PGMA copolymer microsphere-polyethyleneimine coating modified polymer film and preparation method thereof

A polyethyleneimine, polymer membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as inability to achieve surface morphology, uncontrollable microsphere process, and non-uniformity of microspheres. , to achieve the effect of excellent hydrophilicity and anti-pollution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

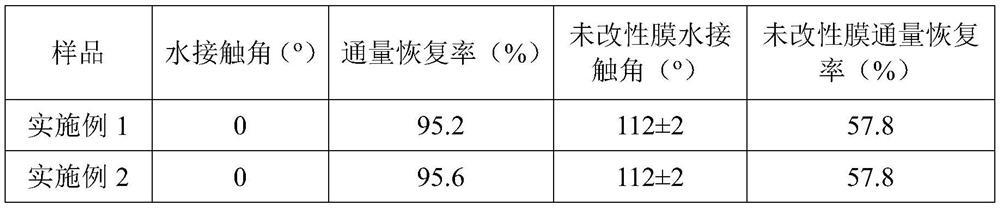

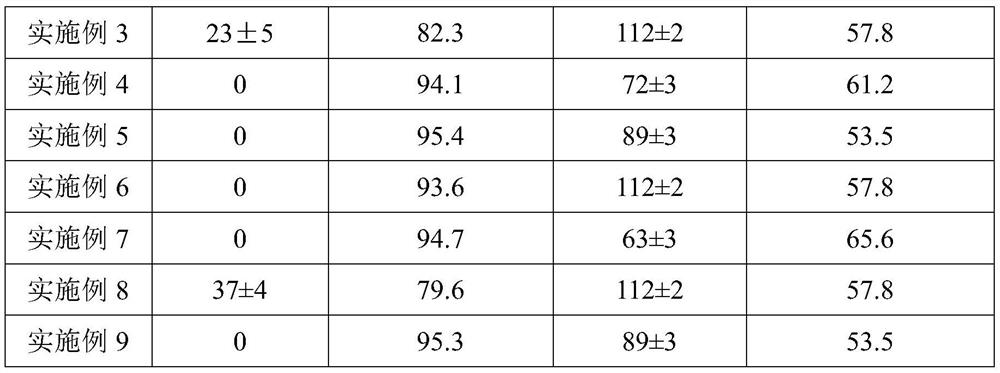

Examples

Embodiment 1

[0026] A method for PGMA copolymerized microspheres-polyethyleneimine coating modified PVDF film, comprising the following steps:

[0027] (1) Put 7.5g of PVP K-30 into a three-necked flask equipped with a stirring device, add 15g of absolute ethanol and 2.5g of GMA, under stirring conditions, pass argon for 30 minutes until the solid is completely dissolved, then add 2.5g of GMA and 0.025g AIBN; Stir the reaction in an oil bath at 70°C under argon atmosphere for 6h, add 22.9uL DVB under argon atmosphere, continue to react under argon atmosphere for 18h, then terminate the reaction, centrifuge the reaction solution, and use 95% ethanol Disperse, continue to precipitate, disperse and wash for 3 times, and finally the product is dispersed in deionized water for later use; the particle size of the obtained PGMA-containing microspheres is about 350nm; the obtained PGMA copolymerized microsphere dispersion is further diluted with deionized water and dispersed to a concentration of 3...

Embodiment 2

[0031] A method for PGMA copolymerized microspheres-polyethyleneimine coating modified PVDF film, comprising the following steps:

[0032] (1) Adopt the PGMA copolymerization microsphere preparation method in step 1 in the embodiment 1 to prepare PGMA copolymerization microspheres, adjust DVB add-on to be 7.6uL; PGMA copolymerization microsphere particle diameter 1650nm; Gained PGMA copolymerization microsphere dispersion liquid continues to add Dilute and disperse with ionic water to form a PGMA copolymerized microsphere aqueous dispersion with a mass percent concentration of 3% (wt%);

[0033] (2) Dissolving polyethyleneimine (with a weight average molecular weight of 25000 g / mol) in deionized water to prepare an aqueous solution of polyethyleneimine with a mass percent concentration of 5% (wt%);

[0034] (3) 3% (wt%) PGMA copolymerized microsphere aqueous dispersion and polyethyleneimine aqueous solution alternately sprayed (utilizing a spray gun or other spray equipment) i...

Embodiment 3

[0036] A method for PGMA copolymerized microspheres-polyethyleneimine coating modified PVDF film, comprising the following steps:

[0037] (1) Add 0.5g of glycidyl methacrylate (GMA), 1.975g of styrene (St), 0.025g of divinylbenzene (DVB), and 40g of deionized water into a three-necked flask. / min and stir for 30 minutes until completely dissolved; put it into a 70°C oil bath under the condition of argon; dissolve 0.075g of potassium persulfate in 7.5g of deionized water, and add the above solution under the condition of argon. The reaction system was stirred continuously for 24 hours to terminate the reaction; the reaction liquid was centrifuged and precipitated, dispersed with 95% ethanol, and the precipitate was dispersed and washed for 3 times, and the final product was dispersed in deionized water for later use; the particle diameter of the obtained PGMA copolymerized microspheres was 100 nm; the obtained PGMA copolymerized microspheres The dispersion liquid continues to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com