Mode optimization output device based on conical optical fiber

A tapered optical fiber and exporter technology, which is applied in the field of mode-optimized exporters, can solve problems such as low cost performance of the same-band pump, improvement, and the safety impact of the optical system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solutions and advantages of the present invention clearer, the technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

[0029] The embodiment of the present invention provides a mode optimization output device based on a tapered fiber, which can be used to optimize the beam quality of the laser output from the fiber.

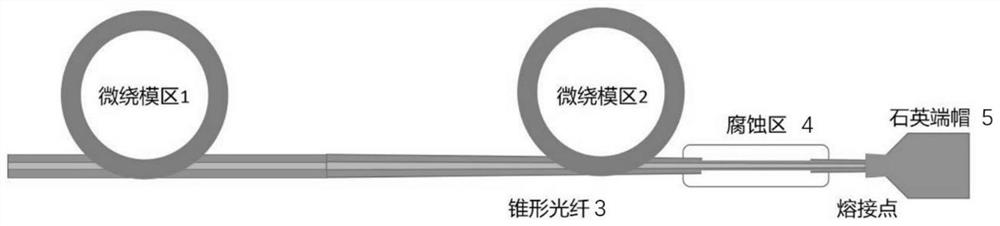

[0030] The mode-optimized output device mainly includes a first (micro) mode-wrapping area 1, a second (micro) mode-wrapping area 2, a (long) tapered optical fiber 3, an erosion area 4, an output part (the output part preferably adopts a quartz end cap 5 ). The input end of the tapered fiber is a thick end, and the output end of the tapered fiber is a thin end, that is, the tapered fiber is a fiber that gradually becomes thinner from the input end to the output end (the cladding diameter and the core diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com