Antifouling self-cleaning face coating agent and antifouling self-cleaning face coating ETFE film with lotus leaf effect

An ETFE film, self-cleaning technology, applied in the direction of coating, etc., can solve the problems of reduced strength and shortened life of materials used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

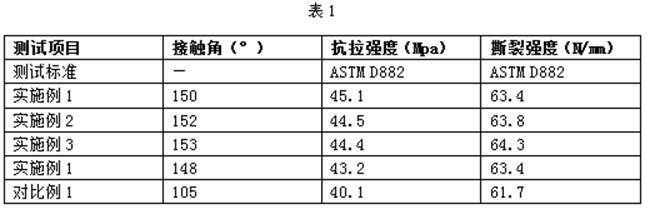

Examples

Embodiment 1

[0022] S1: Using orthoethyl silicate (TEOS) as the precursor, TEOS, DMF, H 2 0 The mass ratio is 1:6:0.4; the reaction temperature is 60°C, the hydrolysis time is 3h, the pH value is 11, and after standing for 3~5 hours, add water and oil repellent FK510 dropwise to form a wet gel; the sol and FK510 wet gel The glue mass ratio is 99:1;

[0023] S2: Dry at 100°C for 8h, and then treat at 300°C for 30min to obtain SiO 2 -FK510 powder;

[0024] S3: Using water and ethanol as the solvent, hydrochloric acid as the catalyst, hydrolyze the silane coupling agent, and use the hydrolyzed product to degrade SiO 2 -FK510 composite powder for modification;

[0025] S4: 50g ethanol, 5g silane coupling agent, 5g distilled water, stir evenly, add 1g SiO 2 - FK510 powder, ultrasonic dispersion for 20 minutes, magnetic stirring for 3 hours, and finally an anti-fouling self-cleaning paint;

[0026] S5: Apply the above anti-fouling self-cleaning surface coating agent to the ETFE film through...

Embodiment 2

[0031] S1: Using orthoethyl silicate (TEOS) as the precursor, TEOS, DMF, H 2 0 The mass ratio is 1:6:0.4; the reaction temperature is 60°C, the hydrolysis time is 3h, the pH value is 12, and after standing for 3~5 hours, add water and oil repellent FK510 dropwise to form a wet gel; the sol and FK510 wet gel The mass ratio of glue is 95:5;

[0032] S2: Dry at 100°C for 8h, and then treat at 300°C for 30min to obtain SiO 2 -FK510 powder;

[0033] S3: Using water and ethanol as the solvent, hydrochloric acid as the catalyst, hydrolyze the silane coupling agent, and use the hydrolyzed product to degrade SiO 2 -FK510 composite powder for modification;

[0034] S4: 50g ethanol, 5g silane coupling agent, 5g distilled water, stir evenly, add 1g SiO 2 - FK510 powder, ultrasonic dispersion for 20 minutes, magnetic stirring for 3 hours, and finally an anti-fouling self-cleaning paint;

[0035] S5: Apply the above anti-fouling self-cleaning surface coating agent to the ETFE film thro...

Embodiment 3

[0040] S1: Using orthoethyl silicate (TEOS) as the precursor, TEOS, DMF, H 2 0 The mass ratio is 1:6:0.4; the reaction temperature is 60°C, the hydrolysis time is 3h, the pH value is 12, and after standing for 3~5 hours, add water and oil repellent FK510 dropwise to form a wet gel; the sol and FK510 wet gel The mass ratio of glue is 93:7;

[0041] S2: Dry at 100°C for 8h, and then treat at 300°C for 30min to obtain SiO 2 -FK510 powder;

[0042] S3: Using water and ethanol as the solvent, hydrochloric acid as the catalyst, hydrolyze the silane coupling agent, and use the hydrolyzed product to degrade SiO 2 -FK510 composite powder for modification;

[0043] S4: 50g ethanol, 5g silane coupling agent, 5g distilled water, stir evenly, add 1g SiO 2 - FK510 powder, ultrasonic dispersion for 20 minutes, magnetic stirring for 3 hours, and finally an anti-fouling self-cleaning paint;

[0044] S5: Apply the above anti-fouling self-cleaning surface coating agent to the ETFE film thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com