Bionic adhesive material-based limb bone muscle exercise device in microgravity environment

An exercise device and microgravity technology, applied in sports accessories, gymnastics equipment, etc., to achieve the effects of simple mechanism, small footprint, and slowing bone loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

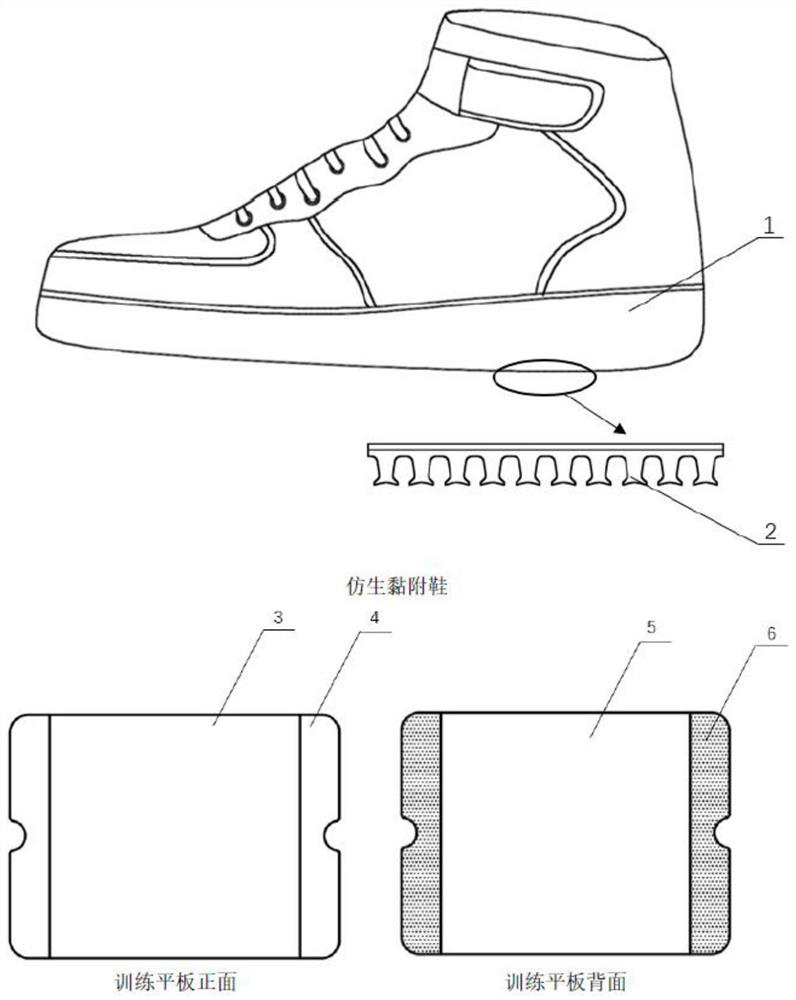

[0024] The production process of bionic adhesive shoes is as follows

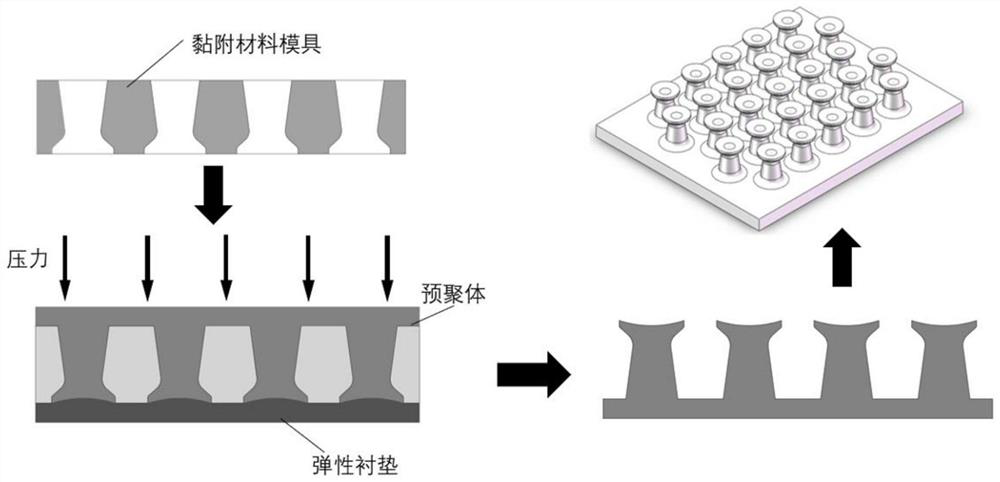

[0025] A lower limb skeletal muscle training device based on bionic adhesive materials in a microgravity environment. Bionic adhesive structure flat-press manufacturing method for through-hole nickel-based mold. Chinese invention patent. CN111993657A" discloses micro-nano imprinting technology for the preparation of adhesive materials. The preparation process can be found in figure 2 , the main steps are to place the side of the mold with the end-expanded structure on the elastic liner, and coat a uniform thermosetting silicone rubber prepolymer on the other side of the mold. The prepolymer has a tensile strength of 15Mpa and a Shore hardness of 75A, and then as for the nanoimprinting equipment, uniform pressure is applied on the upper part of the prepolymer, and the amount of depression at the end of the adhesive material is changed by adjusting the applied pressure. After the prepolymer is heated and cu...

