Method for preparing high-precision and large-area nano structure on insulating substrate

A nanostructure technology on an insulating substrate, applied in nanotechnology, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of splicing dislocation of writing field, complex operation, and not too high resolution, and achieve a large photosensitive surface , simple process and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

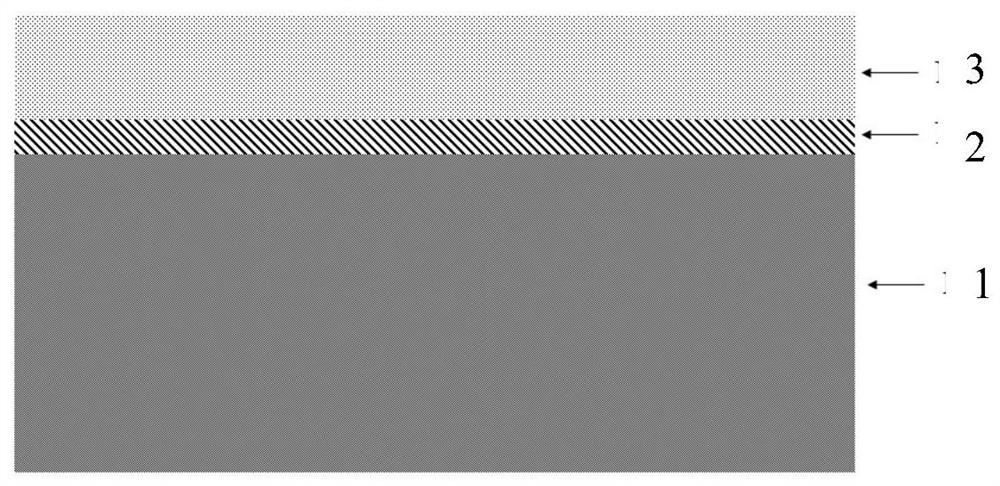

[0049] On the basis of the above method, this embodiment takes the preparation of a SNSPD with a large photosensitive surface on an insulating substrate as an example, and provides a detailed experimental operation process, including

[0050] Step 1: Use acetone, ethanol and deionized water to clean the MgO insulating substrate 1 with a thickness of 500 μm. After cleaning the MgO insulating substrate 1, blow it dry with a nitrogen gun to remove the moisture on the surface of the substrate. Use AFM to measure the MgO insulating substrate 1. The surface roughness of substrate 1 RMSfigure 1 .

[0051] Step 2: Using a DC magnetron sputtering apparatus to grow a NbN superconducting film 2 with a thickness of 5 nm on the surface of a highly clean MgO insulating substrate 1 for preparing a micro-nano structure, the grown NbN superconducting film 2 Surface roughness RMS figure 2 For the samples shown, the samples were ultrasonically cleaned.

[0052] Since the NbN superconducting thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com