Preparation method of alkyne-rich C4 fraction selective hydrogenation catalyst

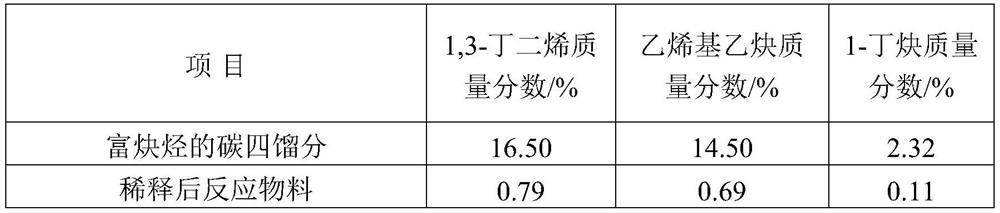

An alkyne-rich carbon four fraction, selective hydrogenation technology, applied in catalyst activation/preparation, hydrogenation to hydrocarbons, hydrocarbons, etc., can solve problems such as cost increase, catalyst activity decrease, selectivity decrease, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

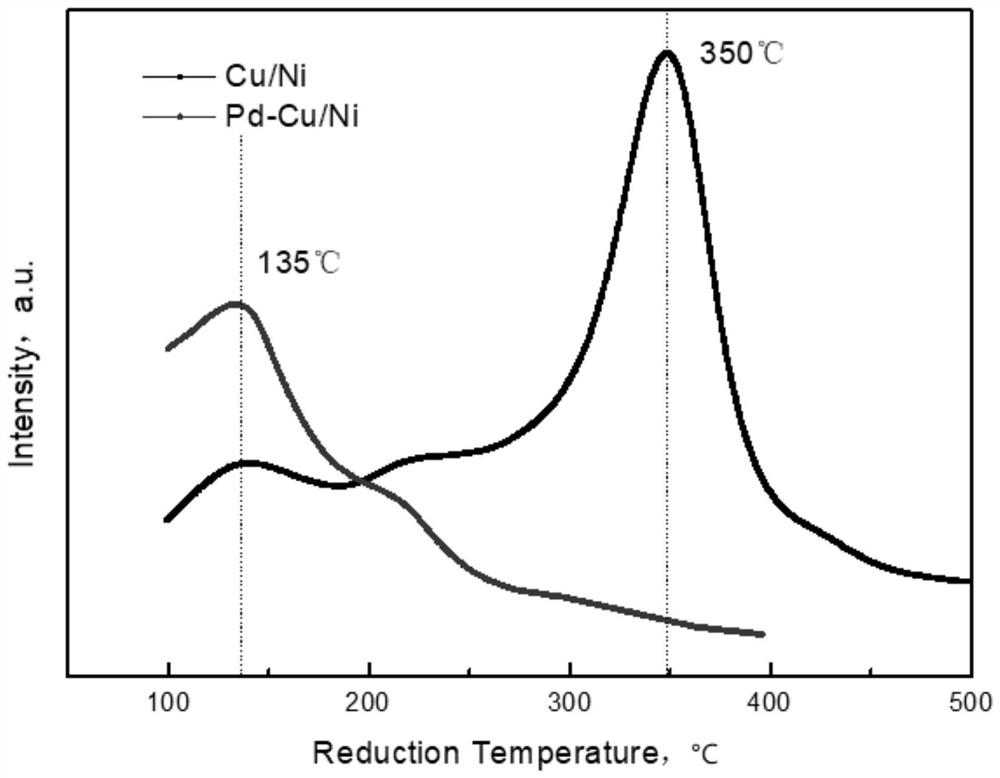

AI Technical Summary

Problems solved by technology

Method used

Image

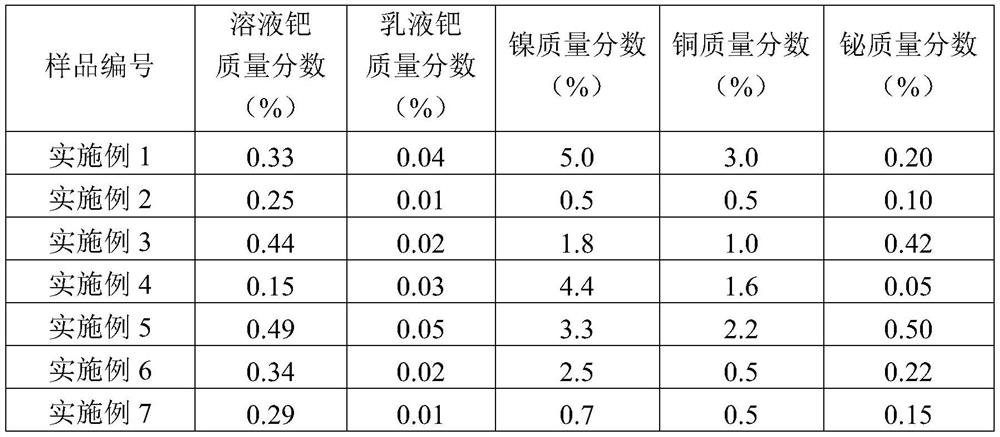

Examples

Embodiment 1

[0036] Catalyst carrier preparation: commercially available bimodal pore distribution spherical alumina carrier with a diameter of 3mm is used. After calcination at 1100°C for 4 hours, the pore size distribution ranges are 20-45nm and 90-400nm respectively, and the specific surface area is 43m 2 / g, weigh the carrier 100g.

[0037] Catalyst preparation:

[0038] (1) Palladium chloride is prepared as an active component impregnation solution, and the pH is adjusted to 1.7, and then the carrier is added to the Pd salt solution, after impregnation and adsorption for 2 hours, dried at 100°C for 4 hours, and roasted at 550°C for 2 hours to obtain a semi-finished catalyst C1-A.

[0039] (2) Bismuth nitrate is completely dissolved into the impregnating solution, impregnated with equal volume, impregnated the semi-finished catalyst C1-A in the prepared solution, shaken evenly, precipitated for 0.5h, dried at 100°C for 2h, and roasted at 400°C for 6h to obtain Semi-finished catalyst ...

Embodiment 2

[0048] Catalyst carrier preparation: commercially available bimodal pore distribution spherical alumina carrier with a diameter of 3mm is used. After calcination at 1050°C for 4 hours, the pore size distribution ranges are 14-45nm and 85-350nm respectively, and the specific surface area is 60m 2 / g, weigh the carrier 100g.

