Microcarrier for three-dimensional culture of cells as well as preparation method and application of microcarrier

A three-dimensional culture and microcarrier technology, applied in biochemical equipment and methods, tissue culture, microorganisms, etc., can solve the problems of poor cell adhesion, cumbersome processing steps, incomplete separation, etc., and achieve biocompatibility and cell adhesion. Good adhesion, cost reduction, and avoidance of high cell seeding density requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

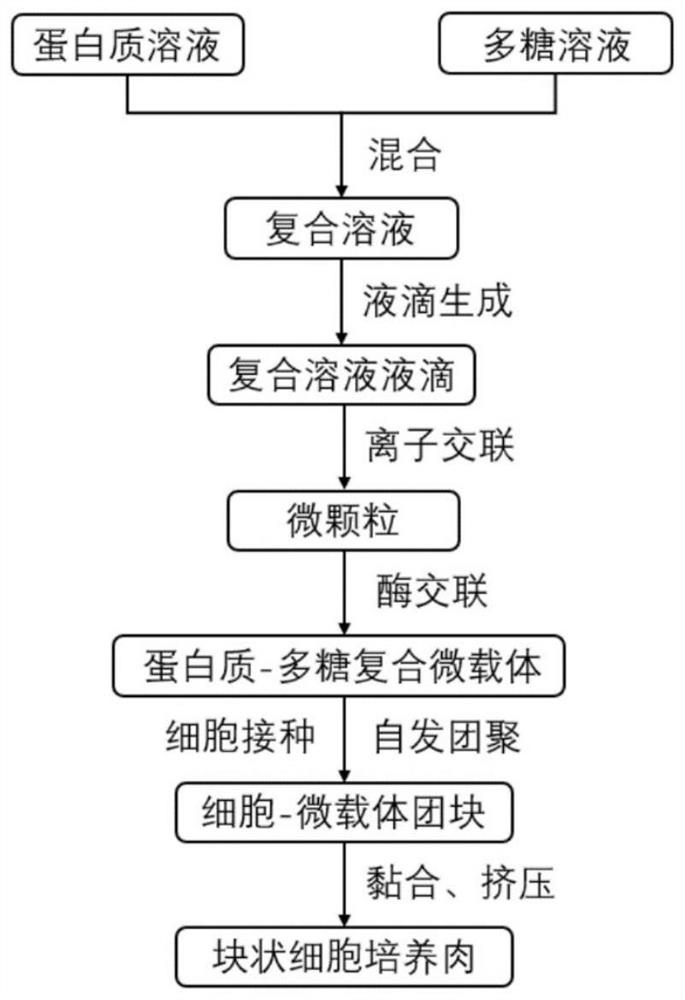

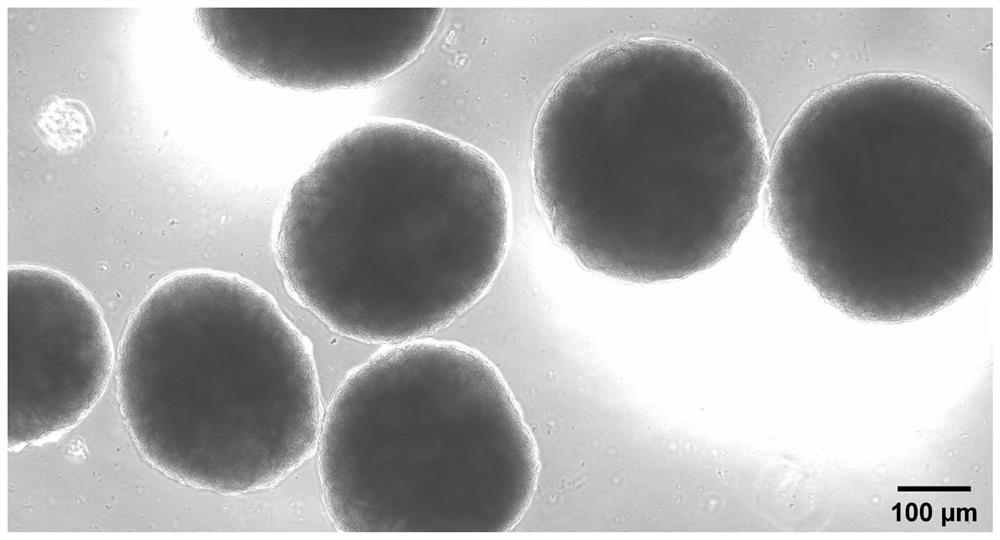

[0049] The invention provides a microcarrier for three-dimensional cell culture and a preparation method thereof, the method comprising: directly mixing edible plant-derived ion-crosslinked gel-type polysaccharides and edible non-animal-derived proteins , make a mixed liquid, generate liquid droplets, and prepare microcarriers through appropriate cross-linking and immobilization reaction conditions. The microcarrier is used for cell culture, can support the rapid proliferation of cells, and through the interaction between cells, spontaneously aggregate to form cell-microcarrier clumps. According to the needs of the actual product form, the cells can be harvested by dissolving the microcarriers for subsequent processing, or the cell culture meat products can be obtained directly by bonding and extruding the agglomerates. The microcarrier prepared by the method of the invention is used in the cell culture meat, and the operation is fast and simple, and it is easy to realize larg...

Embodiment 1

[0108] Embodiment 1: Preparation of soybean protein isolate-sodium alginate / polylysine surface modified microcarrier

