Application of microporous carbon material in adsorption separation of olefin and alkane

A technology of adsorption separation and microporous carbon, which is applied in the field of application of microporous carbon materials in the adsorption and separation of alkenes and alkanes, can solve the problem of difficult to meet the strict requirements of gas dynamic separation with similar structure, unfavorable adsorption and separation selectivity, carbon materials Wide pore size and other issues, to achieve the effect of green preparation method, high kinetic adsorption selectivity, and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

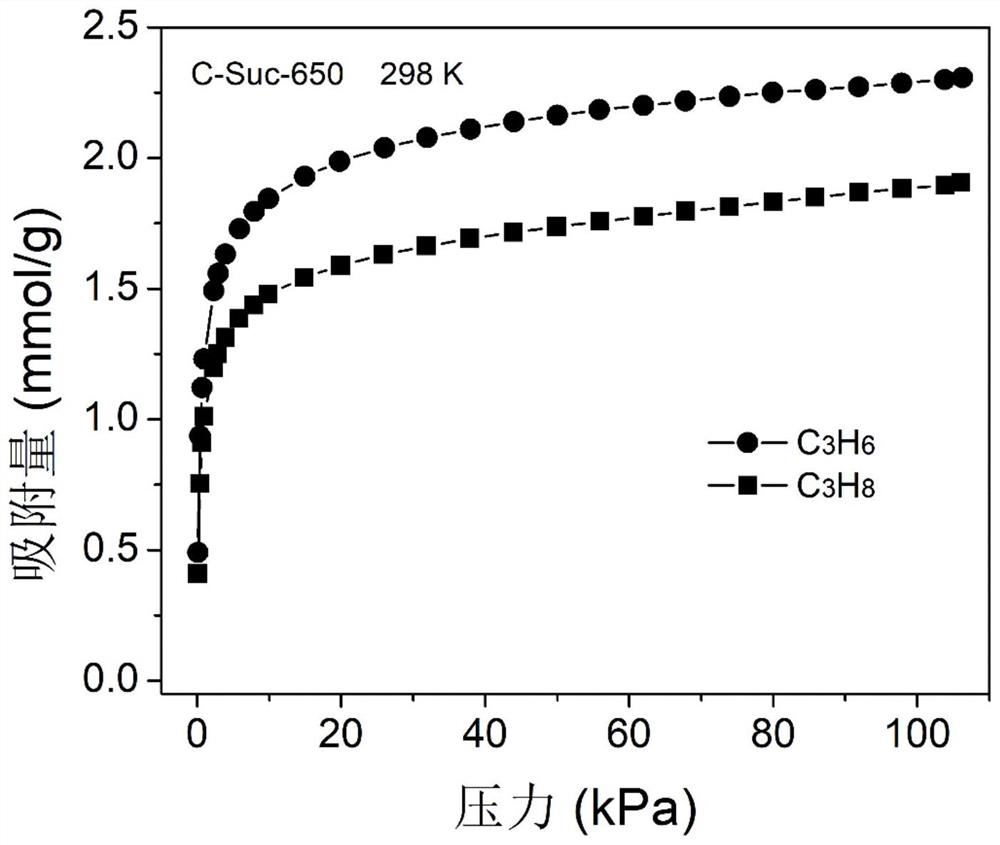

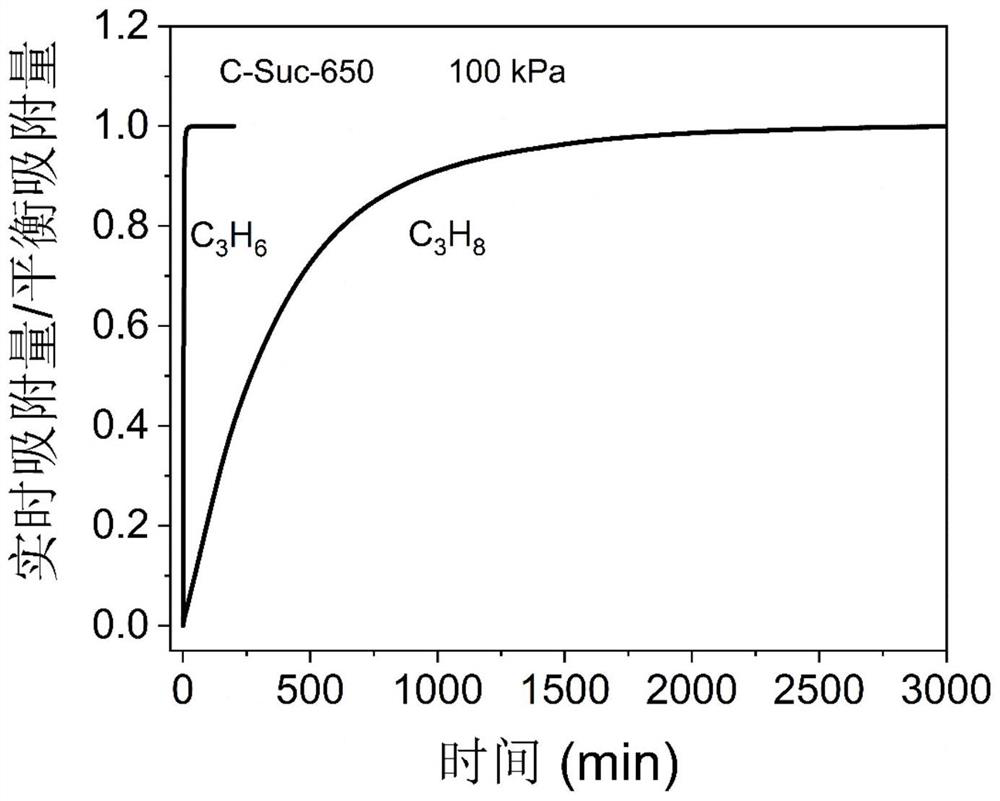

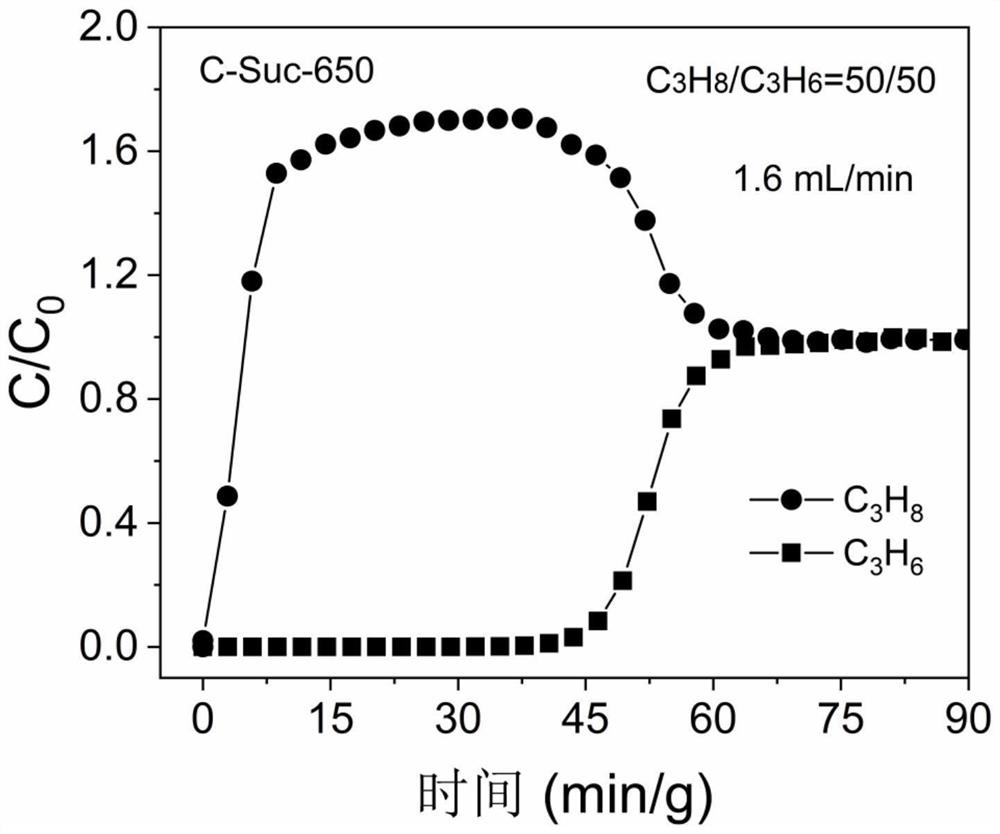

[0050] Prepare a 0.75mol / L sucrose solution, fill the sucrose solution to 90% of the hydrothermal reactor, place it in a temperature-programmed oven, and raise the temperature to 190°C at a rate of 3°C / min to react for 5 hours, and then the obtained char is directly Dry and grind the tablet, transfer it to a tube furnace, in a nitrogen gas atmosphere, control the nitrogen flow rate to 25mL / min, raise the temperature to 500°C at a rate of 1°C / min, and then rise to 500°C at a rate of 5°C / min. 650°C for high-temperature activation to form pores, and after reaching the target temperature, directly cool down to prepare microporous carbon materials.

[0051] The microporous carbon material prepared in this example has a microporosity of 100% and a specific surface area of 466m 2 / g, the effective micropore diameter is

[0052] In order to test the adsorption performance of the microporous carbon material prepared in this example, a single-component adsorption experiment of prop...

Embodiment 2

