7

[0075] The preparation method of the emulsified modified asphalt of this embodiment comprises the steps:

[0076] (1) Preparation of modified asphalt: Heat 40 parts of 70# base asphalt to 165 ° C, stir and keep warm properly, add 8 parts of coal tar pitch, 1 part of organic bentonite, 2 parts of ethylene-vinyl acetate copolymer, 1 part of thread Type low-density polyethylene powder, mixed at 165°C for 1.5h at a stirring speed of 500r / min, kept stirring, and set aside; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com