[0109] Weigh 1 g of sodium alginate and add it into 100 ml of deionized water, stir at room temperature until completely dissolved, and prepare a sodium alginate solution with a concentration of 1%. Weigh 0.1 g of edible soda ash and add it to 100 ml of deionized water, stir to dissolve, then weigh 5 g of soybean protein isolate solid, add it to the alkali solution, stir at room temperature until completely dissolved, and prepare a soybean protein isolate solution with a concentration of 5%. Measure 20ml concentration of 1% sodium alginate solution, measure 80ml concentration mass volume percent concentration (g / mL) of 5% soybean protein isolate solution, mix the two solutions uniformly, and prepare sodium alginate concentration of 0.2% and 4% soy protein isolate compound solution, the mass ratio of soy protein isolate to sodium alginate is 20:1. Micro-drople...

Embodiment 2

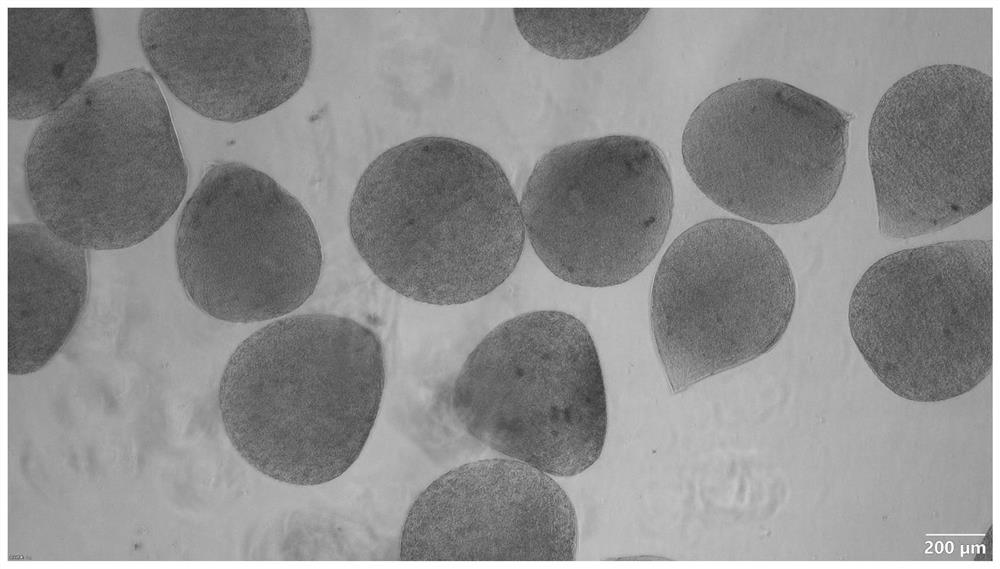

[0110] Embodiment 2: the preparation of yeast protein-low ester pectin microcarrier

[0111] Weigh 2 g of low-ester pectin and add it into 100 ml of deionized water, heat in a water bath at 60° C. and stir until completely dissolved, and prepare a low-ester pectin solution with a concentration of 2%. Weigh 5g of solid yeast protein and add it to 100ml of 2% low-ester pectin solution, stir to disperse the solid particles evenly, and the mass ratio of yeast protein to low-ester pectin is 2.5:1. Weigh 25 g of calcium chloride solid and add it into 500 ml of deionized water to form a 5% calcium chloride solution, which is used as a collection bath. Micro-droplets were prepared by electrostatic spraying, and the generated micro-droplets were cross-linked and fixed in a collection bath at room temperature for 30 minutes to obtain ion-crosslinked polysaccharide-protein composite microcarriers with a particle size of 200-800 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com