Waterborne polyurethane resin emulsion, preparation method and earphone cover leather

A water-based polyurethane and resin emulsion technology, which is applied in the field of water-based polyurethane, can solve the problems of narrow processing range, inability to meet the high-frequency processing performance requirements of earphone cover leather, and low strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

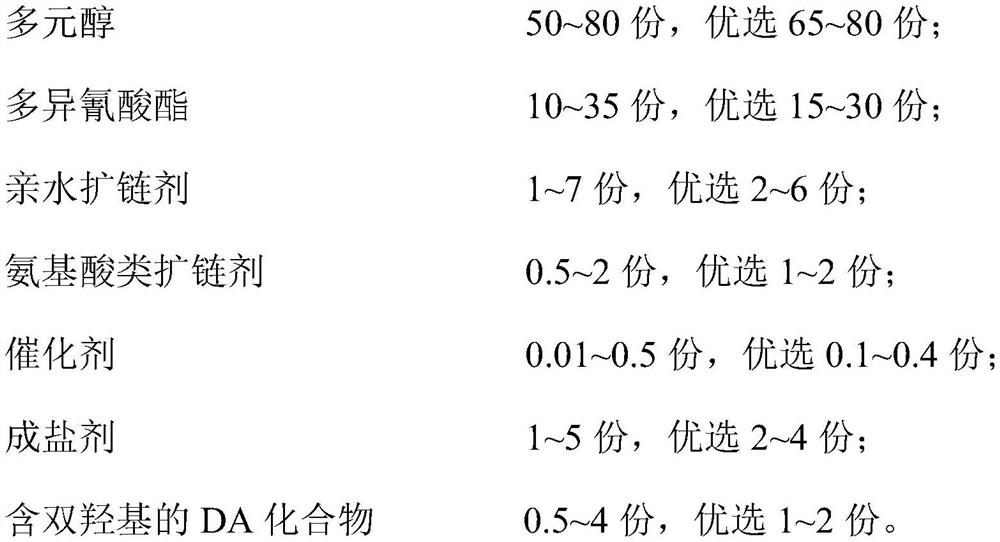

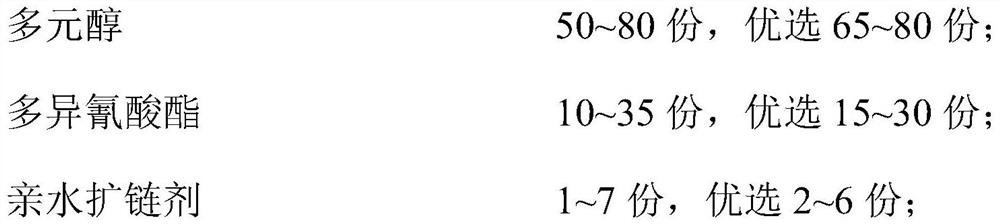

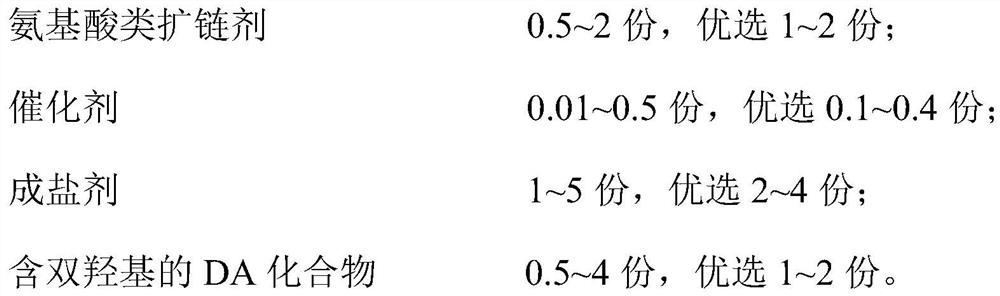

Method used

Image

Examples

Embodiment 1

[0049] Dehydrate 100g (0.05mol) of polytetrahydrofuran ether polyol (molecular weight: 2000) at 105°C for 1 hour, then cool down to 50°C, add 40g (0.15mol) of dicyclohexylmethane diisocyanate, heat up to 90°C and keep warm for reaction 3 Hours, measure NCO content, reach theoretical value 6.16, then cool down to 50°C, then add 6g (0.04mol) dimethylol butyric acid, 1.48g (0.01mol) lysine to react at 80°C for 2h, cool down to 50°C, then add 0.2g organic bismuth Coscat83 and 2.3g (0.008mol) And add 10ml of acetone to adjust the viscosity, react at 70°C for 2.5h, then cool down to 0°C, add 3.5g of triethylamine for neutralization, after neutralization for 10min, add 350g of deionized water under high-speed shear at 1500rpm, and disperse for 7min , the final NCO value was 1.7, and the acetone and part of the water in the system were distilled off under reduced pressure to obtain an aqueous polyurethane resin emulsion 1 with a solid content of 35%.

Embodiment 2

[0051] Dehydrate 50g (0.035mol) of polytetrahydrofuran ether polyol (molecular weight: 1500) and 50g (0.02mol) of polypropylene oxide polyol (molecular weight: 2500) at 110°C for 1h, then cool down to 50°C, add 35g ( 0.14mol) of diphenylmethane diisocyanate, heat up to 90°C for 3 hours, measure the NCO content, after reaching a theoretical value of 10.43, cool down to 50°C, then add 4g (0.03mol) dimethylol butyric acid, 1.2g (0.008mol) lysine was reacted at 75°C for 2h, cooled to 50°C, and then 0.2g organic bismuth Coscat83 and 1.5g (0.006mol) And add 8ml of acetone to adjust the viscosity, react at 70°C for 2.5h, then cool down to 0°C, add 4g of triethylamine for neutralization, after neutralization for 10min, add 325.7g of deionized water under high-speed shear at 1500rpm, and disperse for 5min , the final NCO value was 1.7, and the acetone and part of the water in the system were distilled off under reduced pressure to obtain an aqueous polyurethane resin emulsion 2 with a...

Embodiment 3

[0053] Dehydrate 85g (0.043mol) of polypropylene oxide polyol (molecular weight: 2000) at 100°C for 2 hours, then cool down to 50°C, add 30g (0.115mol) of dicyclohexylmethane diisocyanate, heat up to 85°C and keep it warm for reaction After 3.5 hours, measure the NCO content, cool down to 50°C after reaching the theoretical value of 5.26, then add 2.5g (0.019mol) of dimethylol butyric acid, 2g (0.014mol) of lysine and react at 75°C for 2h, then cool down to 50°C, then add 0.25g organic bismuth Coscat83 and 1.2g And add 4ml of acetone to adjust the viscosity, react at 75°C for 2h, then cool down to 0°C, add 2.5g of triethylamine for neutralization, after neutralization for 10min, add 299.8g of deionized water under high-speed shear at 1500rpm, and disperse for 10min , the final NCO value was 1.60, and the acetone and part of the water in the system were distilled off under reduced pressure to obtain an aqueous polyurethane resin emulsion 3 with a solid content of 32%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com