Method for extracting peony flower essential oil

A technology of peony essential oil and extraction method, which is applied in the direction of essential oil/fragrance, fat production, etc., can solve the problems of poor wall breaking effect and difficulty in obtaining extraction rate, so as to improve exudation efficiency, safe and controllable extraction process, The effect of less amount of extractant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: prepare the solid alkali of different proportioning

[0034] Get magnesium chloride, calcium chloride, add 10 times the water of calcium chloride weight, stir evenly, be mixed with aqueous solution; Add graphite powder (cross 100 mesh sieves) and stir evenly; Then add dropwise lye (mass fraction 10% while stirring) % NaOH solution) to adjust the pH value to 12 for precipitation, filter, and separate the precipitate; wash the precipitate with deionized water, dry it in the air, and then place it in a muffle furnace for calcination at 900° C. for 36 hours to obtain a solid base.

[0035] The consumption of magnesium chloride, calcium chloride, water, graphite powder is shown in Table 1.

[0036] Table 1 prepares the consumption of each component of solid alkali

[0037] Sample serial number Magnesium chloride (hexahydrate) calcium chloride graphite powder solid base 1 — 111g 444g Solid base 2 203g — 444g Solid base 3 203...

Embodiment 2

[0038] Embodiment 2: the influence of the solid alkali of different proportioning on the extraction rate of essential oil

[0039] Refer to the following steps to extract peony essential oil, set blank example and test example, compare the influence of different conditions such as not adding alkali (blank example), adding different solid alkalis (test example) prepared in Example 1 on the extraction rate of peony essential oil.

[0040] The extraction steps of the blank example are:

[0041] (1) Take 1 kg of peony petals, add 3 kg of water to mix, and beat to obtain a beating mixture; stand for 3 hours;

[0042](2) Transfer the beating mixture into the still, add 11kg of water, make the total weight of the slurry reach 15 times the weight of the peony petals, and carry out steam distillation: first stir the still to heat up to 60°C within 30 minutes, and keep it warm for 30 minutes; Continue stirring and heating for 20 minutes to raise the temperature to 80°C and keep it warm...

Embodiment 3

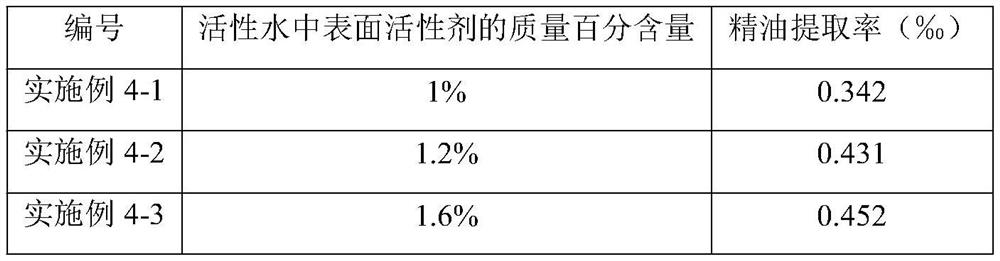

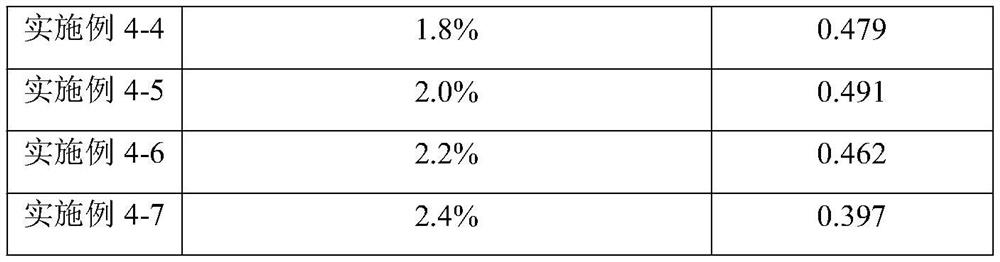

[0051] Embodiment 3: the impact of surfactants in different proportions on the extraction rate of essential oils

[0052] Refer to the following method to extract peony essential oil:

[0053] (1) Get the peony petals of 1kg, add 3kg active water and mix, beating, obtain beating mixture; Described active water is the aqueous solution of surfactant;

[0054] (2) Add 200 g of solid alkali 7 to the beating mixture, and add 3 kg of water, stir evenly and let stand for 3 hours to obtain a mixed slurry;

[0055] (3) transfer the mixed slurry obtained in step (2) into the distillation still, add 8kg of water again, make the total weight of the slurry reach 15 times the weight of the peony petals, and carry out steam distillation: first make the still within 30min Stir and heat up to 60°C, keep warm for 30min; continue stirring and heating for 20min to raise the temperature to 80°C, keep warm for 3h; then heat up for 10min until the liquid boils and start distillation, the distillati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com