[0049] Catalyst preparation:

[0050] (1) Dissolve nickel nitrate and copper nitrate in 80g of water, add 40g of n-pentane, 20g of cetyltrimethylammonium bromide, and 20g of n-hexanol to fully stir to form a microemulsion, and add the carrier to the prepared microemulsion After soaking for 0.5h, the remaining liquid was filtered off and washed with deionized water until neutral. Dry at 60°C for 6h and calcinate at 590°C for 2h to prepare semi-finished catalyst C2-A.

[0051] (2) Palladium chloride was dissolved in 80 g of water, 40 g of n-pentane, 20 g of cetyltrimethylammonium bromide, and 20 g of n-hexanol were added and fully stirred to form a microem...

Embodiment 3

[0060] Catalyst carrier preparation: commercially available bimodal pore distribution spherical alumina carrier with a diameter of 3-4mm is used. After calcination at 1120°C for 4 hours, the pore size distribution ranges are 30-45nm and 100-500nm respectively, and the specific surface area is 25m 2 / g, weigh the carrier 100g.

[0061] Catalyst preparation:

[0062] (1) nickel nitrate, copper nitrate are dissolved in 70g water, add 35g n-hexane, 17g tween80, 17g n-amyl alcohol and fully stir to form a microemulsion, add the carrier to the prepared microemulsion and soak for 2h, filter the remaining liquid, Wash with deionized water until neutral. Dry at 80°C for 5h, and calcinate at 500°C for 3h to prepare semi-finished catalyst C3-A.

[0063] (2) Palladium chloride is formulated into the active component impregnating solution, and the pH is adjusted to be 2.5, and the semi-finished catalyst C3-A prepared in step (1) is added in the salt solution of Pd, after impregnating and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com