Electrolyte containing additive and lithium metal secondary battery

An electrolyte and additive technology, used in secondary batteries, non-aqueous electrolyte batteries, lithium batteries, etc., can solve the problems of poor battery cycle life, unstable lithium electrode interface, etc., to improve stability, cycle stability and coulombic Significant increase in efficiency and effect of improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

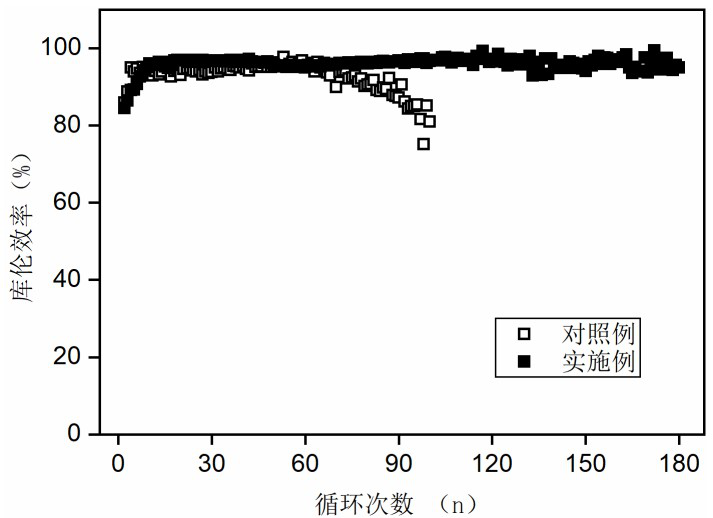

[0033] Lithium metal secondary battery electrolyte containing additives, the lithium salt is lithium bisfluorosulfonimide LiFSI, the solvent is ethylene glycol dimethyl ether DME and 1,3-dioxolane DOL, and the additive is perfluoro(2- Methyl-3-oxaacetic acid) Lithium. Its preparation method is: mix the solvent ethylene glycol dimethyl ether DME and 1,3-dioxolane DOL at a volume ratio of 1:1, and then add lithium salt lithium bisfluorosulfonimide LiFSI at a concentration of 0.7 mol / L. Finally, add additives to make the concentration 100 mmol / L. The above-mentioned additives were not included in the comparative example.

[0034] Load 2.0 mg / cm2 per unit area 2 The pole piece of lithium titanate was used as the positive electrode, and the amount of electrolyte added was 40 μL, and the charge and discharge test was carried out at a rate of 1C. The test results show that the battery using the additive-containing electrolyte still has a capacity retention rate of more than 90% ...

Embodiment 2

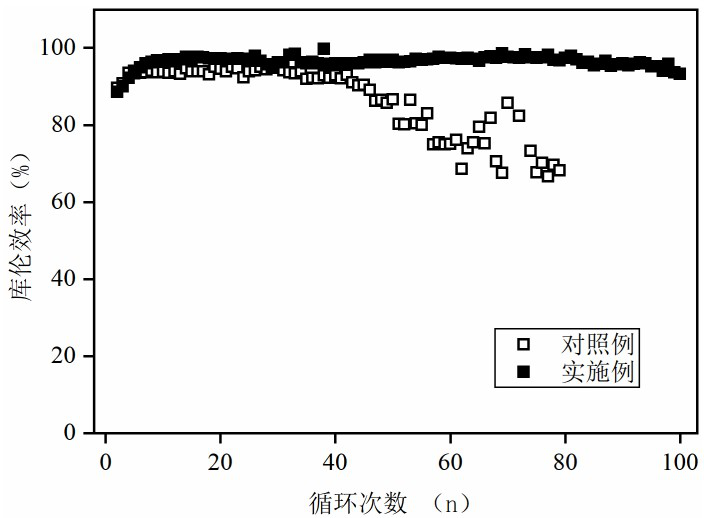

[0036] Lithium metal secondary battery electrolyte containing additives, the lithium salt is lithium bistrifluoromethanesulfonimide LiTFSI, the solvent is triglyme TEGDME and 1,3-dioxolane DOL, and the additive is perfluorinated Ammonium (2-methyl-3-oxaacetic acid). The preparation method is as follows: the solvent triethylene glycol dimethyl ether TEGDME and 1,3-dioxolane DOL are mixed at a volume ratio of 1:1, and then lithium salt LiTFSI is added to the concentration of 1.9 mol / L. Finally, add perfluoro(2-methyl-3-oxaacetic acid) ammonium additive to make the concentration 20 mmol / L. The above-mentioned additives were not included in the comparative example.

[0037] The lithium titanate loading per unit area of the positive electrode is 3.0 mg / cm 2 The electrode piece was added with 40 μL of electrolyte, and the charge and discharge test was performed at a rate of 1C. The test results show that the battery using the additive-containing electrolyte still has a capacity ...

Embodiment 3

[0039] Lithium metal secondary battery electrolyte containing additives, the lithium salt is lithium hexafluorophosphate LiPF 6 , the solvent is ethylene carbonate EC and dimethyl carbonate DMC, and the additive is lithium perfluoropropyl polydimethyl carboxylate. Its preparation method is: mix the solvent ethylene carbonate EC and dimethyl carbonate DMC at a volume ratio of 1:1, and then add lithium salt lithium hexafluorophosphate LiPF 6 , the concentration is 1.1mol / L. Finally, add perfluoropropyl lithium polydimethylcarboxylate additive to make the concentration 0.2 mol / L. The above-mentioned additives were not included in the comparative example.

[0040] The lithium titanate loading per unit area of the positive electrode is 4.6 mg / cm 2 The electrode piece was added with 40 μL of electrolyte, and the charge and discharge test was performed at a rate of 1C. The test results show that the battery using the additive-containing electrolyte still has a capacity retentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com