Embodiment 2

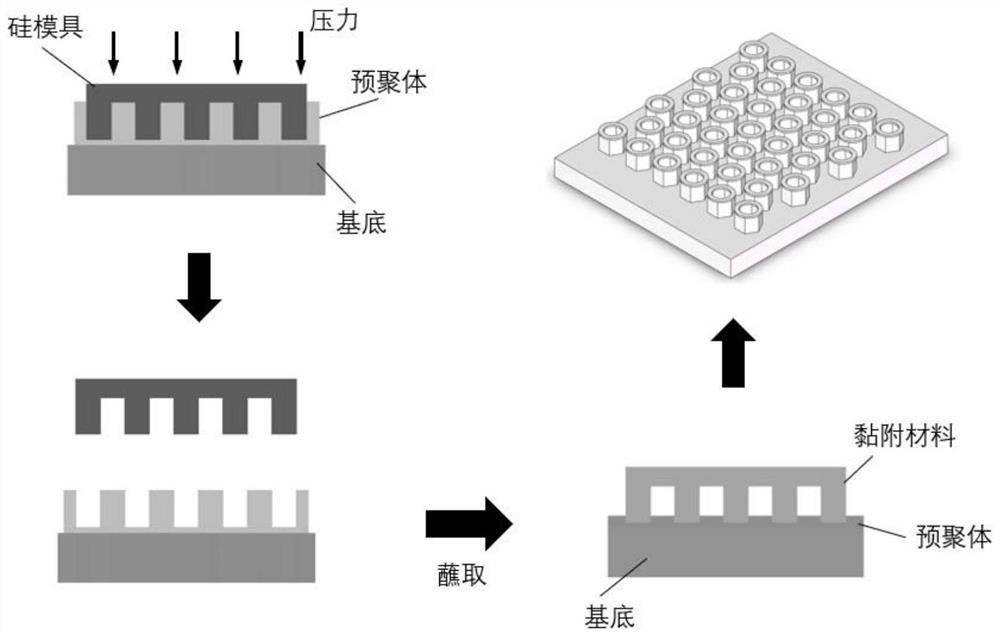

[0030] The preparation process of the biomimetic adhesive material is as follows. The polyurethane acrylate is evenly coated on the upper side of the silicon mold that has undergone anti-adhesive treatment, and then placed in the nanoimprinting equipment. After vacuuming until the air bubbles are completely eliminated, turn on the pressure, and turn on the UV light after it is completely filled. Light source, light for one minute to complete curing, demoulding to obtain hollow hexagonal prism biomimetic adhesive material. Then, the terminal expansion structure of the adhesive material was prepared by dipping. The specific method was to spin coat a layer of urethane acrylate prepolymer with a thickness of 5um on the glass sheet with a homogenizer, and then place the side of the adhesive material with the microstructure on the Spin-coat the prepolymer on the glass, let it stand for 15 seconds, place the adhesive material on the anti-adhesive silicon wafer, let it stand for 8 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com