Protein gypsum retarder and preparation method thereof

A gypsum retarder and protein technology, applied in the field of building material admixtures, can solve problems such as easy moisture absorption, and achieve the effects of speeding up the reaction speed, improving the retarding effect and improving the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

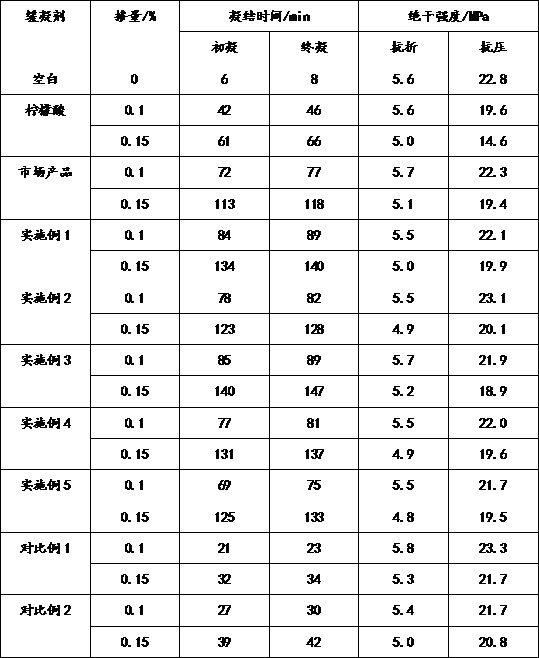

Examples

preparation example Construction

[0022] A kind of preparation method of proteinaceous gypsum retarder provided by the invention comprises the following steps:

[0023] Pretreatment of protein components: Add 100-120 parts by mass of water into the first reaction kettle, then add 20-30 parts by mass of alkali, stir until completely dissolved to form an alkali solution, and then heat the temperature of the alkali solution to 80 At ~90°C, add 65-80 parts by mass of the protein component into the alkaline solution, continue stirring for 2-3 hours, and cool to room temperature to obtain the protein solution;

[0024] Wherein, the protein component is soybean protein isolate, industrial grade bone glue or gelatin, and soybean protein isolate has high protein content and is rich in various amino acids. Both bone glue and gelatin are processed from animal protein and are widely used in printing and food processing respectively. Both bone glue and gelatin are rich in animal protein, and after hydrolysis, different ki...

Embodiment 1

[0033] A preparation method of protein gypsum retarder, the specific preparation method includes the following steps, the following components are added in parts by mass:

[0034] (1) Pretreatment of protein components: Add 100 parts of water into the first reaction kettle, and then add 20 parts of flaked sodium hydroxide, stir until completely dissolved, and form an alkaline solution. Heat the temperature of the solution to 90°C, add 65 parts of soybean protein isolate into the alkaline solution, keep stirring for 2 hours, and cool to room temperature to obtain a protein solution.

[0035] (2) Preparation of mixed solution: Add 35 parts of citric acid into the protein solution, stir well until completely dissolved, and cool to room temperature.

[0036] (3) Preparation of powder retarder: Add 50 parts of quicklime and 100 parts of diatomaceous earth into the second reaction kettle, open the outlet valve, and heat to 160°C while stirring. The second reaction kettle continues ...

Embodiment 2

[0038] A proteinaceous gypsum retarder and its preparation method. The specific preparation method includes the following steps, and the following components are added in parts by mass:

[0039] (1) Pretreatment of protein components: Add 120 parts of water into the first reaction kettle, and then add 30 parts of flake sodium hydroxide, stir until completely dissolved, and form an alkaline solution. Heat the temperature of the solution to 80°C, add 80 parts of soybean protein isolate into the alkaline solution, keep stirring for 3 hours, and cool to room temperature to obtain a protein solution.

[0040] (2) Preparation of mixed liquid: Add 20 parts of citric acid into the protein liquid, stir well until completely dissolved, and cool to room temperature.

[0041](3) Preparation of powder retarder: Add 30 parts of quicklime and 120 parts of diatomaceous earth into the second reaction kettle, open the outlet valve, and heat to 160°C while stirring. The second reaction kettle c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com