Etching solution and application thereof

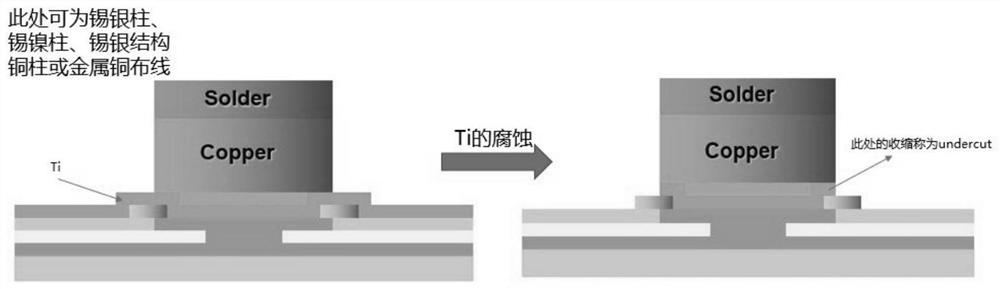

A technology of etching solution and stabilizer, which is applied in the field of etching solution and its application in the etching of titanium-based metals, can solve the problems of affecting chip reliability, aluminum electrode damage, and undercut easily, so as to maintain the stability of etching rate, The effect of long service life and avoiding excessive decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The present invention does not specifically limit the preparation method of the etching solution, which can be prepared by mixing and other methods.

[0055] The second aspect of the present invention provides an application of the above-mentioned etching solution in the etching of titanium-based metals. The titanium-based metals in the present invention can be titanium metal or titanium-containing alloy materials, such as titanium-tungsten alloys and other titanium-based metal materials used for advanced packaging.

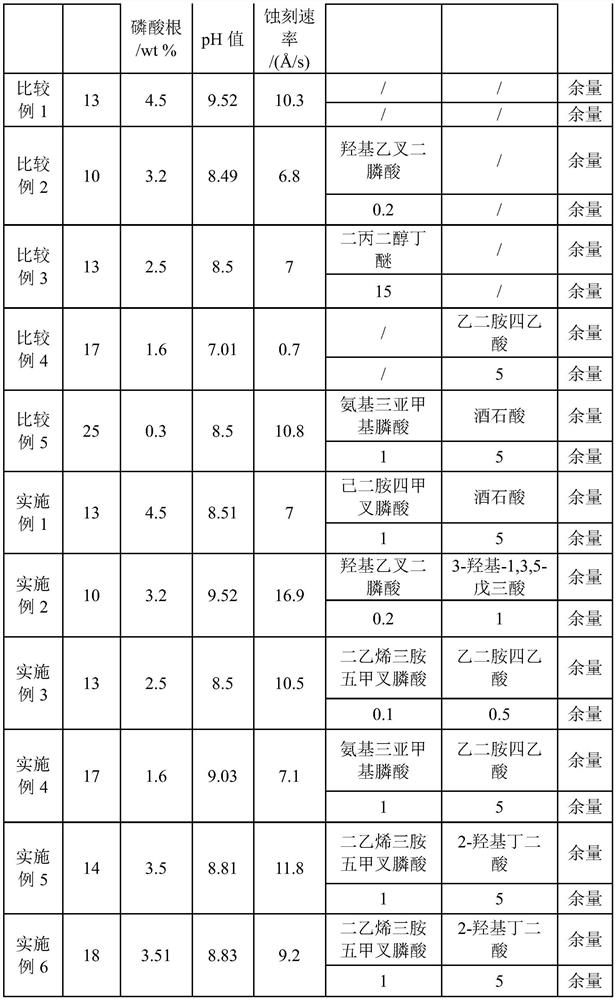

[0056] performance evaluation

[0057] Performance parameter test standard:

[0058] 1.H 2 o 2 Relative reduction, the code is K, unit %; K=(initial hydrogen peroxide content-hydrogen peroxide content at detection time point) / initial hydrogen peroxide content, expressed by K24, K48, K72, and K96 respectively for 24h, 48h, and 72h , The relative reduction of the hydrogen peroxide phase in the etching solution during 96h; the low K value is excellent, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com