Cleaning agent for condenser and radiator of automobile air conditioner as well as preparation method and application of cleaning agent

A technology for automobile air conditioners and cleaning agents, applied in the field of cleaning agents, can solve problems such as cleaning pollution, and achieve the effects of enhancing anti-corrosion ability, super fast-drying ability, and ultra-clean cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

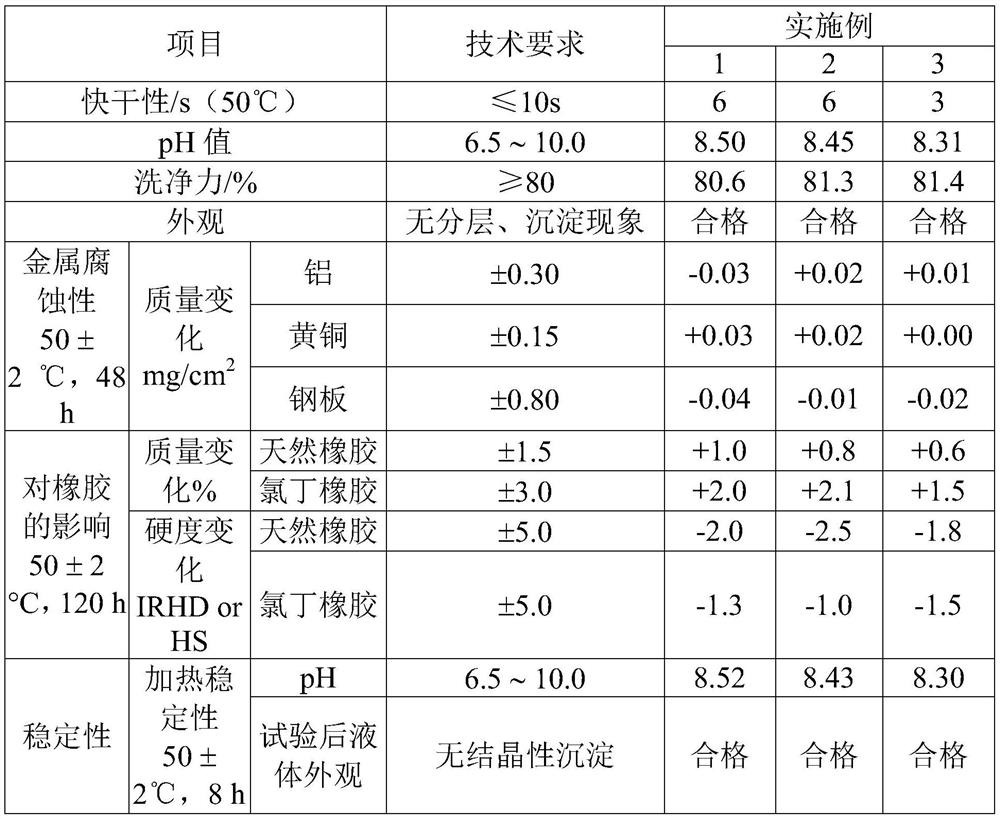

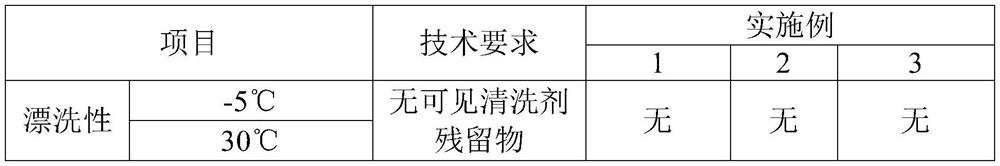

Examples

Embodiment approach

[0052] According to a particularly preferred embodiment of the present invention, the composition contains the following components by weight:

[0053] Ethanol: 30-40 parts by weight;

[0054] Polyol: 0.2-0.4 parts by weight;

[0055] 0.1-0.2 parts by weight of composite surfactant;

[0056] Tolyl benzotriazole: 0.1-0.3 parts by weight;

[0057] 6-amino-2-mercaptobenzothiazole: 0.1-0.3 parts by weight

[0058] Triethanolamine phosphate composition: 0.4-0.6 parts by weight;

[0059] Oleic acid or oleate: 0.1-0.3 parts by weight;

[0060] Benzoic acid or benzoate: 0.7-0.9 parts by weight;

[0061] Citric acid or citrate: 0.1-0.3 parts by weight;

[0062] Bactericide: 0.1-0.3 parts by weight;

[0063] Benzyl ammonium benzoate amide: 0.0001-0.0005 parts by weight;

[0064] Sodium metasilicate hydrate: 0.6-0.8 parts by weight;

[0065] Anti-scaling agent: 0.4-0.6 parts by weight;

[0066] Potassium hydroxide: set amount;

[0067] Water: 60-70 parts by weight;

[0068] W...

Embodiment 1

[0103] In 1500kg reactor, add 750kg water and 3kg glycerin, stir and mix under the stirring rate of 60rpm / min, be warming up to 50 ℃, compound surfactant (1.5kg of C 12 Perfluoroalkyl betaine and 4kg cocamidopropyl betaine) 5.5kg input, after stirring, add 1kg oleic acid, 1.2kg citric acid, 1.5kg tolyl benzotriazole, 1.2kg of 6 -Amino-2-mercaptobenzothiazole, 1.4kg triethanolamine phosphate composition, 12kg sodium benzoate, then add potassium hydroxide to adjust the pH value to 8.1, 1kg ethylparaben, 0.001kg benzyl ammonium amide, 5kg Sodium polyacrylate, finally add 20kg of sodium metasilicate nonahydrate solution dissolved in water at 80°C (wherein, the water is 14kg, and sodium metasilicate nonahydrate is 6kg), stir and dissolve, then cool down to room temperature and add 210kg of ethanol, fully After stirring for 30 minutes, take a sample to test the pH value. If the pH value is between 8 and 9, it is qualified. After passing the test, it is filled through a 5 μm filter. ...

Embodiment 2

[0105] Add 500kg water and 1kg glycerin in 1500kg reactor, stir and mix under the stirring rate of 60rpm / min, be warming up to 50 ℃, compound surfactant (1kg of C 12 Perfluoroalkyl betaine and 4kg alkyl (cocamidopropyl betaine) 5kg input, after stirring, add 3kg oleic acid, 3kg citric acid, 5kg methyl benzotriazole, 4kg of 6-amino -2-Mercaptobenzothiazole, 1.2kg triethanolamine phosphate ester composition, 10kg sodium benzoate, after stirring evenly, add potassium hydroxide to adjust the pH value to 8.0, then add 2kg methylparaben, 0.0015kg benzyl ammonium amide , 6kg tetrasodium EDTA, stir evenly and add 20kg of sodium metasilicate nonahydrate dissolved in water at 80°C (among them, water is 13.5kg, sodium metasilicate nonahydrate is 6.5kg), stir and dissolve, and then cool to room temperature and add 450kg of ethanol, after fully stirring for 30 minutes, take a sample to test the pH value. If the pH value is between 8-9, it is qualified. After passing the pass, it will be fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com