Roughening treatment technology for surface of bone implantation prosthesis

A technology of bone implantation and roughening, applied in the direction of prosthesis, medical science, etc., can solve the problem of unsolvable coating detachment, oxide layer on the surface of the product, affecting the healing cycle of the product, etc., to achieve long-term stability. , reducing the risk of escape, reducing the effect of biological risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

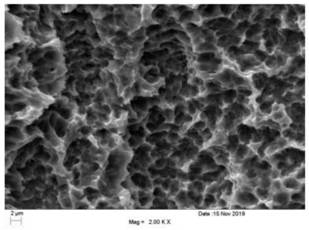

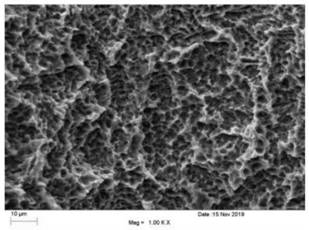

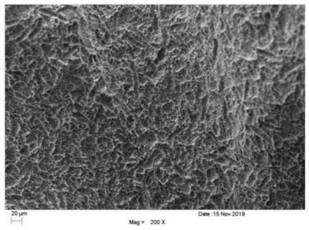

Image

Examples

Embodiment 1

[0033] S1. The bone implant prosthesis made of pure titanium is sprayed for 0.5min at room temperature under a pressure of 0.5Mpa, and the spray medium is titanium oxide particles with a particle size of 5 mesh; a layer of oxide film is formed on the surface of the prosthesis after high-pressure spraying ;

[0034] In the specific implementation process, dry spraying can be selected during spraying in this step (directly using compressed air as power to form a high-speed spray beam to spray Ti 2 O spray) or wet sandblasting (compressed air is used as power to form a high-speed jet beam to spray Ti 2 A mixture of O and water is ejected);

[0035] S2. Soak in solution A made of concentrated nitric acid, concentrated hydrofluoric acid and water according to the ratio of x:y:100-x-y (where x is 1, y is 1) and soak at 20°C for 10 minutes, then go through step S1 The obtained bone implant prosthesis uses the strong corrosiveness of solution A to remove the oxide layer on the surfa...

Embodiment 2

[0039] S1. The bone implant prosthesis made of cobalt-chromium-molybdenum was sprayed for 1.5 minutes at room temperature under a pressure of 2Mpa, and the spray medium was molybdenum oxide particles with a particle size of 60 mesh; a layer of oxide film was formed on the surface of the prosthesis after high-pressure spraying;

[0040] In the specific implementation process, dry spraying can be selected during spraying in this step (directly using compressed air as power to form a high-speed spray beam to spray Ti 2 O spray) or wet sandblasting (compressed air is used as power to form a high-speed jet beam to spray Ti 2 A mixture of O and water is ejected);

[0041] S2. Use concentrated nitric acid, concentrated hydrofluoric acid and water according to the ratio of x:y:100-x-y (where x is 3, y is 3) and soak in solution A at 30°C for 18 minutes, then step S1 The obtained bone implant prosthesis uses the strong corrosiveness of solution A to remove the oxide layer on the surfa...

Embodiment 3

[0045] S1. Spray the bone implant prosthesis made of pure titanium at room temperature for 3 minutes under a pressure of 3Mpa, and the spray medium is titanium oxide particles with a particle size of 100 mesh; a layer of oxide film is formed on the surface of the prosthesis after high-pressure spraying;

[0046] In the specific implementation process, dry spraying can be selected during spraying in this step (directly using compressed air as power to form a high-speed spray beam to spray Ti 2 O spray) or wet sandblasting (compressed air is used as power to form a high-speed jet beam to spray Ti 2 A mixture of O and water is ejected);

[0047] S2. Soak in solution A made up of concentrated nitric acid, concentrated hydrofluoric acid and water according to the ratio of x:y:100-x-y (where x is 5, y is 5) and soak at 40°C for 25 minutes and go through step S1 The obtained bone implant prosthesis uses the strong corrosiveness of solution A to remove the oxide layer on the surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com