A lithium battery composite separator and its preparation method and application

A composite separator and lithium battery technology, applied in the field of preparation, lithium battery composite separator, and lithium battery, can solve the problems of the peeling strength of the ceramic layer and the PVDF layer, the weakening of the peeling strength of the composite separator layer, and the limited effect of thermal stability, etc. Achieve excellent positive electrode bonding properties, good dimensional stability at high temperature, and improve peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

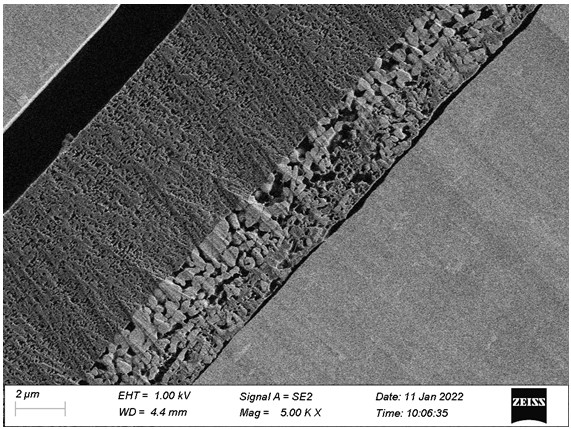

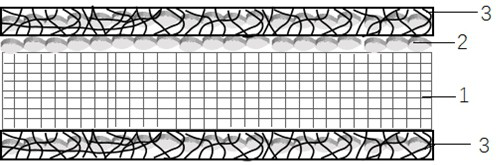

Image

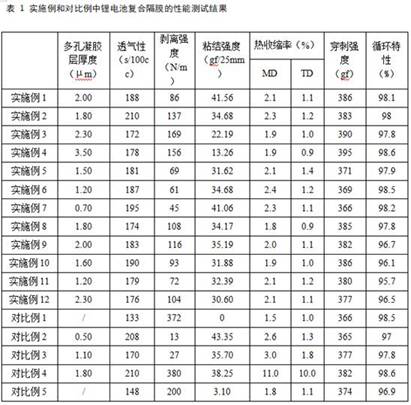

Examples

Embodiment 1

[0076] Embodiment 1 of the present invention is the preparation of a lithium battery composite diaphragm:

[0077] 1) Preparation of PVDF / ceramic hybrid slurry: Based on 100 parts by weight of the coatable slurry, 5 parts by weight of PVDF resin (3 parts by weight of PVDF resin with a weight average molecular weight of 800,000 to 1 million and 2 parts by weight of 200,000~500,000 PVDF resin), 2 parts by weight of emulsion-type acrylate adhesive dispersed in deionized water (solid content 40wt%, viscosity 20~200cps) and 7.5 parts by weight of Al 2 O 3 Particles (Dv50 of 0.64 μm) were added to a dimethylacetamide (DMAC) / water dispersion and dissolved at 50 °C for about 3 hours to form a mixed slurry of binders.

[0078] 2) Preparation of ceramic layer: use microgravure coating to coat the ceramic slurry on one side of the 7 μm base film, form a ceramic layer after drying, and obtain the ceramic film, that is, the traditional power lithium-ion battery separator (thickness 9 μm, ...

Embodiment 2

[0081] Embodiment 2 of the present invention is the preparation of a lithium battery composite separator:

[0082] 1) Preparation of PVDF / ceramic mixed slurry: Based on 100 parts by weight of the coatable slurry, 5 parts by weight of PVDF resin (2 parts by weight of PVDF resin with a weight average molecular weight of 800,000 to 1 million and 3 parts by weight of 200,000~500,000 PVDF resin), 2 parts by weight of emulsion-type acrylate adhesive dispersed in deionized water (solid content 40wt%, viscosity 20~200cps) and 7.5 parts by weight of Al 2 O 3 Particles (Dv50 of 0.64 μm) were added to a dimethylacetamide (DMAC) / water dispersion and dissolved at 50 °C for about 3 hours to form a mixed slurry of binders.

[0083] 2) Preparation of ceramic layer: use microgravure coating to coat the ceramic slurry on one side of the 7 μm base film, form a ceramic layer after drying, obtain a ceramic film (thickness 9 μm, puncture strength 366gf), a single layer of ceramic layer The coatin...

Embodiment 3

[0086] Embodiment 3 of the present invention is the preparation of a lithium battery composite separator:

[0087] 1) Preparation of PVDF / ceramic hybrid slurry: Based on 100 parts by weight of the coatable slurry, 4 parts by weight of PVDF resin and 2 parts by weight of emulsion-type acrylate adhesive (solid content 40wt) dispersed in deionized water %, viscosity 20~200cps) and 8 parts by weight of Al 2 O 3 Particles (Dv50 of 0.64 μm) were added to a dimethylacetamide (DMAC) / water dispersion and dissolved at 50 °C for about 3 hours to form a mixed slurry of binders.

[0088] 2) Preparation of ceramic layer: use microgravure coating to coat the ceramic slurry on one side of the 7 μm base film, form a ceramic layer after drying, obtain a ceramic film (thickness 9 μm, puncture strength 366gf), a single layer of ceramic layer The coating thickness is 2.0 μm.

[0089] 3) Preparation of composite diaphragm: under the conditions of 23 ° C and 20% relative humidity, the mixed slurr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com