Method for purifying triglycidyl isocyanurate

A technology of glycidyl ester and triglycidyl isocyanurate, which is applied in the field of purification of triglycidyl isocyanurate, can solve the problem of TGIC yield decline, high chlorine content of TGIC products, and the inability to completely avoid the residual sodium chloride salt in the by-product and other issues to achieve good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

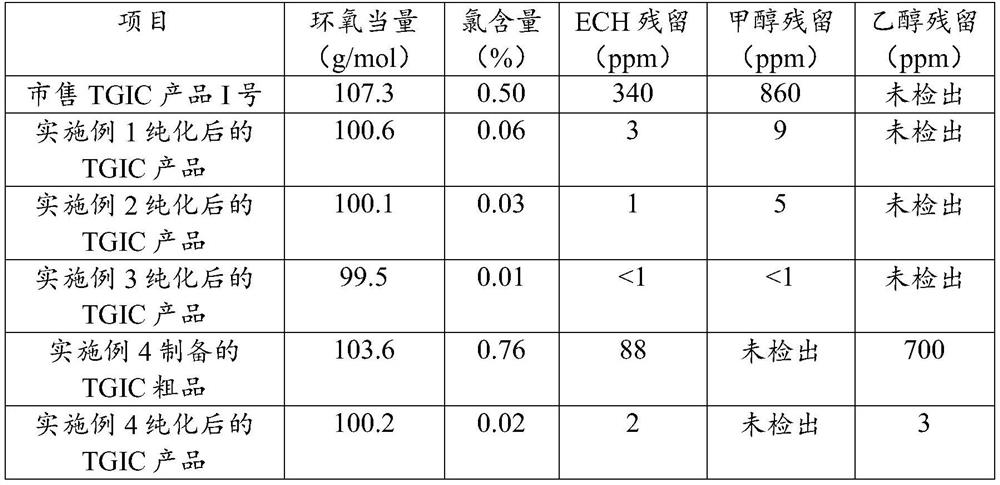

[0034] The purification method of triglycidyl isocyanurate TGIC of the present embodiment comprises the following steps: a) Take 100.66 grams of commercially available TGIC product No. Heating speed to 95°C, keep warm for 30min; b) Add 70g of water at 25°C to the flask with distillation recovery solvent system, heat to boiling, distill 10g of water, triglycidyl isocyanurate TGIC crude product is dissolved in water to form a homogeneous mixed solution; c) cool the homogeneous mixed solution to 30°C at a cooling rate of 4°C / min, and crystals are precipitated; d) filter the crystals, and then wash them with 10 grams of deionized water to obtain washed crystals e) The cleaned crystals were heated and dried under vacuum at -0.05MPa and 80°C to obtain 99.16 grams of purified TGIC product with a yield of 98.5%. The product quality analysis and characterization results are shown in Table 1.

Embodiment 2

[0036] The purification method of triglycidyl isocyanurate TGIC of the present embodiment comprises the following steps: a) Take 180.89 grams of commercially available TGIC product No. Heating speed to 100°C, and keeping it warm for 40min; b) Add 200 grams of water at 85°C to a flask with a distillation recovery solvent system, heat to boiling, distill 20 grams of water, and dissolve the crude triglycidyl isocyanurate TGIC Form a homogeneous mixed solution in water; c) cool the homogeneous mixed solution to 20° C. at a cooling rate of 3° C. / min, and crystals are precipitated; d) filter the crystals, and then wash them with 30 grams of deionized water to obtain the washed Crystals; e) The cleaned crystals were heated and dried under vacuum at -0.08MPa and 70°C to obtain 176.45 grams of purified TGIC product with a yield of 97.5%. The product quality analysis and characterization results are shown in Table 1.

Embodiment 3

[0038] The purification method of triglycidyl isocyanurate TGIC of the present embodiment comprises the following steps: a) take commercially available TGIC product No. 2056.8 grams, join in the reactor with distillation recovery solvent system, with 4 DEG C / min Heat up to 95°C at a heating rate and keep it warm for 60 minutes; b) Add 3,500 grams of water at 95°C to a reaction kettle with a distillation recovery solvent system, heat to boiling, and steam 400 grams of water, triglycidyl isocyanurate TGIC The crude product is dissolved in water to form a homogeneous mixed solution; c) the homogeneous mixed solution is cooled to 10°C at a cooling rate of 2°C / min, and crystals are precipitated; d) the crystals are filtered, and then washed with 500 grams of deionized water to obtain a clean The cleaned crystals; e) The cleaned crystals were heated and dried under vacuum at -0.095MPa and 50°C to obtain 1974.5 grams of purified TGIC product with a yield of 96.0%. The product quality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com