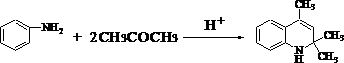

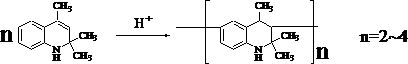

Method for purifying 2, 2, 4-trimethyl-1, 2-dihydroquinoline polymer

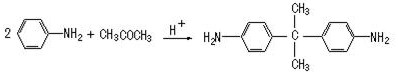

A technology of dihydroquinoline and trimethyl, applied in the direction of organic chemistry, etc., can solve the problems of high content of primary amine and no quantitative intermediate control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 100 grams of 2,2,4-trimethyl-1,2-dihydroquinoline polymer (containing 6% of primary amine) and 300 grams of toluene to the reactor, stir until a uniform solution is formed, then heat up, Add 3.5g (purity 90%) formic acid and 50g benzene mixed solution dropwise to the reactor under stirring at 80-90°C, the dropwise addition time is 30 minutes, after the addition is complete, raise the reaction temperature to 110-120°C and maintain The reaction was stirred for 120 minutes, and the water generated by the reaction was azeotropically removed by the solvent. After the reaction was completed, 50 grams of 0.1% sodium hydroxide solution was added to neutralize the unreacted formic acid, the water layer was separated, and the solvent was distilled off to obtain the finished product. Analysis and detection of primary amine content was 3ppm.

Embodiment 2

[0034] Other conditions are the same as in Example 1, except that the amount of formic acid added is 3.0 grams, and the primary amine content is 41 ppm after testing.

Embodiment 3

[0036] Other conditions were the same as in Example 1, except that 4.1 grams of 99.5% acetic acid was used instead of formic acid. After testing, the primary amine content was 10 ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com