[0056] Prepare a 0.75mol / L sucrose solution, fill the sucrose solution to 90% of the hydrothermal reactor, place it in a temperature-programmed oven, and raise the temperature to 190°C at a rate of 3°C / min to react for 5 hours, and then the obtained char is directly Dry and grind the tablet, transfer it to a tube furnace, in a nitrogen gas atmosphere, control the nitrogen flow rate to 25mL / min, raise the temperature to 500°C at a rate of 1°C / min, and then rise to 500°C at a rate of 5°C / min. 750°C for high temperature activation pore formation. After reaching the target temperature, the temperature is directly lowered and cooled to prepare a microporous carbon material.

[0057] The microporous carbon material prepared in this example has a microporosity of 100% and a specific surface area of 536m 2 / g, the effective micropore diameter is

[0058] In order to test the adsorption performance of the microporous carbon material prepared in this example, a single-component ad...

Embodiment 3

[0062]Prepare a 0.5mol / L sucrose solution, fill the sucrose solution to 90% of the hydrothermal reactor, place it in a temperature-programmed oven, and raise the temperature to 190°C at a rate of 3°C / min to react for 5 hours, and then the obtained char is directly Dry and grind the tablet, transfer it to a tube furnace, in a nitrogen gas atmosphere, control the nitrogen flow rate to 25mL / min, raise the temperature to 500°C at a rate of 1°C / min, and then rise to 500°C at a rate of 5°C / min. 650°C for high temperature activation pore formation. After reaching the target temperature, the temperature is directly lowered and cooled to prepare a microporous carbon material.

[0063] The microporous carbon material prepared in this example has a microporosity of 100% and a specific surface area of 495m 2 / g, the effective micropore diameter is

[0064] The same method as in Example 1 was used to carry out the single-component adsorption experiment of propylene and propane. Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com